The TenarisHydril Wedge XP connection provides the exceptional over-torque performance needed in many production strings typically used in horizontal wells for shale applications. The connection’s torque capacity is achieved thanks to the renowned robustness of the Wedge thread design combined with a pin-to-pin backup mechanism. Maximizing the value for oil and gas operators, the TenarisHydril Wedge XP connection reduces running times due to lower threads per inch of the profile and a rugged thread design that significantly decreases rejects and re-makeups. Connection make-up is easy enough to avoid the need for a torque-turn chart.

FEATURES

• Available in sizes 4 1/2″ to 5 1/2″.

• TenarisHydril Wedge thread design provides maximum over torque capacity to manage longer laterals.

• Pin-to-Pin back up mechanism granting additional torque capability to handle rotation.

• Robustness of Wedge profile reduces number of rejects / re-make-ups.

• 100% tension

• 100% compression

• Lower threads per inch profile (3.4 vs. 5 TPI of a typical BTC modified), rugged coarse thread design and deep stabbing allow for speed of installation, enhancing the performance of an industrial drilling approach.

• Easy Make-up: No need of Torque-turn chart. Standard field equipment fully sufficient for regular make up.

• Reduced hoop stresses on coupling compared to BTC profile connections. ..Standard Bevel of 20°

• Make up indicator in pin with 20″x1″ white locator stripe.

APPLICATIONS

• Shales

• Casing while drilling

• Rotating while cementing

• Production casing and liners

Case study1

YPF, the National Argentine oil and gas company, wanted to promote reliability and reduce risks in two drilling with casing operations in mature fields in the Argentine provinces of Santa Cruz and Mendoza.

YPF needed to reduce operational times in two wells where they were using the drilling with casing technology. One of the wells had a total depth of 2,153 meters and was located in the San Jorge Basin in Santa Cruz, while the other one had a total depth of 662 meters and was located in the Neuquén Basin in Mendoza. A connection with extra torque resistance that could ensure a high margin of safety was required to withstand the drilling conditions and reduce the risk of having to pull out the string during the operation. The chosen connection had to be robust and present good runnability in order to materialize the operational advantages that drilling with casing brings. YPF was also looking for a cost-efficient solution for its operations in mature fields.

Solution

Exceptional torque resistance

The company decided to run a production casing string with 5 ?” 17# K55 TenarisHydril Wedge XP connections, the latest incorporation of the Wedge Series. With an operative torque of 17,685 ft-lb, the Wedge XP offers exceptional over-torque performance, achieved thanks to the remarkable robustness of the Wedge thread design combined with a pin-to-pin backup mechanism.

As with other TenarisHydril Wedge connections, its lower threads per inch profile (3.4 vs. 5 TPI of the BTC-modified connections), rugged coarse thread design and deep stabbing allow for speed of installation.

The robustness of the TenarisHydril Wedge profile also reduces the number of rejects and re-make-ups, while the connection makeup is simple enough to avoid the need for a torque-turn chart. This enhanced runnability offered by the Wedge XP connection significantly improves installation times.

Integral solutions for the oil and gas industry

For the first runnings, Tenaris’s field service and technical sales specialists worked onsite with YPF to ensure that the correct practices were followed and the products were properly installed and used.

Tenaris also offered YPF its make-up quill service, an accessory specifically designed by Tenaris. This cost-efficient solution allows for the transmission of torque from a top drive to the casing through a simple and reliable mechanism.

Results

Improved reliability

Through the use of the TenarisHydril Wedge XP connection, YPF achieved smooth operations in both Mendoza and Santa Cruz. This solution was not only cost efficient, but it also allowed the operator to make the most of the drilling with casing technique.

In the San Jorge basin, YPF drilled 1,703 meters with a running performance of 3/4 mins for the complete joint make-up, conducting the operation with zero re-makeups and rejects. During the operation, the weight on bit (WOB) reached up to 14 tons with a torque at surface that increased up to 14,500 ft-lb and was successfully withstood by the Wedge XP. YPF acknowledged that the Wedge XP is the only connection that can handle this torque level in such a K55 pipe with a slim wall.

In the Neuquén basin, the operator drilled 360 meters (302 to 662 m). The WOB reached up to 6 tons and the Wedge XP connection easily withstood a torque of 7,500 ft-lb.

In both experiences, and confirming the robustness of the connection, members of the drilling teams underlined that this product seemed to perform as robust as a drill pipe.

YPF highlighted that it achieved a record depth for its drilling with casing operations in the San Jorge basin, one of its most important areas for this type of drilling technique. A survey conducted by YPF to evaluate the results of the operation had a maximum score of 95/100 for the Wedge XP connection, which was approved by YPF for use in deep drilling with casing operations.

Case study2

Noble utilizes pad drilling, which often include long laterals and severe doglegs to satisfy spacing requirements and anti-collision issues. These expected challenges require the use of a connection with exceptional torque capability should the need arise to ream the casing to target depth.

In addition, Noble’s standard operating procedure includes rotating while cementing. This is a Halliburton best practice and API Standard 65-2 recommendation that helps to maximize the displacement efficiency of the drilling fluid aiding in cement placement. The ability to rotate casing throughout the cement job enhances the cementing hydraulic seal and helps to maximize wellbore integrity, which increases the economic life of the asset. This operation necessitates a high torque connection to prevent the casing string from stalling out during the cementing process.

Solutions

A robust and reliable connection

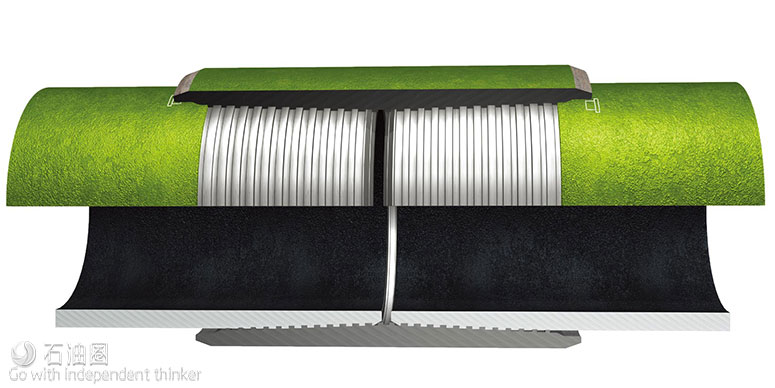

TenarisHydril Wedge XP is a newly developed threaded and coupled connection, offering exceptional torque capacity and compression efficiency through the simultaneous engagement of opposing flanks generated by the dovetail thread. A pin-to-pin back up mechanism provides additional torque capability for rotation.

As with other TenarisHydril Wedge connections, Wedge XP reduces running time due to lower threads per inch of the profile and a rugged thread design promoting runnability. The make-up indicator allows for visual confirmation of acceptable make-up position, providing potential cost savings by eliminating the need for a torque-turn chart.

Results

High Torque, High Speed

A total of 388 joints of 5 ” 20# P110-IC TenarisHydril Wedge XP were run in hole as production casing, reaching a total depth of 16,566’ MD / 6,010’ TVD. Throughout the run, an average make-up speed of 15 seconds per connection was recorded.

Wedge XP demonstrated its torque capability as it withstood a maximum torque of 28,500 ft-lbs generated during rotating while cementing under a dogleg severity of 11°/100’ @ 6,333’ MD.

石油圈

石油圈