Advanced stabilization conical element cutter block

The StingBlock* advanced stabilization conical element cutter block improves footage and ROP in challenging drilling applications that pose a high risk of vibration to the BHA and impact damage to conventional cutter blocks. This unique-geometry cutter block features a staged gauge pad for increased stability and Stinger conical diamond elements for enhanced impact resistance. Field tests have demonstrated up to a 29% increase in ROP and a 56% increase in footage compared with benchmark results in the Gulf of Mexico.

APPLICATIONS

Challenging drilling applications

Medium- to high-strength formations

Conditions with a high risk of vibration and excessive damage to the cutter block

BENEFITS

Improved footage and ROP for increased drilling efficiency

Enhanced stability for improved BHA durability

Increased point loading to better fracture hard-to-drill formations

FEATURES

Staged gauge pad reduces lateral displacement and improves stability

Stinger* conical diamond elements provide a significantly increased point load on the rock for increased impact resistance

Nonlinear cutter alignment disrupts drilling harmonics and increases efficiency

Compatibility with all Rhino integrated borehole enlargement systems improves operational flexibility

Enhanced stability for shock and vibration mitigation

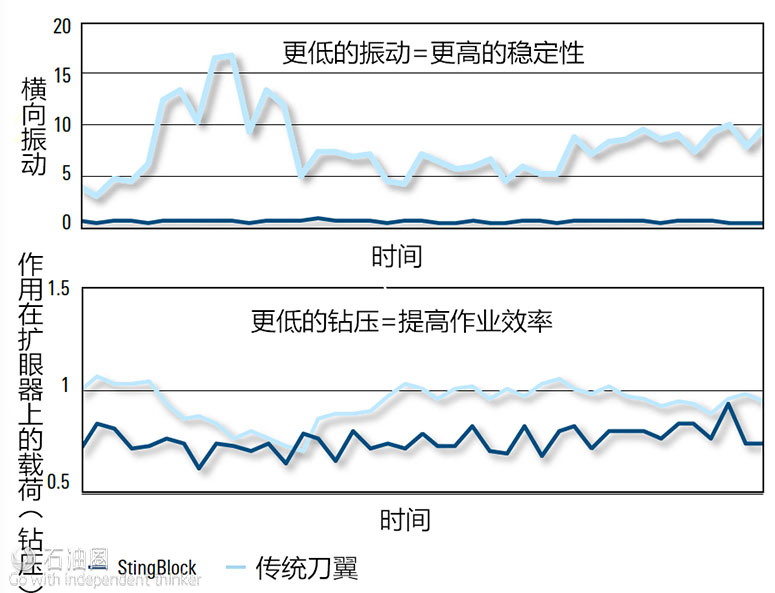

In high-impact and challenging applications, cutter blocks with a single gauge pad lack the necessary stabilization when encountering hard and interbedded formations. The increased area of the main gauge pad, coupled with the additional staged gauge pads, uniformly distributes the cutter block forces, enabling significantly enhanced stability with lower lateral displacement. During testing of multiple cutter block sizes in different formations, finite element analysis simulation studies show an average of 65% less lateral vibration compared with standard blocks. Full-scale drilling tests demonstrated an average reduction of 83% in lateral vibrations.

Increased durability for maximum ROP and longer runs

The Stinger element has a diamond layer twice as thick as that of a conventional PDC cutter for enhanced impact strength and cutter durability. Its unique geometry extends runs and increases ROP by creating an ultrahigh-concentrated force that fractures high-compressive-strength rock more efficiently. Additionally, the advanced stabilization from the staged gauge pad reduces vibration and enables longer runs with the StingBlock cutter block as well as prolongs the operating life of the underreamer and other BHA components.

Improved drilling efficiency in a wider range of operating parameters

The nonlinear cutter alignment disrupts drilling harmonics so that more energy is applied to drilling ahead instead of being lost to vibrations. Full-scale drilling tests show that the StingBlock cutter block requires 24% less weight on reamer compared with conventional cutter blocks, enabling a wider range of operating parameters.

The Gould Research Center in Cambridge designed a full-scale test to compare underreaming operations of two Rhino systems. In this test, one would be equipped with conventional cutter blocks and the other one fitted with StingBlock cutter blocks. The test assessed performance while enlarging an 8½-in pilot hole to 10¼ in.

Results of the full-scale lab test simulated underreaming operations in a hard limestone formation. The parameters were controlled with an ROP of 60 ft/h and 160 rpm. The measured results showed that the StingBlock cutter block reduced lateral vibration levels by 94% while requiring 24% less weight on the reamer, indicating overall improved drilling efficiency.

石油圈

石油圈