If there is a word that describes the U.S. energy industry, “resiliency”—the ability to spring back or rebound quickly—certainly comes to mind. Since early 2016 at one of the industry’s lowest points to today’s footprint, oil and gas professionals have figured out how to do more with less.

The industry’s never-give-up mindset that is shifting the country from a net energy importer to a net energy exporter by 2026 or earlier, according to the U.S. Energy Information Administration, is writing a new chapter in the industry’s history. This mindset is directed at producing a greater percentage of hydrocarbon using new methods that decrease geologic and financial risks in the greater efficiency scenario throughout the major U.S. shale plays.

As part of this scenario, a new, faster method of diversion design evaluation has been commercialized. DiverterSCAN technology offers near real-time evaluation to ensure hydraulic fracturing fluid stimulates multiple perforation clusters. LINN Energy, working in the Scoop/Stack, received the first near real-time results, increasing hydraulic fracturing efficiency.

Pressure-based fracture maps.

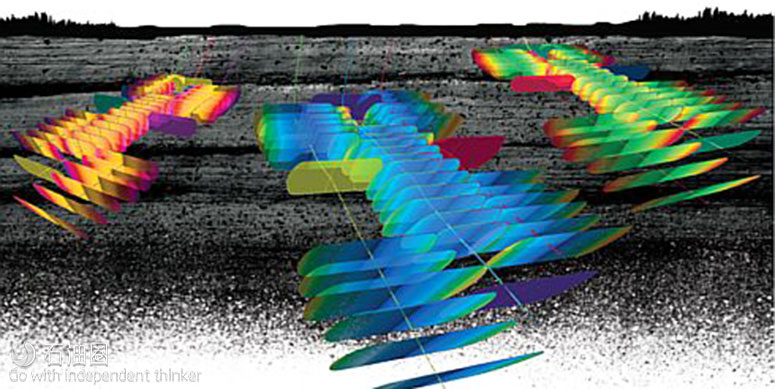

LINN Energy called on Reveal Energy Services, founded as a spin-out from Statoil Technology Invest in 2016, whose suite of five services is powered by pressure-based fracture maps. These fracture maps help operators better understand fracture geometry, proppant distribution, perforation clusters, depletion boundaries and diversion.

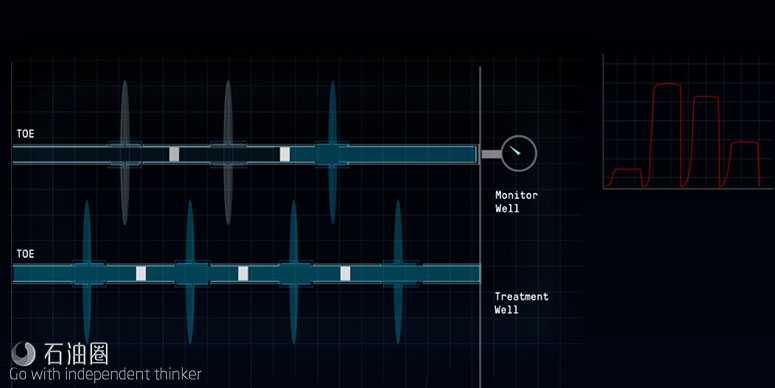

In this context, there is a treatment well that has been hydraulically fractured and is full of fluid, and an adjacent well, known as the monitor well, that has a pressure gauge placed at the wellhead. Because new fractures with the fluid leak-off generate a stress field pressure response in the monitor well, Reveal Energy Services was able to compute a pressure-based fracture map. The map is computed using a fully coupled 3-D model that compares the modeled pressure response with the observed pressure response in the monitor well.

