The EC Prime? enhanced conductivity fracturing service creates larger, more conductive flowpaths to maximize hydrocarbon recovery from hydraulically stimulated wells. Through a unique combination of fluid dynamics modeling, ultra-lightweight proppant technology, and innovative pumping techniques, each EC Prime service is customized based on your formation’s unique requirements. And, in most instances, enhanced conductivity can be achieved with reduced water and proppant requirements. The benefits: improved short- and long-term production and enhanced fracturing efficiency.

Optimizing the “pillar fracturing” approach

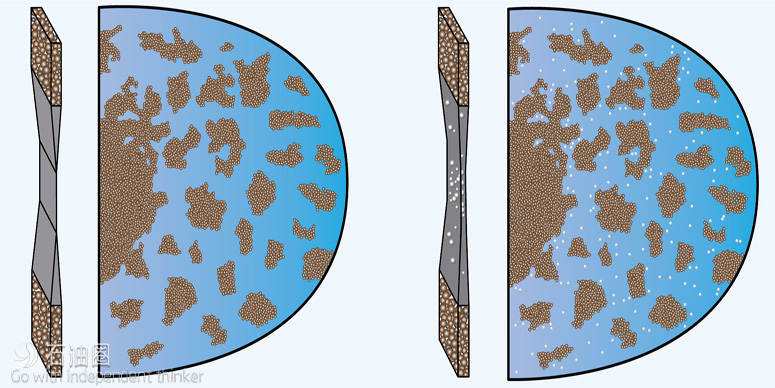

Historically, pillar fracturing techniques use proppant pulsing and hindered settling to create proppant “pillars” capable of holding a fracture open and large flowpaths to permit maximum hydrocarbon flow. However, these conventional pillar fracturing applications often yield inconsistent results. That’s because current industry pillar fracturing solutions aren’t matched to formation properties. Optimizing pillar spacing through design and having a mechanism to hold open pillars under closure stress can be a challenge.

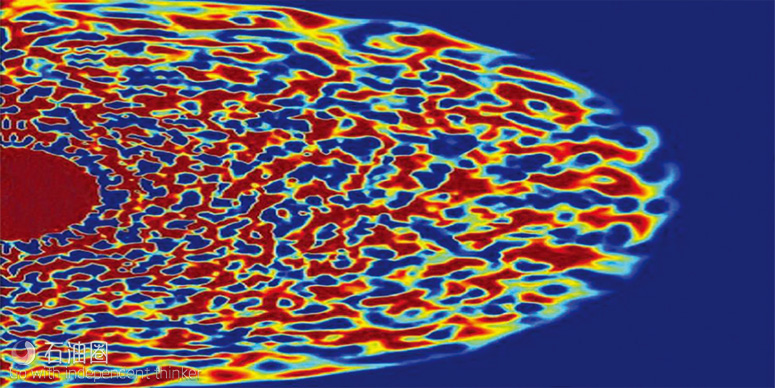

In contrast to traditional pillar fracturing services, the EC Prime service leverages advanced fluid dynamic modeling to match the frac design to the formation’s specific rock properties. As part of each service, experts from Baker Hughes, a GE company (BHGE) determine the optimal treatment parameters (injection rate and pulse time) for a well’s individual fracture geometry (height and width) to create the desired pathways and ensure the necessary proppant support.

Proprietary techniques and proppants

Once an optimal fracture design is completed, the desired distribution of proppant is created by pulsing fluid systems with varying viscosities. The proppant mixture within the fracturing fluid incorporates an engineered distribution of strong, ultra-lightweight proppant. This unique proppant technology possesses a specific gravity close to that of water— allowing it to remain suspended in solution to provide ongoing proppant support even in formations with extended closure times.

This unique blend of technologies ensures that some small, supportive elements remain in place between the proppant “pillars” to eliminate the risk of choke points or closed flowpaths that would trap potential production.

