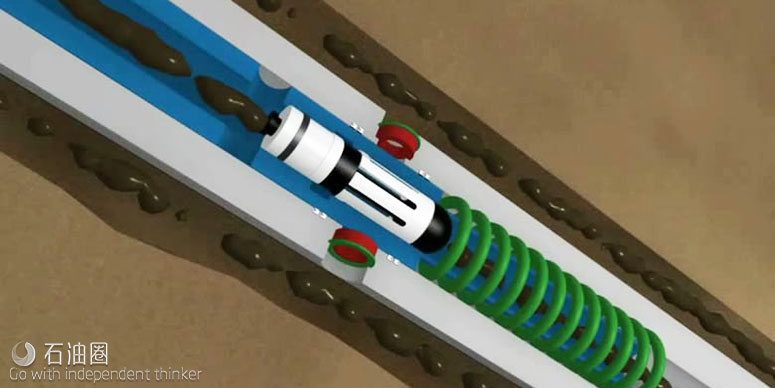

The DAV MX™ is a multi-function, multi-cycling circulating sub which is activated with our patented MX™ Smart Dart technology. The system raises the bar on performance and reliability without adding complexity for the user. With several patented features, such as hold open and latch & seal, the tool is clearly the smart choice for CircSub users.

Class leading reliability is delivered by a range of robust dart options pumped into a simple rugged sub and catcher. The tool is extremely user-friendly with no need for configuration prior to use – simply drop the required dart to ‘plug and play’. In Deepwater, HPHT and High Angle operations, the speed and performance of the DAV MX™ has delivered thousands of hours of savings across the globe.

The Smart Choice:

• Versatile – our range of Smart Darts provides users with split flow, full-bypass and well control options for a countless number of applications.

• Reliable – unlike with conventional balls, DAV MX™ darts will not blow-thru on opening therefore can be pumped down at much higher speeds.

• Simple – the tool is simple and easy to operate, requiring no service hand.

• Performance – the DAV MX™ cycling is largely immune to variations in angle, temperature, pressure, mud type and weight, meaning it can be run in virtually any environment and for endless applications.

DAV MX™ – Alternative Diverter Dart

Shorter than the Standard Diverter Dart, this dart allows the valve to close with the pumps off, closing off the annulus. Although it makes the valve do more work, it may be preferred in certain situations to keep the annulus shut out when the pumps are off.

• Rapid 100% bypass

• Selection rate 12%

• 8 inches in length

• Best for*: U-tube avoidance

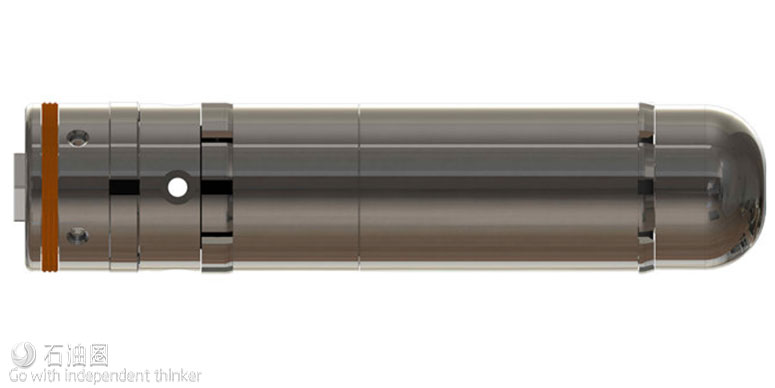

DAV MX™ – Emergency Shut-Off Dart

Not only does the DAV MX™ push the operating envelope further and have the best reliability in class, it also provides a totally unique back-up closing system. Should the valve become damaged by any unexpected events, users can deploy the Emergency Shut-Off Dart which patches and seals the leak path but still provides a generous thru-bore allowing operations to continue. The ESD ultimately saves the Operator a trip out of hole.

• Unique Repair downhole dart allowing you to “Pump Patch Pump”

• Pump into place, Patch the Leak Path, Pump through the generous through bore and continue operations

• A genuine trip saving dart

• 12 Inches in Length

• Seals on outside, generous through bore on the inside.

DAV MX™ – Split Flow Dart

The best method for DAV MX™ hole cleaning, by delivering some flow to the bit also in a hold-open mode. This BHA flow gives cooling for rotation friction in the BHA as the string which is useful for better agitation and string management.

• Rapid split flow bypass

• Selection rate 32%

• 12 inches in length

• Best for*: Agitated Hole Cleaning and Tripping into Hole.

DAV MX™ – Standard Diverter Dart

The standard method for DAV MX™ bypass, delivering 100% BHA bypass with in a hold-open mode. The default dart to use unless looking specifically for split flow or full pressure relief.

