MEASURE, MONITOR, CONTROL

Current technologies used to detect and enumerate bacteria type and population are limited in terms of accuracy, potential for contamination, and response time.

Microbial InstaCheck* real-time bacteria measurement, monitoring, and control service is a rapid, cost-effective, easy-to-use, portable onsite service that affords full evaluation of field microbial control strategy.

The service uses both new and established bacteria enumeration techniques, coupled with our proprietary ChemWatcher* integrated chemical management software. It is powered by the Avocet* production operations software platform to deliver informed, real-time decisions regarding microbiological control strategies to drive operational efficiency, safety, and performance.

Combined with tailored chemical treatments, the service enables operators to measure, monitor, and control bacteria problems like never before. The service identifies the location of bacteria populations, evaluates the effectiveness of current biocide applications, and confirms the future bacteria control strategy.

Using the Microbial InstaCheck service for bacteria mapping decreases the timeframe allocated for microbiology surveys and reduces cost while providing high-quality data, enhancing bacteria management; operators can conduct, analyze, evaluate, and report a full-field bacteria survey in a matter of hours.

ANALYSIS TECHNIQUES

Microbial InstaCheck service enables direct comparison, analysis, and interrogation of data sourced from the following techniques to deliver an accurate field bacteriological map.

Serial dilution method

With a significant body of historical analysis data derived from this technique typically available per asset, serial dilution is perhaps the most widely used analysis technique for bacteria analysis in the oil field. Though portable and relatively easy to use in the field by trained personnel, limitations of this technique are well known:

1.NACE standard procedures (TM0194-2014 and TM0212-2012) are rarely followed.

2.Water salinity matching for bottle media is infrequent and difficult to manage effectively.

3.It is challenging to deliver bacteria testing and monitoring conditions in serial dilution bottles that are fully representative of live systems and processes.

4.Serial dilution takes up to 28 days to return results, at which point infield bacteria populations can be significantly different, leading to treatment programs being reactive rather than proactive.

Thus, it is desirable to augment serial dilution results with rapid field analysis methods, provided results may be accurately compared.

ATP method

Adenosine triphosphate (ATP) is an enzyme used by living cells to yield chemical energy in support of cell activity. As a result, ATP may be used as an indicator (measure) of biological concentration. In oilfield systems, this technique may therefore be used to evaluate bacteria concentration.

Though ATP analysis is ideal for bacteria analysis in food and medical applications, attainment of reproducible results in oil and gas applications can present a challenge because of hydrocarbon contamination potential. Though latest-generation ATP methods are designed for increased robustness in industrial applications, oil and gas samples, which routinely contain a variety of components, present high potential for test interference.

The ability to undertake accurate historical and current field data trend analysis and evaluation is critical to the effective application of this technique.

MICROBIAL INSTACHECK SERVICE

Rapid field survey and treatment strategy

The Microbial InstaCheck service enables rapid bacteria survey on an entire field or production equipment sequence at multiple points to determine bacteria content, location, and magnitude of any bacteria problem—all within the same day.

Analysis of collated field data confirms bacteria population size and location, enabling the development of an effective, targeted treatment to clean the equipment, remove the bacteria, and implement future, measurable control treatments to prevent reoccurrence.

The Microbial InstaCheck service can provide accurate bacteria enumeration within minutes. As a result it is now possible to screen bacteria control measures onsite, in real time, to confirm the effectiveness of a bacteriological treatment (microbiocide) strategy throughout the treated production system.

Benefits

1.Accurate, precise bacteria enumeration via the living bacteria viability enumeration test technique

2.Ability to differentiate aerobic and anaerobic bacteria using Schlumberger protocols

3.Determination of bacteria in a wide range of sample matrices

4.Proven reliability track record (more than 15,000 tests in 200 different produced water sources)

5.Application over a wide range of water chemistry and biological conditions, including production, drilling, and fracturing treatments

The result is reported as a dye concentration, which is directly translated to familiar terms such as colony-forming units or serial dilution bottle turns.

CHEMWATCHER SOFTWARE

Real-time decisions to drive performance

ChemWatcher integrated chemical management software, powered by the Avocet production operations software platform, enables informed, real-time decisions to improve system performance.

Global expertise

The system leverages Schlumberger global specialist knowledge and technical expertise, continually adding value throughout each stage of production.

Software integration

This software solution integrates with market-proven tools, including PIPESIM* steady-state multiphase flow simulator, OLGA* dynamic multiphase flow simulator, and dbrHydrate* fluid analysis software to manage the workflow related to chemical applications, injections, and production processes.

Complete chemical management

ChemWatcher software enables visualizations of asset status and trends from simple traffic lights to detailed interactive reports, facilitating real-time decisions regarding production chemical applications to drive operational efficiency and safety.

