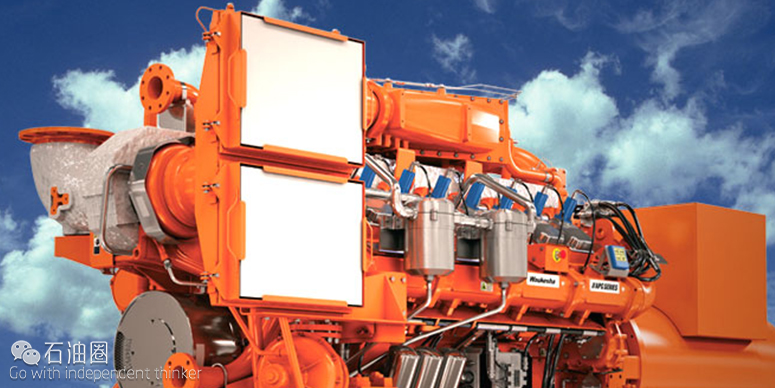

DALLAS—October 28, 2015—GE’s Distributed Power business today announced the introduction of its new Waukesha* VGF* high-speed gas engine models that, for the first time, combine the company’s proven compact gas engine design with advanced controls normally used in GE’s larger Waukesha units.

Offering advanced controls and aftertreatment capabilities as standard features, the VGF units give operators greater flexibility for on-site power, air/gas compression and drilling applications for oil and gas production compared to other engines available in the 300-600 horsepower high-speed range.

The VGF is adapting the controls and emissions reduction technologies from GE’s larger Waukesha VHP engine, the industry workhorse for gas compression and oilfield power generation. Previously used only for stationary applications before the upgrades, the new F18SE and H24SE VGF models will be available with EPA non-road (mobile) certification for air quality, allowing the units to also be deployed for mobile applications. The certification on the engine also includes coverage for certain stationary applications.

- GE Offers VGF Units with Advanced Controls as Standard Feature for Compact Horsepower Segment, Giving Operators Greater Emissions Reduction and Other Capabilities

- Advanced Controls Enhance Operator Ability to Reduce Engine Emissions during Gas Compression, Mechanical Drive and On-Site Power for Oil and Gas Production

- New Units Extend Maintenance Intervals and Lower Operating Expenses

“Our new Waukesha VGF gas engines from GE offer greater flexibility and added value for operators to deploy our engines in difficult applications and high altitudes,” said Wouter-Jan van der Wurff, general manager for gas engines up to 2 megawatts (MW) for GE’s Distributed Power business.

Until now, engine packagers would buy the engine from GE or another supplier and then the three-way catalyst and air-fuel ratio control systems from other suppliers. But with the introduction of GE’s new Waukesha VGF models with the emPact product offering, GE is offering packagers and end users a more beneficial “one-stop shop“ for the gas engine, controls and aftertreatment systems.

In addition to the advanced controls, GE’s two new Waukesha VGF models offer improved oil filtration for a healthier engine as well as improved oil cooling capabilities, allowing the unit to operate in even hotter ambient conditions. Additional enhancements include extending the life cycle of the cylinder heads, a new closed crankcase breathing system and a new high-altitude turbocharger coupled with a water-cooled wastegate. These engine improvements also will be offered to operators of existing VGF units in the field.

The new VGF models‘ top-end maintenance intervals have been extended 36 percent, which is a significant upgrade over the existing GSI engine and a 50 percent longer interval than competing engines. The major overhaul interval also is twice as long as offered by other engines. Longer intervals translate into less downtime and higher package availability. Finally, when it comes to servicing the internal components, the VGF is the only engine in its class that offers full access at the job site. The units also will operate for 1,500 hours without an oil, filter and spark plug change, compared to 720 hours required by other engines. This is a key advantage over existing systems because it meets or exceeds EPA NESHAP maintenance guidelines.

The new VGF F18SE and H24SE engines with advanced controls already have been deployed for a half dozen successful U.S. demonstration projects to prove their advantages over existing engines, including projects in stationary gas compression and power generation as well as mobile power generation and air/gas compression.

The new engines will be commercially available in the first quarter of 2016. The new units were announced during the 2015 High Horsepower (HHP) Summit at the Kay Bailey Hutchison Convention Center in Dallas. For more information, please visit GE’s booth #531.

Total Fuel Flexibility:Waukesha engines are capable of operating on a wide range of fuels, from 400 to 2,350 BTU/sq.ft., making them work well for a variety of applications.

The World Chooses Waukesha:With excellent tolerance for variable fuel quality that increases output, uptime, and profitability, Waukesha engines are used worldwide.

Designed from the Inside Out:The VGF series of engines is built to deliver continuous output, with industrial strength to handle continuous high rpm up to 1,175 HP (876 kWb).

PRODUCT SPECIFICATIONS

Durable, Compact, and Fuel-Flexible VGF engines have a power output of 120 kW to 800 kW (265 bhp to 1,175 bhp).

Built to perform reliably in mission-critical and demanding oil and gas applications:

With more than a century of innovation and engine-building expertise, Waukesha gas engines are designed and built to perform reliably in isolated, mission-critical, demanding applications in oil and gas fi elds the world over.

Waukesha natural gas-fi red engines drive compressors and electrical generators featuring extended maintenance intervals, fuel fl exibility, and rich-burn, lean-burn alternatives for optimal fuel effi ciency at varying emissions compliance levels.

– Able to keep running on varying fuel quality

-More power at high altitudes/ambients

– Both rich-burn and lean-burn models available to better match project requirements

– Extended oil change intervals

– Longer periods between servicing

- Simple controls and communications

石油圈

石油圈