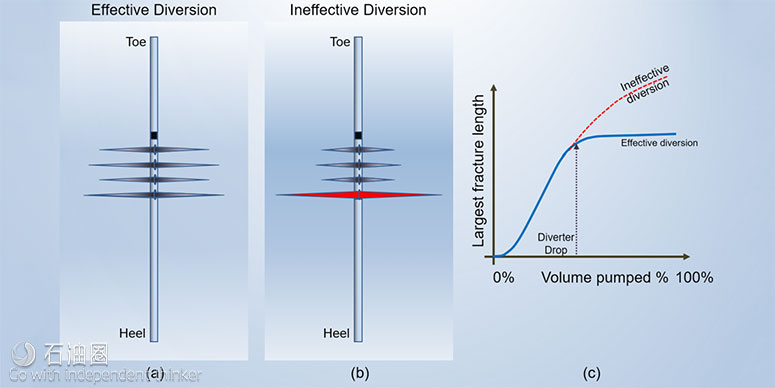

The operator was interested in quickly knowing what the maps would show about its diversion designs in the Scoop/Stack. Diverter material, which is typically a combination of chemicals, fibers and particles that create a temporary plug, diverts fluid from one cluster to another with the goal of improving the cluster effectiveness and the number and geometry of fractures created in a given stage.

Before hydraulic fracturing operations, a completion engineer designs the volume, rate, concentration and timing of the diverter drops. Because there is limited knowledge about fracture width and complexity, experience with the geographic area is vital. If the treatment does not enable adequate diversion, the engineer could iterate a different design. The iterative process, typically spread out over multiple wells or pads, could take a few months to determine the optimal design. This delay in identifying the optimal diversion design is the key reason Reveal Energy Services created DiverterSCAN technology.

“What is interesting is that with DiverterSCAN technology you can see the result of a correctly engineered diversion design by watching the fracture growth rate stop in near real time, providing the completion engineer with a tool to very quickly determine the success or failure of a given diversion design,” said Erica Coenen, vice president of operations and chief scientist at Reveal Energy Services.

Faster evaluation method

This new diversion diagnostic tool offers much faster diagnosis than several older methods that have been applied to monitor hydraulic fracture stimulations, such as temperature and production logging, radioactive tracers, borehole imaging, tiltmeter mapping and microseismic monitoring. Most of these methods, applied or analyzed after the stimulation operation, can take from several weeks to a few months to get the results.

DiverterSCAN technology looks at the growth rate of the largest fracture in the well using the pressure response measured in the offset monitor well as the treatment well is being fractured.

As shown in images (a) and (c) in Figure 1, a successful diverter drop results in stopping the growth of the largest fracture, while an unsuccessful diverter drop allows the largest, dominant fracture to continue growing, as shown in images (b) and (c) in Figure 1.

The purpose is for the diverter drop to force the fluid into all of the clusters to stimulate the entire stage. Unfortunately, in a typical stimulation treatment only 40% to 50% of the clusters are treated effectively and contribute to production. There is a significant opportunity to improve completion and cluster effectiveness.

LINN Energy was looking into testing several diversion designs and evaluating the effectiveness of each one for fieldwide implementation. Before LINN Energy began fracturing the well, Reveal Energy Services worked with the operator’s completion engineers to develop a comprehensive data acquisition plan that accounted for the planned fracturing sequence and any field operations constraints, such as zipper fracturing manifold and reach of overhead cranes. The data acquisition plan was included in the file operating guidelines. A real-time data stream was set up to transmit pumping data (pressure, rate and proppant concentration) and offset wellhead pressure to the Reveal Energy Services’ office.

Once fracturing had concluded on a given stage, an internal team of geoscientists and engineers completed the data processing and evaluated the effectiveness of individual diverter drops. The team communicated the results to the operator, usually within 2 hours of completing a stage. Valuable insight was obtained on specific diversion techniques that were successful in stopping growth of the largest fracture. Using these results, the operator adjusted and modified the diversion scheme for the subsequent wells and pads completed in that area.

“Within 2 hours, we received analysis that allowed us to evaluate the effectiveness of our diversion implementation while completing wells on one of our Stack/Scoop pads,” Byron Cottingham, senior engineer for LINN Energy, said. “With these quick results, we determined the most effective diversion design on the remaining stages, instead of relying on one unverified design for the entire completion.”

Conclusion

An intrastage diversion design is applicable to almost every multistage or multiperforation completion. The right design supports greater cluster efficiency with a more robust fracture network that has greater access points to the wellbore.

石油圈

石油圈