In addition to real-time production performance monitoring and analysis, ChemWatcher software is enabled for SCADA and telemetry and works as a central repository hub, providing information exchange and analytics for all data relating to:

1.flow assurance and integrity management

2.production and product performance

3.inventory management and commercial performance

4.laboratory data and trend analysis.

Full integration of the Microbial InstaCheck service within ChemWatcher software offers real-time field bacteria count and KPI dashboards, microbiocide dosage regimen control, historical data comparison, and direct interrogation and analysis of bacteria results by our in-house microbiologists to ensure implementation of efficient bacteria control measures.

PREVENT MICROBIOCIDES INHIBIT HARMFUL BACTERIAL ACTIVITY

Solutions

Our microbiocides are proven to control a broad spectrum of anaerobic and aerobic bacteria, particularly sulfate-reducing bacteria for water injection and produced-water systems. These products work both through direct microbiological activity and by modifying the environment to prevent bacteriological activity.

Product selection

Inorganic microbiocides are cost-effective disinfectants used in all types of industrial systems, and organic microbiocides are a less corrosive option that can be used as the sole treatment or together with inorganic alternatives.

Application monitoring

All our microbiocide product applications may be supported in situ by monitoring programs. This includes the installation of devices such as sidestream equipment to develop sessile biofilm colonies on retrievable studs and real-time system mapping and monitoring through the Microbial InstaCheck service.

When selecting suitable chemistries for maximum performance, several factors must be assessed:

1.mammalian and marine toxicity

2.ease of handling

3.solubility in oil and water

4.compatibility with materials of construction and other process additives

5.ability and requirement to penetrate biofilms and or solid deposits within the system

6.cost efficiency.

Case Study

BACTERIA MITIGATION WITH MICROBIAL INSTACHECK SERVICE

CHALLENGE

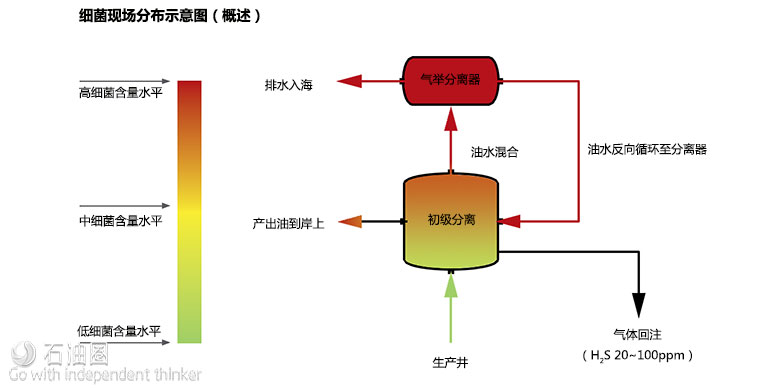

An international operator needed to conduct complete offshore bacteria field mapping of 36 production platforms with the aim of identifying and implementing an enhanced bacteria management program.

SOLUTION

Schlumberger field personnel conducted rapid infield analysis of all 36 platforms over a 10-d period using the bacteria metabolism test water bacteria enumeration technique. Interpretation and evaluation of data was conducted infield with the Microbial InstaCheck service to deliver an overview of field bacteria location and concentration.

Typically, on each platform, sample collection and processing took approximately 2 hours. The team issued interim bacteria field map reports to each platform on the same day.

The majority of producing wells displayed bacteria concentration of <103 colonies/mL. However, high levels of system bacteria were measured after treatment in the primary separators, immediately prior to and within the air lift separator units.

Produced water entering these units had bacteria levels of 105 colonies/mL, with water leaving these units highly contaminated at 108 colonies/mL.

Bacteria-laden oil skims from the air lift separator units were being recycled back to the primary separators resulting in infection of these locations as well as the oil to shore export line.

RESULTS

Analysis concluded that the source (and incubator) of system bacteria was the air lift separator units.

Schlumberger recommended isolation and treatment of each bacteria infected area (air lift separator units, separator, and the oil-to-shore line) with EPT-3144 cleaning and pickling chemical followed by regular, location-tailored biocide treatment with broad-spectrum-biocide MB?5028 to return the system to optimal operating conditions.

Schlumberger production technology specialists deliver targeted, integrated strategies that help to decisively remediate production issues such as deposit formation and naturally occurring gases, enabling customers to safely restore and improve flow performance and revenue while avoiding costly repairs and shutdowns.

Firmly established at the forefront of technology, Schlumberger has a full service offering that integrates pioneering chemical and process solutions, equipment, and software with unrivaled technical expertise.

Working with the world’s largest oilfield services provider, customers benefit from a truly unique combination of outstanding technological capabilities and improve their understanding of how to successfully address production challenges in an increasingly competitive marketplace.

The team’s global footprint and extensive suite of technologies helps customers to reliably and efficiently maximize production—regardless of system complexities or geography.

石油圈

石油圈