• Rapid 100% bypass

• Selection rate 56%

• 12 inches in length

• Best for*: Losses, Tripping Out Dry and Jetting BOP’s

DAV MX™ – Ultra Series

The Ultra Series Dart is capable of high speed activation, allowing it to be pumped in at up to 400gpm which is ideal for ERD (Extended Reach Drilling). It also has a low shear out pressure (600PSI) which makes it the perfect dart for delicate formations or coring runs.

• Fastest 100% Bypass (pump in at upto 400gpm)

• Soft Shear – Ideal for delicate formations

• 12 Inches in Length

• Best for ERD, Fragile formations or coring

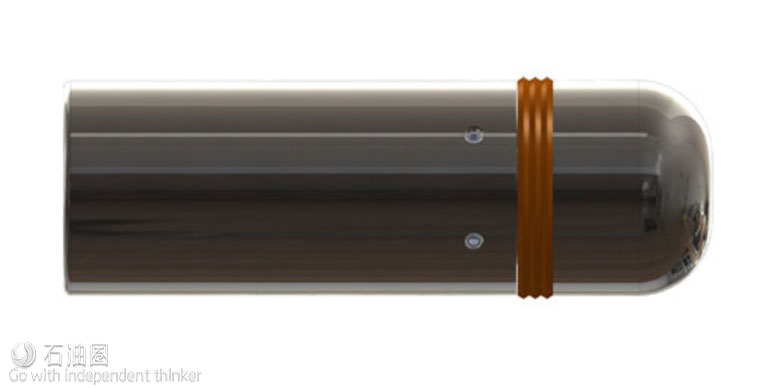

DAV MX™ – Universal Closing Dart

Whichever opening dart is used the Universal Closing Dart will shear it out to close the DAV, with both darts landing in the catcher below. It operates with full bore sealing above the opening dart to provide maximum load onto the concentrator button on the lower dart to shear out the pins.

• Rapid return to thru-bit flow

• 8 inches in length

Case Study

The DAV MX™’s resilience, versatility, speed and reliability, which are enabling clients to cut operating time, was put to the test recently by a European operator in a challenging onshore geothermal well in the Netherlands.

Optimal hole cleaning was essential given the challenging multi-tapered casing profile of the string. By deploying two DAV MX™ CircSubs, the operator boosted annular velocity and optimized its hole cleaning process across two separate runs. It cut the time to transport cuttings to the surface by around 50% if using a single CircSub and 75% if no CircSub was in the string. In optimizing the hole cleaning process the operator also prevented any concern of managing a stuck pipe situation.

During the first 6” section drillout run the operator activated the lower DAV MX™, positioned in the BHA, providing an annular velocity boost and flushed cuttings to above the 9 5/8” x 7” liner. The client then activated the upper DAV MX™, placed higher up the drill string, to lift the cuttings to surface before cycling back to its closed position. The same sequence was carried out during the subsequent 6” x 8 1/2” hole enlargement run using another two CircSubs. In total, four DAV MX™ CircSubs were successfully activated across the two runs.

The client said it was pleased with the DAV MX™’s performance and observed a significant increase in cuttings returns after each activation.

The operator also used the lower placed CircSub’s unique lock open feature on each run for dry tripping, achieving safer rig floor conditions and cutting tripping out time.

As always, the operator had a big safety margin because of the DAV MX™’s Emergency Shut-Off Dart (ESD), a unique fail-safe feature used on the rare occasions an operator has to push beyond the performance envelope and the valve becomes damaged. As usual, it was not deployed, but knowing the ESD could seal any leak paths, maintain thru-bore and allow the programme to continue without pulling out of hole, gave the operator additional confidence to complete an ambitious by-pass strategy.

Churchill’s European regional account manager, Corin Lewsey, said: “We’re pleased our DAV MX™ CircSub continues to help operators drill faster, more efficiently and at low risk.

“In this case, the operator demonstrated that running two CircSubs in the string can be a more reliable and effective method of hole cleaning and saves significant rig time. In 2018 we expect to see this trend increase significantly, especially among the many operators across the globe who are already running one DAV MX™ and benefiting from the tool’s simplicity, speed and reliability.”

In 2017 operators carried out more campaigns running the DAV MX™ than ever before. Churchill is also seeing more of its CircSubs deployed in geothermal wells. Last year, the DAV MX™ was successfully deployed in the world’s deepest and hottest borehole, in Iceland, at a depth of 4,659m and 427º.

Churchill’s tools have the widest operating envelope in class. Supported by the company’s experience, customer performance, quality and capability, Churchill’s smart dart activated DAV MX™ is a multi-functioning, multi-cycling circulation sub that delivers significantly improved performance and is simple to use. Fast, versatile and reliable, it can be run in most environments and in a wide range of applications.

石油圈

石油圈