Wild Well’s WellCONTAINED subsea solutions offer strategically positioned deepwater containment systems for immediate deployment, along with access to key personnel whose primary function is delivering emergency engineering for offshore operations. The department is supported by risk management, advanced engineering and well control personnel.

The service offers the industry unique subsea containment solutions for global deepwater well control incident prevention and response. The wholly in-house approach assists operators with prevention, preparation, response and recovery operations.

Containment systems with a global reach. Having positioned capping stacks in Aberdeen and Singapore, the company has the ability to access key locations in the North Sea, Southeast Asia, West Africa and Australia through these logistical hubs. The subsea containment systems, therefore, provide global coverage for deepwater operational hotspots in the Eastern and Western hemispheres. The kit’s modular design facilitates quick global deployment on readily available cargo aircraft, including the Boeing 747 and An‐124.

FOUR MAIN COMPONENTS

Subsea capping stack. The company’s subsea capping stacks provide a unique function that is effective when the deployment is managed by the WellCONTAINED team. A capping stack is designed to either shut off or divert flow from a well. However, it cannot be used as a workover BOP, because it is designed with blind rams, and such use would add operational complexity and increase the potential for failures in a well control operation. If concerns about damage to the tubulars or wellhead system exclude shutting off the flow because of pressure buildup, then the capping stack can be used to divert flow to capture effluent to reduce water pollution while a relief well is drilled.

