AI Database Saves Logging Time

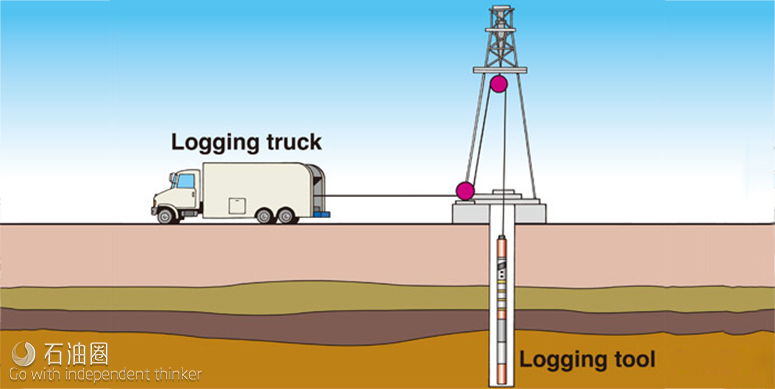

As wells become more complex, logging and LWD measurements become more challenging to obtain. Quantico Energy Solutions provides a cost-effective alternative to LWD or through-drillstring logging tools in horizontal wells. The company recently developed QDrill, a proprietary artificial intelligence (AI) software that provides petrophysical properties of a reservoir, including LWD and wireline logs. As input, the algorithm uses gamma ray logs and drilling dynamics data (ROP, weight on bit, torque, etc.) for many domestic and international basins. QDrill was developed using a proprietary database of several hundred wells that have the measured well logs plus the drilling data. This large database of logs and formation data provides unique capability to provide reservoir properties without running expensive logging tools.

One operator was initiating a horizontal drilling project in the Midcontinent region of the U.S. It targeted a formation with a traditional clastic laminated/layered sandstone reservoir. A “blind test” was arranged with data from nearby vertical and horizontal wells to train the AI model for this project.

Results were significant—the operator increased operational effectiveness by using logs from Quantico on a daily basis while drilling two laterals. These logs were used in timely geosteering interpretations for targeted placement of completion stages in higher porosity intervals. They also enabled completion stage/perforation cluster placement to equalize minimum horizontal stress across the stage at each of the perforation clusters. Additionally, the logs aided drilling decisions in unexpected ways. For instance, a worn bit was pulled close to planned total depth (TD) in one of the wells; rather than terminate the well, favorable porosity seen toward the end of the lateral in the Quantico log convinced the operator to go back in hole and drill to TD. No LWD logging tools were required, and therefore the operator was able to save costs on nonproductive time and running of the LWD tools.

Accuracy and repeatability

Quantico’s database of existing well logs, encompassing hundreds of horizontal wells from both conventional and unconventional reservoirs, indicated that in typical conditions the repeatability of through-drillstring logging tools was 2% to 3% for density and 5% to 6% for sonic. The AI models constructed for this formation performed within the expected parameters as demonstrated by blind tests conducted by the operator.

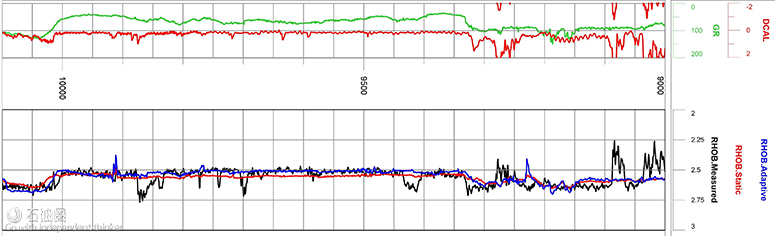

To ascertain predicative accuracy and repeatability of the AI-driven logs vs. actual logging with associated tools costs, a static and an adaptive model were used. The difference between results in these two models showed the variability in the QDrill logs. The static model employed a combination of the proprietary database and local data previously collected by the operator before the project. As additional through-drillstring logs were acquired (with logging tools), the adaptive model added the logs into the training set for the AI models.

The figure illustrates the minor differences in the bulk density from the static and adaptive models compared to the measured bulk density from the through-drillstring logging tool. A shift in the centroid of the density error from 0.017 grams/cubic centimeter (gm/cc) to -0.003 gm/cc was observed. These differences are much less than the precision or repeatability of the density logging tool. In addition, the operator noted that the QDrill logs performed better as compared to the errors in the logging tool response caused by hole washout conditions, which adversely affects the density tool’s pad contact with the formation.

Putting the density variance of 0.017 gm/cc to -0.003 gm/cc into porosity resulted in an uncertainty window of 0.012 porosity units, which is well within the acceptable range.

Value

Quantico provided the operator with critical formation data for these horizontal wells that would have been cost-prohibitive had it logged the well using conventional methods. Assuming general costs for the through-drillstring tool of $150,000 per lateral, the savings delivered to the operator on data acquisitions costs was more than 80% using QDrill.

Additionally, while the conventional logs were used for qualification of the technology, the project also gave the operator a framework for planning its data acquisition program using conventional logging tools. In this instance, it was demonstrated that logging three additional wells for $450,000 merely reduced the uncertainty of the AI models by less than the precision of measurement of the through-drillstring logging tool. The accuracy and repeatability of QDrill was validated by a series of three blind tests. This project also provided the operator with the empirical context to determine when conventional logging tools would be run in the future vs. using the AI technology for the vast majority of the wells in the area and, in instances of the former, what the costs vs. benefit would be.

The AI-based logging data were delivered to the operator on a daily basis to assist with geosteering, drilling and completion decisions while drilling operations were ongoing.

This service has been qualified with several major operators on both U.S. land and deep water. By leveraging AI with the proprietary database, QDrill provides a game-changing way to increase reservoir understanding at a fraction of traditional logging costs and without the associated risks of running downhole tools.

石油圈

石油圈