Adaptable technology and expert engineering provide new answers for integrating riser gas handling capabilities on floating rigs.

AFGlobal’s next-generation Riser Gas Handling (RGH) system features a unique, purpose-built design that offers the simplicity, flexibility, and reliability required to efficiently mitigate gas for dynamically positioned and moored rigs. Our industry-leading expertise ensures full integration with your rig system and operations.

Integral to the drilling riser, the highly adaptable RGH system provides solutions for retrofit and newbuild applications using specialty riser joints and equipment.

Advanced AFGlobal RGH systems are transparent to rig processes. Operations move seamlessly and efficiently from conventional drilling to RGH mode. And when you are ready, our flexible RGH systems are uniquely designed to provide an easy transition to third-party managed pressure drilling (MPD).

In a competitive marketplace where safety and efficiency are critical, Our RGH systems provide a reliable, flexible solution for adding riser gas handling and MPD capabilities to your drilling system. The RGH system provides:

– Full integration with rig and riser

– Adaptable technology adaptable

– Experienced engineering

– Seamless operation

– Ready for MPD design

CLOSED-LOOP ADVANTAGES

The RGH system equips floating rigs with the ability to mitigate riser gas, and easily apply MPD to overcome extreme drilling conditions. Both RGH and MPD are based on creating a closed-loop drilling (CLD) system. Instead of a conventional circulating path that is open to the atmosphere, CLD diverts annular flow from the wellbore and ultimately diverts flow away from the rig floor.

The RGH system closes the loop with a hydraulically activated packing element housed in a specialized riser joint. The element is quickly closed around the drill pipe for annular diversion or opened for conventional drilling operations. The closed packing element diverts return flow through the RGH flow spool and armored hoses to the rig choke manifold or distribution (buffer) manifold for handling.

A CLD system is also a prerequisite to applying MPD methods. MPD service providers create a CLD system on a floating rig by diverting annular wellbore flow using a rotating control device (RCD) installed in the riser. The AFGlobal RGH system uniquely enables the addition of the service provider’s RCD with a specialized adapter joint that integrates it with the riser.

