ROMAX™ Water Clarifiers

Dow’s ROMAX series of water clarifiers are designed to separate oil from produced water and reverse emulsions. They help ensure that oil levels are low enough such that the water can be reused and integrated into a system, reducing residual oil-in-water from more than 1,000 ppm to below 20 ppm. The clarifiers do not require the inversion that conventional products often require to remove the water clarifier from the hydrocarbon prior to dosing.

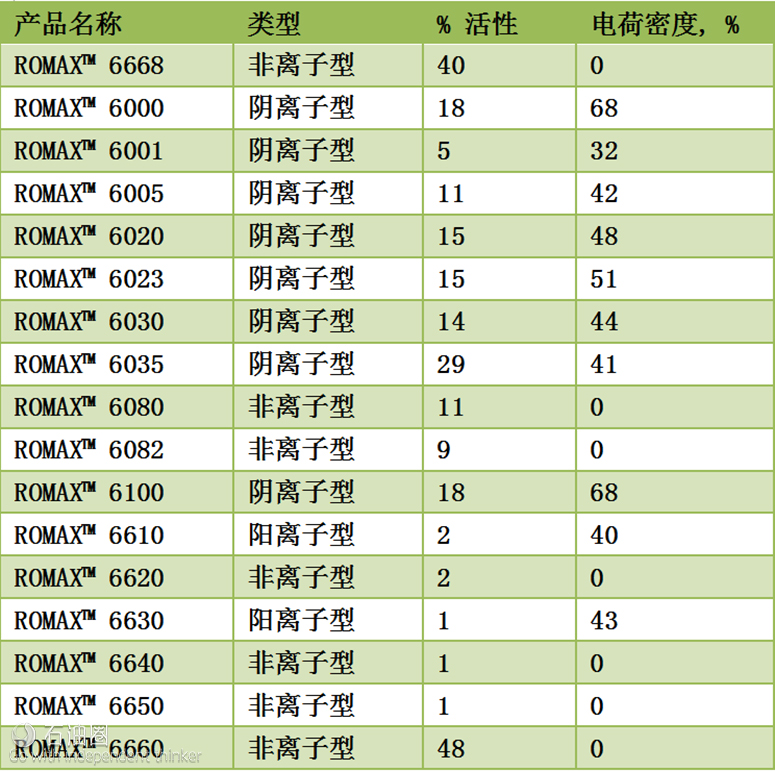

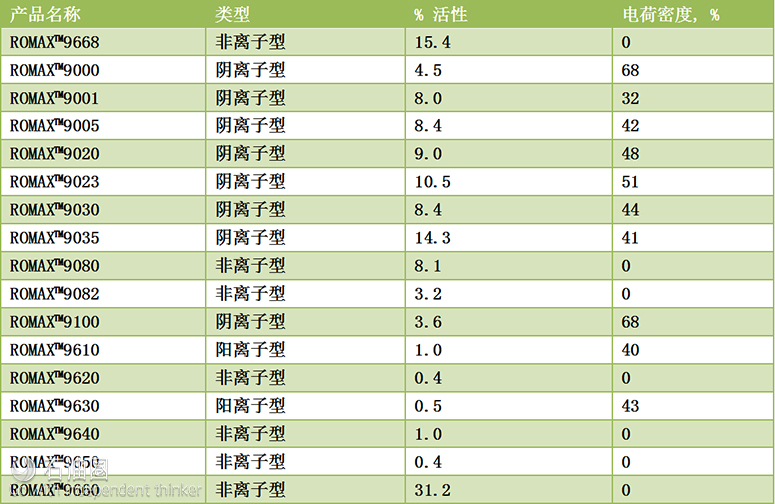

Dow provides two series of Water Clarifiers, The ROMAX 6000 Series; fully formulated anionic, cationic and nonionic water clarifiers that are ready to use as soon as they arrive at the field and the ROMAX 9000 Series; freeze-stabilized formulations for use at temperatures as low as -40 ºF (-40 ºC).

Uses:

Oilfield Production Phase Separation

Advantages:

Excellent oilfield water clarifier

Ready to dose

Low-viscosity material

Excellent temperature stability

Available as freeze protected formulation to -40°C

Raising the Bar in Oil/Water Separation

Tightening environmental regulations and the limited supply of fresh water are driving the oil and gas industry to seek new solutions for reducing oil in water prior to discharge and to employ reuse schemes in water-intensive activities such as boilers and direct injection for enhanced oil recovery processes. ROMAX™ Water Clarifiers from Dow provide a valuable solution for separating oil from produced water and reverse (oil-in-water) emulsions, helping to protect both the environment and production equipment.

Building on the Basics

Dow offers water clarifier solutions to meet a wide variety of final formulation needs. To custom-design your own clarifier formulation, we offer the ROMAX™ 7000 series of bases. We also offer fully formulated products based on these well-established anionic bases. The ROMAX 6000 series of anionic, cationic and nonionic water clarifiers are fully formulated and ready to use as soon as they arrive at the field. And for colder climates, our ROMAX 9000 serie of water clarifiers are freeze-stabilized formulations for use at temperatures as low as -40 ºF (-40 ºC).

Ensure Compliance, Save Money

Re-injecting even small quantities of oil back into the environment through produced water can quickly add up, negatively impacting your bottom line and raising a red flag to environmental regulators. Globally, oil and grease specs on discharged water have been established to ensure the amount of oil in water is at a safe level for disposal or reuse. Specifications vary from country to country in a range of more than 15-50 ppm.

When the goal is reuse rather than discharge, ROMAX™ products help ensure that oil levels are low enough such that the water can be confidently reused and integrated back into the system. With dosage rates of 1-20 ppm of ROMAX products, it is possible to reduce residual oil-in-water from more than 1,000 ppm to below 20 ppm.

Aqueous-Based Chemistry Enables Field-Ready Formulations

Dow’s application expertise has allowed us to develop fully formulated ROMAX™ Water Clarifiers. Conventional products use a hydrocarbon-based solvent that requires a laborious inversion process to remove the water clarifier from the hydrocarbon prior to dosing. But our aqueous-based products require no such inversion, meaning that they are ready to use upon arrival and can be dosed immediately.

石油圈

石油圈