本文将讨论新型耐盐减阻剂体系在Marcellus页岩的现场试验。

来自 | JPT

编译 | 白小明 影子

无论是用于滑溜水压裂还是连续油管增产,减阻剂都可提高泵送水排量,同时维持较低的处理压力。通常而言,常规丙烯酰胺/丙烯酸共聚物或部分水解的聚丙烯酰胺基FR的性能随着源水的溶解离子含量增加而减小,并且还取决于源水中的离子类型和浓度。基于此限制,用于滑溜水压裂作业的返排水和产出水通常需要用淡水来稀释以保持足够的减阻性能。为了100%利用产出水,已开发的新型减阻剂可让总溶解固体含量(TDS)超过300,000ppm的返排水和产出水得到近乎淡水的性能。

新型耐盐减阻剂(FR)体系设计用于特定的高盐度范围,可在滑溜水水力压裂应用中100%利用返排水和产出水,无需用淡水进行稀释。耐盐FR服务可用于TDS大于300,000ppm的情形;其在不同溶解盐离子的水中有效,这些离子包括氯化物、硫酸盐、钠、钙和镁;它还能适用于各种未知的、可能会使传统的FR失效的污染物。低浓度(0.25~1加仑/1,000加仑)的新型FR体系在粘土控制盐水、返排水和产出水中仍可起作用。

这种新型耐盐减阻剂体系包含一种油包水阳离子聚合物和反相剂。与其他FR不同,新型减阻剂的独特优势在于,聚合物与反相剂的比例可以随时进行调整,以最大程度减小摩阻。在泵送作业期间,反相剂被证实能够迅速将聚合物从油中释放到水中实现相反转,并且阳离子聚合物即使在污染严重的水中,也能非常有效地减少多余的套管摩阻。此外,使用单一的FR可减少产品库存,简化现场材料使用的质量控制。

流动回路测试

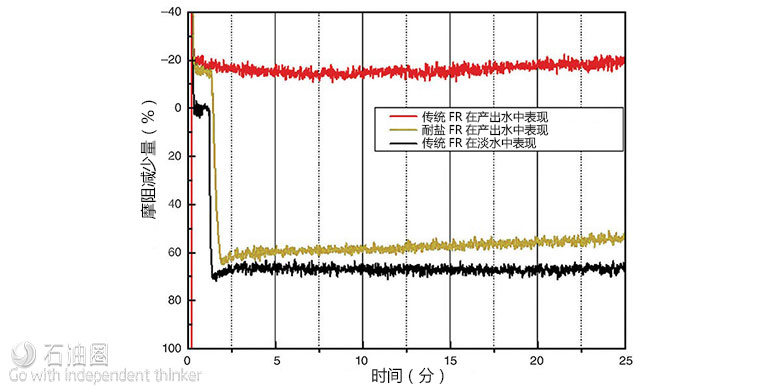

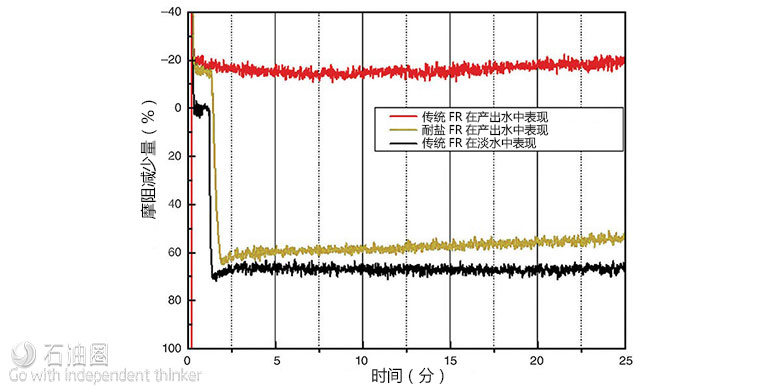

图1.新型FR在总溶解固体含量为200,000ppm的水中表现优于传统的FR。

通常,在实验室进行摩阻回路测试来确定各种FR的性能。该测试能够显示FR在处理或源水中的减阻情况,这将最终影响处理压力和增产处理期间对液压水马力的要求。然后将这些数据与传统FR在淡水中的数据进行比较,得出结论。图1显示了新型耐盐FR的性能。与传统的FR相比,对现场供水水源,新型耐盐FR表现出更优越的性能。这些结果表明,耐盐减阻剂能够在压裂作业中使用无需稀释的返排液和产出水,从而减少了(用于稀释的)水的额外开支和物流成本,这些水最终将被视为废弃物而进行处理。此外,使用这种化学液体能够重复使用返排液和产出水,这将是经济、环境可持续的解决方案。