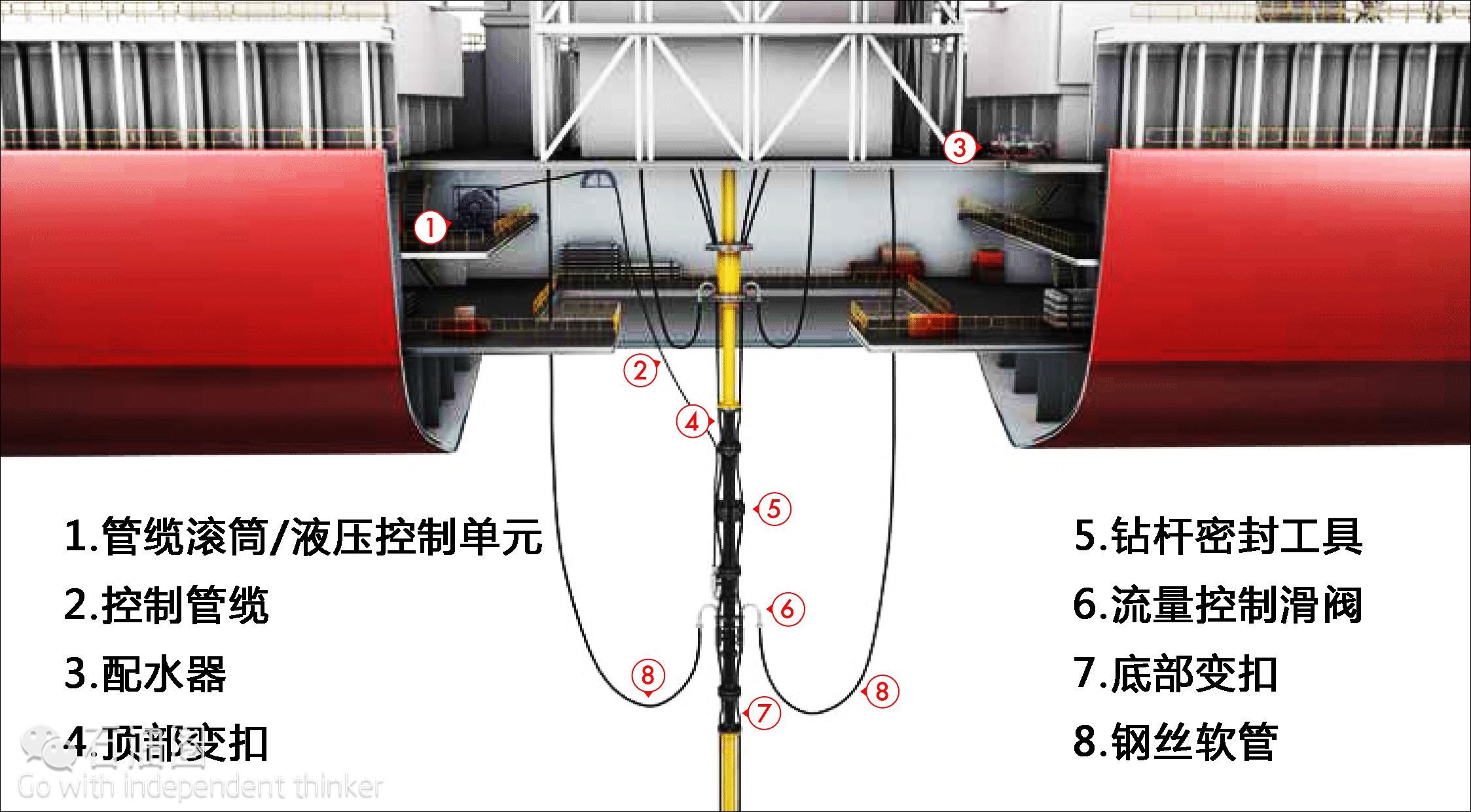

INTEGRATED RISER GAS HANDLING SYSTEM

The RGH system is a versatile technology that can be easily adapted to specific drillship and operational requirements. RGH assemblies are integrated with the riser using a suite of specialty riser joints and components.

The system is based on specialty joints made up and run with the riser. They consist of:

– A crossover joint used to connect the RGH assembly to the rig’s riser at the top and bottom

– A Drill String Isolation Tool (DSIT) to divert flow by hydraulically closing the annulus

– A flow spool to route the diverted flow to the rig or MPD choke manifold

This riser assembly is deployed with integral choke, kill, boost, and hydraulic lines, which makes it immediately available to support drilling operations. A multi-purpose control umbilical that handles both RGH and MPD-RCD applications is available.

RISER GAS MITIGATION

Riser gas typically occurs when gas entrained in the mud system breaks out in the riser. Because it occurs above the control of the subsea BOP, it presents a unique risk to personnel and the rig.

AFGlobal’s RGH system provides a means of safely and effectively handling formation gas by:

– Diverting wellbore flow away from the rig floor

– Can enable a controlled process for removing gas from the riser

– Allowing larger volumes of gas to be handled safely for longer periods of time

– Greatly reducing mud loss

MPD CONVERSION

The unique ability to add MPD capability to the RGH system is possible with a RCD adaptor. The adapter allows a third party RCD to be included in the RGH system, complete with bypass lines. In addition, the RGH umbilical system can be enabled for some RCD operations.

DOWNHOLE ISOLATION

The DSIT riser joint remains in place when an RCD is added to the RGH system. When the RCD bearing/ packer assembly is removed, the DSIT is closed to isolate the wellbore and allow drill pipe to be stripped. Closing the DSIT creates a seal that helps mitigates swabbing and surging effects.

WE ARE FACILITATORS

Our versatile RGH system is the product of expertise developed through close work with operators, contractors, shipbuilders, and service companies.

That comprehensive understanding makes AFGlobal a powerful resource for adapting RGH technology to your rig. Our experts bring exceptional insights and valuable cross discipline skill to every retrofit or newbuild application, so you have the best solution now and in the future.

Installation of an AFGlobal RGH system on your dynamically positioned or moored floating rig provides the next generation of drilling riser technology to keep your drilling operations safe and efficient, and your rig competitive.

RGH SYSTEM: FEATURES AND BENEFITS

The AFGlobal RGH system is comprised of a suite of specialized riser joints and components designed to integrate and complement the riser and rig system.

Its features and benefits include:

– Integral choke, kill, boost, and hydraulic lines that allow deployment with the riser for efficiency and fast availability.

– Deployment through a 60?-in rotary table with 58-in. minimum ID through diverter housing to integrate with riser dimensions for fast, easy running.

– A minimum bore restriction of 19-in. for easy passage of wellbore equipment.

– A proprietary AFGlobal riser flange rated to 3.5M pounds of axial tension with 2,000 psi combined load that allows a smooth transition of stresses when bending movements are encountered.

– 2,000-psi maximum allowable working pressure, which meets or exceeds the needs of most risers on the market today.

– Crossover joints using AFG riser flanges provide easy integration of the RGH system with the rig’s riser below the tension ring and the termination joint.

石油圈

石油圈