Maximizing Equipment And Component Life In Extreme Oil And Gas Environments

Over the last decade, a lack of material traditional hydrocarbon discoveries coupled with declining reserves has incentivized the oil and gas industry to develop new economically viable techniques to optimize extraction from increasingly challenging geologies and geographies.

In such hostile environments, and bearing the brunt of shock loads and high pressures, components can become deformed, causing fractures, chipping and catastrophic equipment malfunction. In addition, seawater, sour oil and gas containing aggressive H2S, other grades of crude containing CO2, and acidic fluids can quickly cause corrosive attacks which, especially when combined with abrasion or erosion, can significantly accelerate corrosion and lead to premature part failure.

Existing coating alternatives range from high-velocity oxy-fuel (HVOF), hard chrome plating (HCP) and physical vapor deposition to emerging processes such as electroless nickel composite plating and explosive bonding. However, although successful in some applications, each has its limitations.

The Hardide-T chemical vapor deposition (CVD) coating, which is typically used in the oil and gas industry, outperforms these alternatives in a number of critical areas. It belongs to a novel family of nanostructured tungsten/tungsten carbide coatings that are used on components subjected to high levels of wear, erosion, corrosion, galling and shock loading.

The coating can be used in applications calling for smooth external and internal surfaces, and on many complex shapes, including downhole tools, fracturing tools, retrievable packers, actuators, control valves and subsea pumps.

It is crystallized atom by atom from low-pressure gas media, producing a uniform, pore-free coating—a result of the highly mobile reaction products filling micropores and defects as it grows—which does not need to be sealed.

The dispersed tungsten carbide nanoparticles give the material enhanced hardness, which can be controlled and tailored to give a typical range of between 800 Vickers and 1,600 Vickers hardness for different coating types. The CVD coating is typically applied at a thickness of 50 μm.

Testing

In testing the CVD coating provided enhanced protection against corrosion, wear, erosion, acids and other chemically aggressive media. It also displayed improved fatigue life and toughness.

Traditionally used coatings such as HCP, thermal spray and electroplating have micropores and microcracks that can widen under load, allowing media to attack the substrate. Sealing can improve the corrosion resistance, but there are several limitations including—in the case of organic sealants—maximum use temperature.

Plus, as the coating wears, deeper, previously concealed, unsealed pores will eventually open.

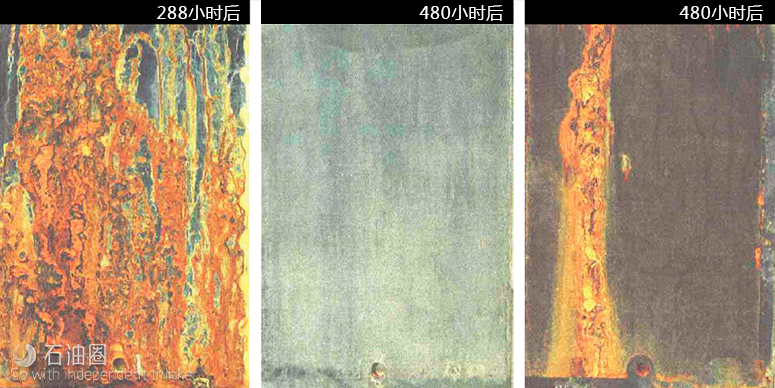

The pore-free CVD coating’s performance was confirmed in accordance with the ASTM B117-07a standard. Mild steel plates were coated with HCP, HVOF and CVD coatings and were subjected to 480-hour neutral salt spray tests. The HCP samples were badly corroded and were removed from the test after just 288 hours of exposure. The HVOF-coated samples showed heavy rust stains and the coating blistered due to intensive corrosion of the steel plate beneath. CVD samples showed only light staining.

The HVOF tungsten carbide-cobalt (bottom) has 2.55% porosity, and the CVD tungsten carbide coating (top) has 0% porosity. (Source: Hardide Coatings)

Samples of three different coatings after salt spray corrosion tests are shown: hard chrome (left) after 288 hours, CVD tungsten carbide coating (middle) after 480 hours and HVOF (right) after 480 hours. (Source: Hardide Coatings)

Galling prevention

The CVD tungsten carbide coating’s galling resistance was tested using a Phoenix TE77 high-frequency reciprocating test rig. The test uses the reciprocating dry sliding movement of a cylinder on a flat plate with loads gradually increasing from 10 N up to 800 N—equivalent to 810.2 mega Pascal contact pressure—and monitors the coefficient of friction (CoF), where above 1.0 indicates severe galling.

In comparison with a baseline control test using a stainless steel pin, which was stopped due to sample seizure after reaching critical 1.0 CoF quickly with just a 65 N load, when a CVD-coated pin was tested against a coated plate, the dry friction coefficient remained low: stabilizing at about 0.2.

Importantly, no galling was observed even under the test rig’s maximum load.

In contrast, the steady-state dry friction coefficient of HCP was reported at 0.70+/-0.1, more than three times higher, with spray coatings’ dry friction range stated as 0.56 to 0.61.

Sulfide stress cracking

The CVD coating was tested by Bodycote Materials Testing for resistance to aggressive media in accordance with the NACE standard (TM0177-2005/ASTM G39) 30-day sulfide stress cracking test. This test is performed in a solution of 5 wt% sodium chloride and 0.5 wt% acetic acid saturated with H2S. Samples were tested in deformed conditions with coating elongation up to 3,000 microstrains. During the test, the uncoated sample cracked across the full 20-mm width and experienced extensive microcracking and pitting, while the CVD-coated substrate showed no micro- or macrocracking or degradation.

Resistance to deformations, impact and wear

During micro and nano-scale testing, the coating sample did not fracture after 100 nano-impacts, and a diamond cube corner indentation failed to induce cracks. In neither test did the coating exhibit brittle behavior, thus its fracture toughness exceeded the level that can be measured using commonly used methods.

Wear resistance tests performed in accordance with the ASTM G65 standard showed the coating wear rate is 40 times lower than abrasion resistant steel, 12 times lower than hard chrome and four times lower than thermal spray.

Real world capability, potential for growth

In September 2017 Hardide Coatings announced a collaboration with Master Flo Valve Inc. (MFV) to protect HP/HT subsea choke valves.

The flow management company needed a new coating solution for its choke valves’ stem assemblies. The coating needed to be rated to temperatures as high as 204 C (400 F)—a requirement that eliminated all standard coating options—and be capable of withstanding pressures up to 20,000 psi. Resistance to wear, corrosion and erosion were all critical. Plus, the coating needed to be durable and be able to be polished to an extremely smooth finish.

All these properties were crucial to preserving the tool’s metal-to-metal seal, which needed to operate reliably over hundreds of cycles in subsea environments, such as single or multiphase production as well as water, chemical or gas injection.

Now the CVD coating is used to hardface stems on the MFV P4-15k and P4-20K subsea bolted bonnet choke valves as well as on an application for a capping stack, for deployment in a blowout situation.

石油圈

石油圈