在现场实际泵送过程中,管道的减阻效果受FR载荷、FR有效性,以及FR在压裂液中的分散性等多个参数影响。特别是FR的化学性质非常重要。最常用的阴离子FR,如部分水解的聚丙烯酰胺,倾向于在高含TDS的水(如TDS大于60,000ppm的水)中聚集结块、无法完全伸展,这将使减阻效果变差。然而,阳离子减阻剂可以克服这一难题,因为它们受阳离子(与压裂液中的TDS含量直接相关)的影响较小。换句话说,它们仍然可以在一定程度上伸展和延伸。

现场试验

通常,作业人员会以较高的排量泵送滑溜水体系以覆盖压裂设计指定的岩石范围。当FR在平均处理排量(ATR)、平均处理压力(ATP)下不能充分减阻时,通常会提高FR浓度。与常规FR相比,这种耐盐阳离子减阻体系无需提高浓度,可采用较低的处理压力和泵送排量。作业人员在Marcellus页岩进行了三口井的现场试验。

1号井,压裂前10段采用传统的FR,之后采用耐盐FR。ATP和ATR立即作出响应,ATR基本维持在大于90桶/分钟的水平。在第20段作业期间,ATR下降到90bbl / min以下,这是由于操作人员在作业中调整了耐盐FR和反相剂的比例。

2号井,前14段泵入现场标准的阴离子减阻剂。ATP维持较高水平,并在8,700和9,100 psi之间波动。当从第15段压裂开始,切换为耐盐FR后,ATP立即下降到8,100psi,并保持在8,000~8,700psi之间,波动主要是由于在作业中调整FR和反相剂比例造成的。另外,ATR在转换成耐盐FR后即刻增至100桶/分钟,并在其余各段保持了这一排量。

如果把常规减阻剂和耐盐减阻剂体系的ATP看作是受污染水重量百分比的函数,那么数据表明耐盐减阻剂即使在水100%受污染的情况下,仍能保持相对较低的处理压力(小于9,000psi)。对ATR而言,数据充分表明,即时针对100%的受污染水,与现场标准FR相比,耐盐FR体系也能够将处理排量提高至100桶/分钟。

通过对比各段常规FR和耐盐FR体系的浓度,结果表明耐盐FR即使浓度低于1加仑/ 1,000加仑,仍能能保持较高的泵送排量。

结论

在滑溜水压裂作业中,作业人员配制并泵送了一种耐盐减阻剂,100%利用了产出水。与常规FR相比,ATP维持在较低水平,ATR维持在较高水平。此外,在大多数泵送阶段,耐盐FR浓度保持在1加仑/ 1000加仑以下。通过调整反相剂的用量,耐盐减阻剂体系可根据需求进行定制,这提高了100%使用产出水应用环境下的减阻效果。

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

二丫:131-3255-0596;zhanglingyu@raiborn.com

大安:131-3203-1392;lishian@raiborn.com

For English, Please click here (展开/收缩)

To continue to treat multiple clusters in longer laterals effectively, even for stages near the toe, a robust friction-reducer (FR) system typically is required to overcome pipe friction. Additionally, using a single FR system throughout the entire treatment that can tolerate various water sources of varying salinity up to 300,000 ppm is imperative. This paper discusses the field trials of a new salt-tolerant FR system in the Marcellus Shale.

Introduction

FRs are used to enable high-rate pumping of water while maintaining lower treating pressures in both slickwater fracturing and coiled-tubing stimulation applications. Typically, the performance of conventional acrylamide/acrylic acid copolymer or partially hydrolyzed polyacrylamide-based FRs diminishes as the dissolved-ion content of the source water increases and can be dependent on both the type and the concentration of ions present in the source water. Because of this limitation, flowback and produced water used for slickwater applications are often diluted with a freshwater source to maintain adequate friction-reducing performance. To enable the use of 100% produced water, new friction reducers have been developed that are capable of providing near-freshwater performance in flowback and produced water exceeding 300,000 ppm total dissolved solids (TDS).

The new salt-tolerant FR consists of FR systems that are designed to work in a specific range of high salinity to enable the use of 100% flowback and produced water in slickwater hydraulic-fracturing applications without requiring dilution with fresh water. The salt-tolerant FR service can handle TDS levels greater than 300,000 ppm; is effective in water containing a variety of dissolved salt ions, including chlorides, sulfates, sodium, calcium, and magnesium; and can tolerate a variety of unknown contaminants that might render conventional FRs ineffective. The new FR system is effective at low concentrations (0.25 to 1 gal/1,000 gal) in clay-control brines and flowback and produced-water sources.