Efficiently improve your recovery

The EC Prime service helps you improve both initial production and ultimate recovery by:

1.Eliminating closure risks between pillars

2.Minimizing the risk of trapped hydrocarbons and/or flow “choke points” within the fracture network

3.Maximizing flow due to optimized pillar-spacing-based, customized formation design

And, because the service delivers proppant reliably throughout the created fracture, and provides additional support in the flow channels between the pillars, this enhanced recovery is typically possible while using less water and proppant than conventional fracturing services. Maximize your stimulation ROI Maximize recovery from your unconventional well effectively and efficiently with an EC Prime service. Contact your BHGE representative today to find out more about how this service can help you maximize returns on your next well.

Maximize your stimulation ROI

Maximize recovery from your unconventional well effectively and efficiently with an EC Prime service. Contact your BHGE representative today to find out more about how this service can help you maximize returns on your next well.

Applications

1.Wells up to 275° F (135°C)

2.Wells with maximum closure stress of 8,000 psi (55 MPa)

Benefits

1.Improved conductivity

– Eliminates closure risks between pillars

– Minimizes risk of trapped hydrocarbons and/or flow “choke points” within the fracture network

2.Enhanced reliable flow channels

– Customized design based on formation properties

– Optimized pillar spacing for maximum flow potential

3.Reduced screenout potential

– Permits lower water and proppant concentrations compared to conventional slickwater treatments

Case Study

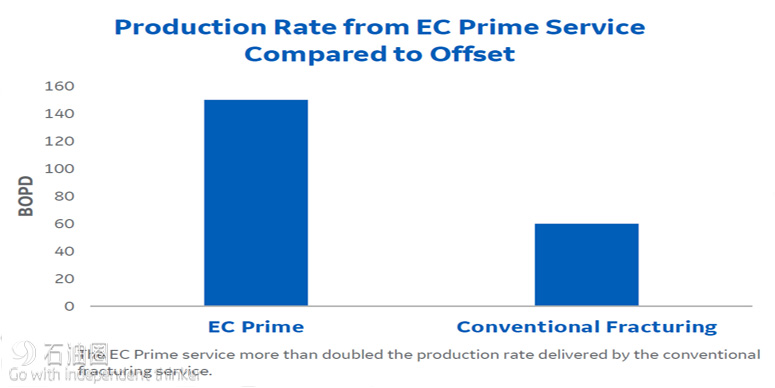

The background

An operator working onshore Indonesia needed a fracturing solution for its new wells. Having used a conventional fracturing approach in the past, the operator had achieved mediocre gains in production, with most wells in the area producing an average of 60 barrels of oil per day (BOPD). Part of the challenge was that the sandstone formation had relatively low permeability of less than 10 mD. The conventional fracturing approaches created limited conductivity within the fracture due to proppant pack damage, which drove down the operator’s production rates.

The proposal

Believing that better conductivity and higher production were possible, the operator asked Baker Hughes, a GE company (BHGE), if the EC Prime? enhanced conductivity fracturing service could be a feasible solution. The EC Prime service is a BHGE pillar fracturing service that creates open, stable hydrocarbon pathways through proprietary pumping techniques that are tailored to the specific formation properties and well conditions where it is applied. Those pathways are also reinforced with ultralightweight

proppant that resists settling and provides extra support for the fracture if it does start to close. BHGE worked with the operator to understand the formation properties and downhole conditions. After that, BHGE personnel implemented an EC Prime service, which involved pumping 70,000 lbs (31,751 kg) of traditional ceramic proppant and 700 lbs (317 kg) of the LiteProp? Prime 108 ultralightweight proppant with the BHGE Spectra Frac? G fracturing fluid.

The results

After BHGE implemented the EC Prime service, the initial production rate from the well was 700 BOPD—much higher than the initial rates from conventional fracturing in offset wells. Two months later, after the initial production rates—which tend to stabilize during the weeks after the job—leveled out, production from the well was still approximately 150 BOPD. The production is still being monitored. During these 2 months, the EC Prime service generated $270,000 USD more revenue for the operator than conventional fracturing in offset wells. The operator was very happy with the results of the EC prime service and has already implemented it in several other wells.

石油圈

石油圈