Best of 2017: Completions And Production Companies, Systems Garnering Attention

(1)CalVisc

Calfrac was awarded in excellence in well completions for its CalVisc system. According to the company, CalVisc was developed as an alternative to traditional crosslinked fluid systems and offers proppant placement technology equivalent to crosslinked fluid systems. The CalVisc system increases proppant pack conductivity compared to guar-based fluid systems while generating significant viscosity at low shear rates. Calfrac reported that the CalVisc system requires fewer chemicals, improving an operation’s economics and reducing operational and HSE complexity with fewer trucks on location and less use of chemicals. A CalVisc customer reported that using the system simplified the execution of its company’s fracturing job and allowed it to increase pump rates with minimal impact on pumping pressures. The customer also said the system helped reduce heating demands, which led to overall cost reductions.

(2)Comtech Industries

Comtech Industries was awarded for its achievements in environmental stewardship. The company was recognized for its overall safety and operational performance, its efforts to reduce land disturbances with its DYNA tanks and the nearly 7 million pounds of waste the company has prevented from going into landfills. Comtech Industries offers water treatment systems and drilling service programs designed to make natural gas exploration more efficient, effective and environmentally friendly. The company provides water treatment and drilling programs, including implementation of its “Wellpad of the Future” in the Marcellus and Utica basins. Results of the company’s efforts in the northeast have included reduced offsite truck hauling, the elimination of impoundment pits and reductions of waste solids. These efforts have resulted in a reduced environmental footprint in the region, according to the company.

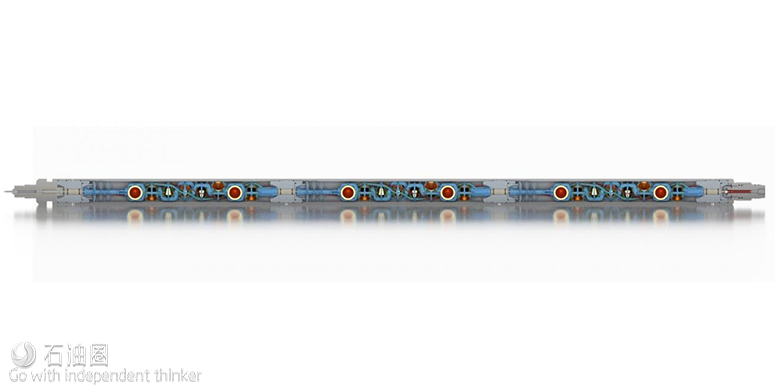

(3)DynaStage

DynaEnergetics was recognized as one of the top manufacturers of the year for its achievements with its DynaStage selective perforating system. According to DynaEnergetics, the DynaStage system enables operators to transition away from traditional field wiring and assembly of perforating guns. In one case in the Denver-Julesburg Basin an operator deployed more than 7,000 consecutive DynaStage units without a misfire or a failure. DynaStage is a fully disposable, maintenance-free system that utilizes TopFire surface connection technology in place of detonator connection wires. The tool can be used for natural completions or horizontal shale gas fracture stimulation. DynaEnergetics offers solutions for perforating and well completion systems worldwide for both conventional and unconventional operations as well as pipe recovery and well abandonment.

(4)PX Pressure Exchanger

Recognized as one of the notable new technologies of the year is Energy Recovery’s PX Pressure Exchanger, a system that helps desalination plants run more efficiently and profitably. The PX Pressure Exchanger recycles energy that would otherwise be lost in the desalination process. The system captures hydraulic energy from the high-pressure reject stream of seawater and transfers this energy to low-pressure feed water with up to 98% efficiency without the need for electrical power. The result is a significant reduction in energy consumption over previous methods, according to Energy Recovery. The system features only one moving part, created out of a corrosion-proof ceramic that the company states is three times more abrasion-resistant than steel. Energy Recovery’s PX Pressure Exchanger works for both high-pressure seawater and low-pressure brackish reverse-osmosis systems.

(5)Eureka Resources

Eureka Resources was recognized as a leading company in water management in the Marcellus and Utica basins. The company provides oil and gas E&P companies with a variety of water management and treatment services, including waste/wastewater transportation services, treatment of wastewater at advanced centralized wastewater treatment facilities, storage of raw and treated wastewater and production of usable byproducts. Its water treatment system involved the use of mechanical systems to minimize wastewater volumes and generate freshwater effluent and reusable byproducts, including high-purity sodium chloride and calcium chloride salts. The company operates three wastewater treatment facilities in the northeast to service companies working in the Marcellus and Utica basins. Those facilities enable oil and gas producers to reduce transportation and production costs as well as the amount of freshwater needed for drilling and production operations, the company stated.