This new salt-tolerant FR system consists of a water-in-oil cationic polymer and an inverter. Unlike other FRs, the distinctive advantage of the new FR is that the ratio of polymer to inverter can be readily adjusted on the fly to achieve maximum friction reduction. During the pumping operations, it was demonstrated that the inverter was sufficiently quick to invert and release the polymer from oil to water and the cationic polymer was extremely efficient at reducing additional pipe friction, even with severely impaired water. Additionally, the use of a single FR reduces inventory stock and simplifies on-location quality assurance of material usage.

Flow-Loop Tests

Laboratory friction loop testing is typically conducted to determine the performance of various FRs. This testing provides an indication of the friction reduction of the FR in the treatment or source water, which ultimately will affect treating pressures and the hydraulic-horsepower requirements during a stimulation treatment. These data can then be compared with those from conventional FRs in fresh water, and a conclusion can be drawn. Fig. 1 above displays the performance of the new salt-tolerant FR. The new salt-tolerant FR displayed superior performance in field-supplied water sources compared with the conventional FR. These results show that salt-tolerant FRs enable the use of undiluted flowback and produced water in fracturing operations, consequently reducing the need for excess expenses and logistics for water that otherwise would be considered waste stream for disposal. In addition, the use of this fluid chemistry enables recycling of flowback and produced water, which can be economically and environmentally sustainable solutions.

During actual pumping on location, the pipe friction reduction is affected by several parameters, such as FR loading, FR effectiveness, and how well the FR is dispersed in the fracturing fluid. In particular, the chemistry of the FR is crucial. Most commonly used anionic FRs, such as partially hydrolyzed polyacrylamides, tend to agglomerate and do not stretch fully in high-TDS water (e.g., water with greater than 60,000 ppm TDS), which results in poor friction reduction. Cationic FRs, however, can overcome this challenge because they are less affected by the presence of cations, which directly correlates to the TDS level in the fracturing fluids. In other words, they can still stretch and extend to some extent.

Field Trials

A slickwater system is typically pumped at higher rates to cover the rock volume as specified in the fracture design. When the FR does not provide sufficient reduction in the average treating pressure (ATP) at the average treating rate (ATR), the FR concentration is usually increased. This salt-tolerant cationic FR system does not require increasing the concentration yet allows lower treating pressures and pumping rates compared with conventional FRs. A three-well trial was executed in the Marcellus Shale.

For Well 1, the conventional FR was pumped for the first 10 stages, after which the FR was switched to the salt–tolerant FR. Both the ATP and the ATR immediately responded, and an ATR greater than 90 bbl/min was largely maintained. During the 20th stage, the ATR dipped below 90 bbl/min, which is attributed to the operator adjusting the ratios between the salt-tolerant FR and the inverter on the fly.

For Well 2, the field-standard anionic FR was pumped for the first 14 stages. The ATP remained high and fluctuated between 8,700 and 9,100 psi. As soon as the conventional FR was switched to the salt-tolerant FR at the 15th stage, the ATP immediately dropped to 8,100 psi and remained between 8,000 and 8,700 psi, with the fluctuations resulting from the ratios between the FR and the inverter being adjusted on the fly. In addition, the ATR increased to 100 bbl/min -immediately after the switch and was maintained at that rate for the remaining stages.

When looking at the ATP for both the conventional FR and the salt-tolerant FR system as a function of the weight percentage of impaired water, the data illustrate that the salt-tolerant FR was able to maintain relatively low treating pressure (less than 9,000 psi) at 100% impaired water. In terms of the ATR, the data strongly suggest that the salt-tolerant FR system was able to raise the treating rate to 100 bbl/min compared with the field-standard FR, despite the use of 100% impaired water.

Comparing the FR concentrations at each stage for the conventional and salt-tolerant FR systems, the salt-tolerant FR generally maintained a higher pumping rate, even at a concentration lower than 1 gal/1,000 gal.

Conclusions

A salt-tolerant FR system was formulated and pumped in slickwater fracturing treatments with up to 100% produced water. The ATP was maintained lower and the ATR was maintained higher compared with those observed with the conventional FR. Furthermore, the salt-tolerant-FR concentrations, for most of the pumped stages, were maintained below 1 gal/1,000 gal. The salt-tolerant FR system is customizable through independent inverter dosage, which results in improved friction-reduction performance for use in 100%-produced-water conditions.

未经允许,不得转载本站任何文章:

石油圈

石油圈