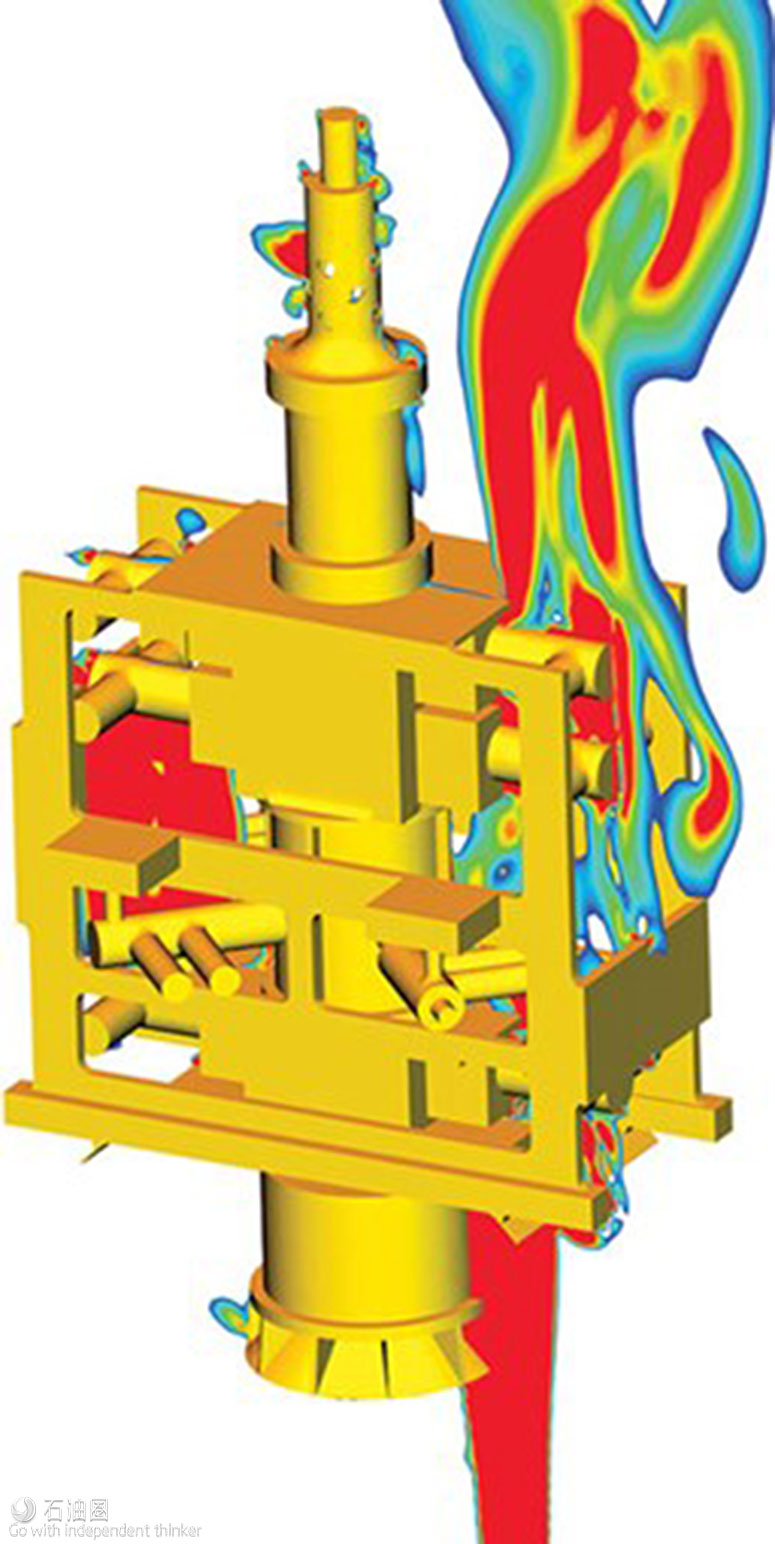

Design criteria for the capping stack include a depth rating to 12,500 fsw, 15,000-psi shut‐in pressure, dual mechanical barriers and the ability for ROV control of all functions. The stack uses 18?-in., 15K Cameron TL ram assemblies and a drilling spool with four 3 1/16-in. outlets. This facilitates the installation of chokes for soft shut‐in operations or gooseneck assemblies for extended flow-back/well-kill operations. It can be connected to a BOP, flex joint or on top of a wellhead. The stack is deployable on drill pipe or wire, and deployment is aided by a rig or a crane/winch wire. The system features chemical injection (dispersant or hydrate mitigation/remediation) and internal pressure and temperature monitoring capabilities with acoustic transmission of readings to the surface.

A subsea dispersant package includes all hardware to facilitate the application of dispersants, subsea, from the client-provided coiled tubing unit through application wands or ROV hot stabs. Key components include the coiled tubing routing manifold, subsea distribution manifold and subsea hose deployment reel, with 1,000 ft of various-length 1-in. application and routing hose. The system is rated to 10,000 psi, and may also be used to convey hydrate inhibition and remediation chemicals, as well as control line fluids.

The debris removal package contains two sizes of subsea shears that can cut tubular and structural members up to 46 in.. The shears can be used for activities like cutting bent or broken riser, shearing pipe, or clearing an area to prepare for capping stack activities. In addition to the shears, ROV utility cutting tools, such as the Super Grinder, are part of the kit, and would be used for light debris removal and site preparation for the capping stack installation.

Subsea hydraulic power to the equipment employed during the response operations is provided, utilizing ROV-deployable hydraulic skids. One, each, of these skids is located in each kit to ensure fast deployment in case of incident. This tooling may also be used to conduct secondary operation of the primary BOP.

COMPREHENSIVE ORGANIZATION STRUCTURE

Assembling a team of competent problem-solvers, who can communicate effectively with multiple parties and integrate into an external organizational structure during time-critical well control events, can be difficult. The company has more than 40 years of well control experience, along with a team of experienced specialists and engineering personnel. This comprehensive in-house well engineering workforce effectively fills the gaps in organization response structures.

The WellCONTAINED subject matter experts have worked side-by-side with incident management and source control response teams. They have been involved in some of the largest, most challenging emergencies, working with teams at the state, federal and international levels.

Using advanced equipment and engineering expertise, well control incidents can be mitigated further by developing risk management programs that identify and analyze well control risks associated with different activities throughout the life of a well. The success of this program requires a commitment of continuous implementation. The company provides several services that address well control risks during the planning phase of a well design, and are outlined below.

The Risk Management Services (RMS) group offers source control emergency response planning, training and drills to better prepare operators for the most-challenging deepwater operations. Pre-event well control planning benefits operations in several ways, and is an excellent way to organize personnel and contractors in the event of a major well control incident. It is also a way to inform key personnel of the material and equipment requirements that may be needed for a well control job.

Ultimately, this level of emergency preparedness saves time, money and, most importantly, lives, in the event of a well control incident. The company has the experience and technical expertise to write an effective emergency response plan. For floating operations, planning includes development of source control emergency response plans to support field deployment of a containment system for capping an uncontrolled subsea well.

