Taking Reservoir Characterization To The Next Level

Reservoir characterization, the process operators undertake to understand rock and fluid properties, is arguably the most critical component of field development planning because it is key to ensuring optimal production and recovery over the lifetime of the well. As operators have ventured into more complex fields, the service industry has responded by developing increasingly sophisticated tools and technologies for conducting the full spectrum of seismic surveys, wireline logging, fluid and core sampling and analysis, modeling, and well performance simulation to reduce uncertainties concerning the subsurface and reservoir producibility.

To meet the characterization challenges of increasingly intricate operating environments, Schlumberger recently expanded its Reservoir Laboratory in Houston to strengthen the integration of rock and fluid analysis services by bringing together the company’s portfolio of reservoir characterization tools under one roof. The services span the entire reservoir characterization process across the hydrocarbon life cycle, from digitally enabled field sampling to measurement and modeling. In addition to an optimized set of measurements and analysis, customers have access to innovative solutions, digital models and geoscience expertise.

The laboratory is staffed by scientists, engineers and technicians working across the spectrum of reservoir rock and fluid analysis. (Source: Schlumberger)

Digital, integrated approach

Despite numerous advances in the industry, the ability to easily access, understand and synthesize the various data sources into a representative picture of the reservoir to make more meaningful decisions remains a challenge.

Schlumberger is replacing this piecemeal procedure with an integrated reservoir characterization strategy that provides the capability to combine field data and laboratory measurements in the DELFI cognitive E&P environment, a secure, cloud-based space that harnesses data, scientific knowledge and expertise to facilitate collaboration among E&P teams. The digital applications being implemented for data integration in turn facilitate comprehensive rock and fluid modeling and interpretation for greater reservoir insight that enhances field development from pore to pipeline.

This approach was successfully applied in a complex deepwater field in the Gulf of Mexico (GoM), reducing uncertainty and risk for the operator. The field comprises upper and lower sands separated by a significant shale layer, which presented connectivity and completion design challenges.

The integrated reservoir evaluation solution brought together multiple disciplines and technologies including seismic surveys, wireline logging data and a fluid geodynamic workflow incorporating precise laboratory measurements of fluid and geochemical properties to derive the geologic model for reservoir simulation. The model was calibrated to achieve a match between the simulated and historical production and pressure data. Reservoir simulation confirmed connectivity between the upper and lower sands, which aided the operator in optimizing wellbore placement and designing an effective completion, resulting in savings of more than $50 million.

Sampling for complete fluid characterization

Fluid analysis begins with sampling reservoir fluids. The Saturn 3-D radial probe establishes and maintains 3-D circumferential flow in the formation around the borehole. This enables accurate pressure measurements, downhole fluid analysis, sampling and permeability estimates, especially in challenging formations where the use of conventional wireline testing techniques is not possible. In an unconsolidated laminated GoM reservoir, a 9-in. Saturn probe collected clean single-phase hydrocarbon samples with very little contamination while taking only 2.5 hours for cleanup and sample acquisition.

In addition to openhole sampling, while-drilling analysis and sampling capabilities have been developed for the integrated reservoir characterization strategy. SpectraSphere fluid mapping-while-drilling service, which provides downhole fluid composition and pressure measurements in real time while drilling, provides operators with the earliest possible insight to reservoir fluids. Deployed in the Mississippi Canyon to enhance formation pressure testing and sampling, the service collected and analyzed six samples downhole in real time. This was an industry first for the transmission of detailed in situ fluid properties, saving the operator from waiting for two to three months to receive conventional fluid analysis.

The Schlumberger Reservoir Laboratory provides a range of physical and digital rock and fluid analysis services for the life of the reservoir. (Source: Schlumberger)

Optimized measurement sets

Paralleling the growth of the portfolio of downhole rock and fluid measurements, technologies and workflows are similarly being implemented in the laboratory with the goal of increasing reservoir knowledge through enhanced measurement efficiency and data reliability.

For example, while new workflows decrease the number of physical laboratory tests required by the incorporation of in situ measurements, they also provide compositional information that increases confidence in the equation-of-state models the data are input into. The growing use of automation not only helps improve efficiency and thus accelerates access to information, but it also increases reliability and, more importantly, implements the process of digitization.

Further expanding the integrated reservoir characterization portfolio is expertise provided by Fluid Inclusion Technologies (FIT), a Schlumberger company specializing in laboratory analysis of trapped fluids in rock material. FIT uses a technique specifically suited for resolving the small concentrations of oil and gas species that are represented in the fluid inclusions, which enables documenting and mapping petroleum migration and charge events. In unconventional reservoirs in particular the information gained helps to guide completion decisions based on anticipated production. The overall workflow is fully automated and includes elemental analysis and high-resolution imaging for a complete overview.

Comprehensive 3-D modeling

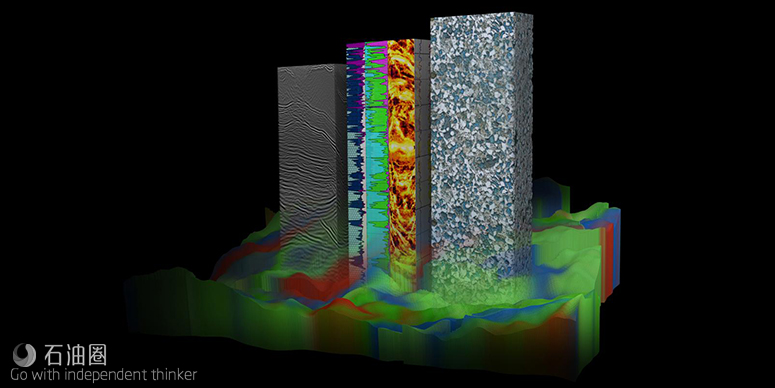

The reservoir characterization portfolio also includes CoreFlow digital rock and fluid analytics services, which integrate physical and digital rock and fluid analyses to create a holistic 3-D rock model that facilitates dynamic flow simulation for evaluating multiple hydrocarbon release scenarios to enable faster and better-informed decisions. The technology provides input such as relative permeabilities and capillary pressures for reservoir simulators. The pore-scale compositional simulator extends the envelope of analysis beyond the scope of physical analysis. This is particularly impressive in unconventional EOR applications, where traditional laboratory analysis reaches its current limits. Recent projects in the Eagle Ford provided operators with revised theoretical hydrocarbon release limits and an optimized approach for gas injection.

Despite the importance of fluid properties in design calculations, operators have often experienced difficulties modeling these properties because of poor software usability, deficient interchangeability between models and a lack of standardized and consistent workflows. For accurate fluid modeling throughout the reservoir life cycle, Schlumberger has released the FluidModeler application in the DELFI environment. In addition to consistent fluid analysis and modeling that combines downhole measurements, laboratory fluid analysis, software solutions and consulting services, this environment provides a new way of working for teams, enabling cross-collaboration among the geology, geophysics, reservoir engineering, drilling and production domains while leveraging the full potential of available data to optimize E&P assets.

石油圈

石油圈