Gulf of Mexico (GoM) deepwater wells present the potential to encounter a variety of drilling-related challenges, including gas hydrates, wellbore instability, ROP, lost circulation and pressure control. Management of these challenges is paramount toward execution of a strategy to reduce nonproductive time (NPT) and to safely achieve drilling objectives and project economics. Additionally, operational activities in the GoM are conducted within the regulatory framework of the Bureau of Ocean Energy Management and the Bureau of Safety and Environmental Enforcement.

Newly implemented regulations for offshore drilling in the GoM increased focus on the physical properties of drilling fluids to ensure adequate pressure control is maintained. Pressure control is particularly important in deepwater operations where a narrow window exists between the pore pressure and the fracture gradient. These narrow margin wells are abnormally pressured, and the design characteristics of drilling fluids for deepwater wells are unique and can differ significantly compared to the requirements for normally pressured wells.

Deepwater drilling fluid design challenges are exacerbated by the operational conditions typically encountered in the execution of drilling operations. The cooling effects of the water column opposite the riser creates a negative geothermal gradient, where static temperatures are often reduced to as low as 4 C (40 F) at the seafloor. The geothermal gradient then increases with increasing depth, with bottomhole static temperatures in excess of 149 C (300 F) frequently encountered. Increasingly, the fluids of choice by operators in the GoM deepwater operations are characterized as flat or constant rheology fluids designed to achieve drilling performance objectives and manage risks inherent to drilling in a narrow pressure environment.

Newpark’s Kronos is a flat (constant) rheology system designed specifically for use in challenging deepwater wells. It is an environmentally sound nonaqueous drilling fluid with the flexibility to address a broad range of operational requirements.

More than a fluid

The Kronos drilling fluid system can be readily formulated with a variety of synthetic-based fluids, grades of barite and type of brines. Robust fluid formulations are built through use of novel and proprietary emulsifiers, rheological modifiers, suspension agents and fluid loss additives. The system is nearly independent of changes of temperatures and pressures typically encountered in deepwater drilling operations.

Variations in rheological properties such as plastic viscosity, yield point, as well as viscometer dial readings of 3 rpm and 6 rpm and gel strengths, are minimized in Kronos to safely achieve drilling, tripping and casing running objectives without incidents of fluids-related NPT.

The benefits of the Kronos flat rheology system are further enhanced through use of the HyCalc engineering software platform by allowing greater operational efficiency while also reducing the potential for lost circulation. The HyCalc software is extensively used in prewell planning operations. During the planning stage, the software is used to model the operational environment and to ensure that hole cleaning, barite sag, equivalent circulating density (ECD) management and swab/surge objectives are satisfied prior to commencement of drilling activities. The use of the HyCalc system continues during the wellbore construction process. Surface fluid properties and operating conditions are frequently updated to predict downhole hydraulic-related annular profiles. Internal knowledge of the Kronos system’s HP/ HT properties coupled with a rheology calibration procedure enhance HyCalc’s ability to accurately predict ECD values in comparison to downhole measured values.

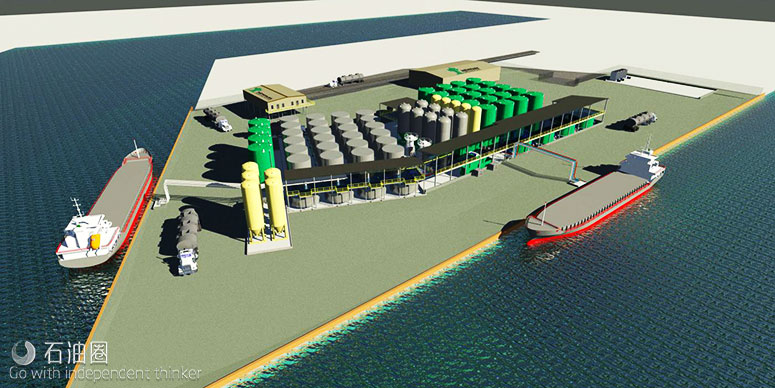

Another key enabler in the drilling fluids value chain is facility placement, capability and capacity. Operators leverage best-in-class distribution and logistics provided by offshore supply bases to improve project efficiencies and economics. Understanding the logistical and operational challenges associated with deepwater projects, Newpark Resources invested in an offshore supply base in Port Fourchon, La. Able to address the growing deliverability requirements for the GoM deepwater market, the supply base can manufacture and simultaneously offload large volumes of drilling fluids to multiple supply vessels at rates surpassing competitive facilities, leading to a more cost-effective solution.

Precise, real-time metering with monitoring and control abilities allows the plant operators to be wellinformed while keeping the important process decisions simple, timely, accurate and reliable. A rapid salt delivery system and improvements in mixing and shearing techniques, along with reconfigured piping and pump arrangements, have allowed parallel processing and advances in both lead time and capacity.

Overall faster turnaround in loading and unloading boats also was achieved. Upgrades to mixing equipment have produced a more stable fluid, which ensures the rheological quality of the drilling fluid is maintained between offloading and utilization at the rig site.

Case study

Newpark recently demonstrated its ability to integrate and leverage its Kronos flat rheology system for a multinational company in a GoM deepwater well in more than 1.6 km (5,500 ft) of water. The system was chosen following a rigorous and demanding approval process. Key operational parameters in the prewell planning phase included displacement efficiency, contamination, tight tolerances and management of static and dynamic barite sag. A Kronos fluid was designed and tested at the Newpark Technology Center over several weeks. Laboratory testing ensured that all rheological, filtration control, emulsion stability and barite sag design parameters were optimized in advance preparation of the Kronos system at the Port Fourchon supply base.

The rheological and emulsion stability properties of the Kronos flat rheology fluid were optimized at the supply base through use of an inline shearing device. Placement of the shearing device in the Kronos design process ensures delivery of a robust and fit-for-purpose fluid upon delivery, eliminating the need to circulate and shear through the drillbit. The performance of Kronos on this well met the performance expectations of the company.

The system proved to be robust and easy to maintain within specifications in all phases of the operation. A true measure of robustness of nonaqueous fluids is the ability to handle interfaces and contaminants, such as seawater and cement spacers, and the Kronos system was able to maintain a flat rheological profile despite encountering these contaminants. The ability of the Kronos fluid to manage barite sag was best observed when the standby Kronos fluid was offloaded following completion of the campaign. This contingency Kronos fluid was stored on the supply vessel for 44 days. Settling or sedimentation did not occur despite being subject to slow and continual motion on the vessel.

石油圈

石油圈