(6)FortisTRAC

Fortis Energy Services’ FortisTRAC system was recognized as one of the industry’s best new technologies of the year. The workover rig technology delivers real-time data to operators along with the ability to add customizable functionality and key performance indicators. According to the company, the FortisTRAC system includes a mobile command center onsite with fully functioning satellite internet services. The system allows customers to view what is happening live on location and downhole from their offi ce or via a mobile device. The system also compiles and archives the tracked data onsite to create a history to aid in future continuous improvement. Additionally, the FortisTRAC assists in post-accident investigation to see data output from each piece of equipment to ensure operators followed proper operating procedures when an incident occurs.

(7)Hydralift rod lifting device

Hydralift RMOW was awarded for its hydraulic rod lifting device. According to Hydralift, the tool is used to replace conventional rod lifting methods. The device allows a single operator to adjust pump spacing on a rod pump well safely, easily and more efficiently. It can be used to remove or induce a tag on a rod-pumped well by synchronized hydraulic pistons, which transfer the weight of the rod off of the pumping unit’s carrier bar and onto the wellhead. A spacer is then introduced in the length necessary for the application, and pistons transfer the weight of the rodstring back onto the carrier bar. The Hydralift system has been rated to safely lift 40,000 lb. Its hoses, fittings, cylinders and pump are rated to a safe working load of 10,000 psi.

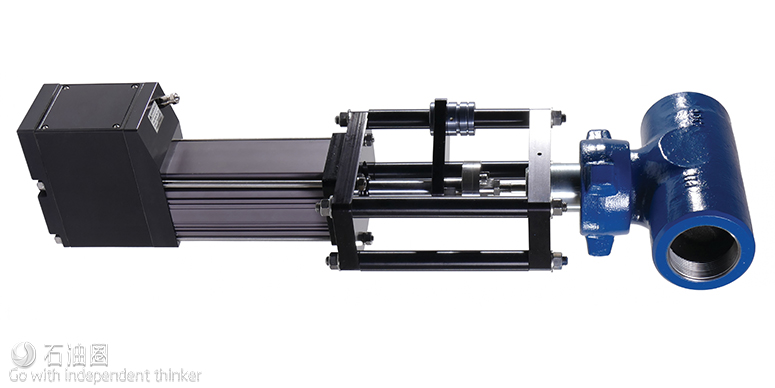

(8)Tritex II

Norriseal WellMark was recognized for its Tritex II electric actuator. The Tritex II was deployed in the Denver- Julesburg Basin for a Denver-based E&P company that was looking to enhance its environmental stewardship and resolve the economic impact of fugitive emissions. Beginning in 2014 the company began replacing 150 pneumatically controlled valves in its gas-lift injection application with Norriseal Series 2200 control valves and CBV 2500 control ball valves, both fitted with Tritex II electric actuators. The Tritex II actuators require less power and operate via solar power systems. The applications of the actuators resulted in the elimination of about 56.6 Mcm/year (2 MMcf/year) in fugitive emissions by the E&P company. By eliminating emissions from the valves, the company is recovering an estimated $2 million per year in marketable natural gas, according to Norriseal WellMark.

(9)Miraah project

Petroleum Development Oman (PDO) and GlassPoint Solar were honored for combined efforts on the Miraah solar energy project operating in Oman. Miraah harnesses the sun’s energy to produce steam that is subsequently used in thermal EOR to recover Oman’s heavy oil. According to GlassPoint Solar, the project replaces natural gas usually burned to produce steam, saving more than 300,000 tonnes of carbon emissions annually. To maintain continuous steam injection, solar steam is injected during the day, and steam produced by burning natural gas is injected at night. Studies from PDO and Stanford University found that solar could provide up to 80% of a field’s annual steam requirements, significantly reducing the amount of gas consumed for thermal EOR. The project broke ground in 2015 and produces more than 1 GW of thermal energy.

(10)Clean Fleet

U.S. Well Services (USWS) was awarded for its Clean Fleet well completion technology. USWS’ Clean Feet is a fully electric fully mobile well stimulation system powered by natural gas. According to USWS, Clean Fleet helps reduce emissions by 99% and decreases sound pollution while generating operational cost savings by up to $40,000/day. Clean Fleet’s pump truck features independent 1,750-hp engines that run on electric power generated by 5.7 MWe (megawatt electrical) natural gas-fueled turbine generators. According to USWS, the system results in hydraulic fracturing operations that run cleaner, quieter and safer and are less disruptive to neighboring communities. USWS stated that by utilizing natural gas, the Clean Fleet system helps eliminate about 25 diesel truck deliveries to the well site that are typically required for horizontal fracturing completions.

石油圈

石油圈