RMS provides offshore operators a comprehensive solution to their contingency planning and response requirements. Working through a well-defined series of activities helps to ensure that critical aspects of the response are given adequate consideration, and that proper safety and operational assessments are made at the required time. Overall, measures are taken to improve the coordination, integration and interaction of a business or organization’s policies, procedures, roles and responsibilities before, during, or after simulated events.

The company also offers an Advanced Subsea Well Control training course designed by engineers, for engineers in well control situations. The instruction helps personnel avoid common miss-steps in the initial dealings during subsea well control events that lead to prolonged and unnecessary downtime. The training can prevent days or weeks of downtime, and potentially save the wellbore and sidetrack operations. The course is instructed by senior engineers/first responders with both field and office-based experience.

The development of the course enables Wild Well to use a methodological discovery process to improve critical thinking and problem-solving skills.

Real-world scenarios selected from the company’s archives are used in a realistic team-based approach to help students develop the technical and nontechnical skills essential for improving drilling and safety performance. The course encourages participation among the different levels of decision-makers from multiple companies. Constructive discussion is encouraged, as participants examine and resolve problems, based on existing operational plans and identify where those plans need to be modified. The team-based training enhances situational awareness, communication, leadership, and decision-making skills. Given the complexity of a subsea operation, this course is ideal for personnel with a minimum of 10 years upstream drilling and completions experience, with five in deepwater drilling operations.

CFD/FEA capabilities

The company’s advanced engineering department offers state-of-the-art, computer-aided engineering, computational fluid dynamics, and finite element analysis capabilities that include:

1.Atmospheric dispersion and radiant heat analysis;

2.Erosion analysis;

3.Flow assurance;

4.Multi-phase flow;

5.Subsea plume analysis;

6.Fire explosion blast analysis;

7.Structural analysis.

Utilizing CFD enables the department to simulate a subsea hydrocarbon release. Wild Well is the only well control company to have its own CFD capabilities developed over the last decade. CFD can be applied to any blowout scenario, whether the release is natural gas, oil, or a combination of both. It can be applied at any water depth and/or flowrate. With a subsea blowout comes the added complication of knowing where the gas will surface and determining the rate. CFD can track and predict the likely extent of a gas cloud caused by a blowout or leak. The company has been part of a JIP investigating subsea underwater releases, which has used large-scale experiments to develop improved CFD models to more accurately predict subsea plume behavior.

Use of advanced engineering methods, such as atmospheric gas dispersion and radiant heat studies, can provide a substantial benefit in the planning phases and enables the company to develop source control plans that can accommodate any situation.

Additionally, relief well planning is based upon an engineered procedure requiring several iterations to arrive at an optimum plan. There are key success factors associated with developing an effective floating relief well plan, such as:

1.Have good diagnostic, strategic and tactical plans;

2.Plan to milestones; always have a backup plan;

3.Never execute a plan that eliminates alternatives.

Developing a relief well contingency, as a planning exercise, requires the development of realistic blowout scenarios. This can be done by either performing a detailed risk assessment of the drilling and well design program, or assuming a blowout has occurred under a defined set of circumstances. Typically, worst-case scenarios are developed to define constraints and resource requirements, and to identify gaps in available resources, technology and logistics. In most cases, this approach can adequately identify deficiencies, weaknesses and critical issues. Some of the typical required information includes:

1.Well mechanical configuration and trajectory;

2.Blowout flowpath and exit conditions;

3.Blowout fluid(s) composition, physical and PVT properties;

4.Reservoir parameters for flowing zones;

5.Pore pressure, temperature and fracture gradient curves from seabed to total depth.

CONCLUSION

Successful deepwater source control emergencies rely on a wide range of services, equipment, and efficiently trained personnel. Essentially, the philosophy of WellCONTAINED has always been to provide the best coverage and tactical support for all subsea well control response needs, from the quality and scope of the complete subsea capping package, to the maintenance and logistics support that is fully integrated in the approach. The company offers a “one-stop shop,” with the subsea containment solutions system and the experienced personnel that provide the intelligent planning and innovative solutions behind the operation.

石油圈

石油圈