JetPulse™ High-Speed Telemetry Service

THE RIGHT DATA AT THE RIGHT TIME TO MAKE THE RIGHT DECISIONS

Today’s challenging drilling environments such as deepwater or mature fields have significantly increased the need for real-time data to ensure accurate well placement and maximize drilling performance and efficiency. This increased need places higher demands on telemetry systems to transmit larger data sets and higher-resolution images without sacrificing accuracy or negatively affecting rate of penetration (ROP). The JetPulse™ high-speed telemetry service meets these higher demands for data by providing consistent and configurable high-speed transmission of real-time drilling dynamics and formation evaluation measurements, enabling quicker decision making for accurate well placement, improved well control, and increased drilling efficiency. With more and faster data transmitted by the JetPulse service, you can reduce the flat time on the drilling curve while enhancing reservoir understanding to accurately place the wellbore for maximum reservoir contact.

The JetPulse service uses a mud-pulse telemetry system to send data to the surface by using pressure pulses in the drilling fluid. At surface, the pressure pulses measured by multiple pressure transducers are combined for maximum detection efficiency. The JetPulse service can transmit up to 18 bps of physical data, and, with the JetPack 3D™ data management service, the JetPulse service is able to deliver transmission rates of over 140 bps through compression. In addition, the JetPack 3D service allows you to configure which data you need most at the current location on the well plan. In collaboration with our customers, we can utilize the combination of the JetPulse and JetPack 3D services to provide consistent and configurable high-speed, real-time data that enable you to make timely decisions and maximize asset value.

FEATURES

(1)Encoding method delivers high and consistent data rates across a wide range of depths

(2)Configurable data delivery enables you to have the Right Data at the Right Time to make the Right Decisions

(3)Industry-leading lost circulation material (LCM) tolerance of any high-speed mud-pulse telemetry system

BENEFITS

(1)Drill to Produce

Place wells accurately with fast, high-quality geosteering images and measurements to maximize reservoir contact

(2)Enhance Reservoir Understanding

Receive more information faster about your reservoir rock and fluid properties in real time to make optimal decisions on geosteering or where to take other logging-while-drilling (LWD) measurements, such as formation pressure and fluid sampling with the GeoTap® and GeoTap IDS sensors

(3)Reduce Well Time

Maximize drilling efficiency and ROP with timely drilling dynamics data

Minimize drilling risks with real-time information of wellbore stability and pressure management

Case Study

JETPULSE™ HIGH-DATA-RATE TELEMETRY ENABLES OPERATOR TO ANTICIPATE AND REACT TO POTENTIAL PROBLEMS BEFORE SIGNIFICANT NPT CAN OCCUR

CHALLENGE

Obtain frequent updates of real-time PWD data, formation evaluation data, and rotary steerable data, which conventional telemetry could not provide

SOLUTION

To provide the necessary data, the JetPulse™ high-data-rate telemetry system with compression transmits data up to four times faster than conventional telemetry

RESULTS

(1)Achieved fastest mud pulse telemetry rates for this operator in this country

(2)Made completion decisions based on real-time data

(3)Provided recorded data results in real time

(4)JetPack 3D™ downhole data management platform offered eight customizable data packet options for optimum results in different drilling scenarios

The fields in the Caspian waters of Azerbaijan are one of the most difficult places to drill. Wells in this field have borehole stability issues, moderate formation pressure, and a high overbalance in the production zone. To drill wells successfully in such a challenging environment, quick decisions must be made in order to adjust drilling parameters such as bit rotation speed and equivalent mud weight (EMW). Making quick decisions requires receiving quick data updates – and a large amount of data. JetPulse™ high-data-rate (HDR) telemetry met the urgent need for pressure-while-drilling (PWD) real-time data updates for the drilling team, without losing data density for formation evaluation data to assist the geologists with their lithology analysis.

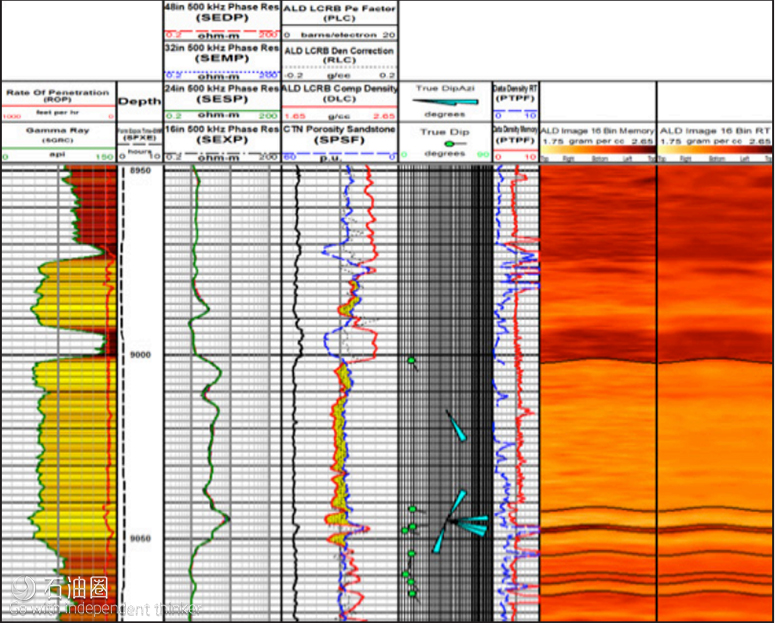

Sperry Drilling controlled borehole stability issues on this well by using a low-energy drilling technique (spinning the drill bit less than 140 rpm) and carefully monitoring the well for excessive vibration. For early detection of borehole instability, HDR images with the best possible resolution were needed. JetPulse telemetry provided very-high-frequency updates and a

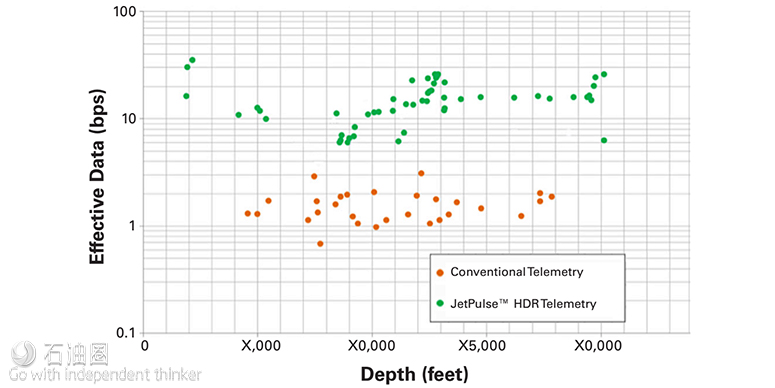

high-resolution log for geologists, along with recorded data quality at real-time transmission speed. In a challenging environment, JetPulse telemetry offered a custom solution, providing telemetry data rates that were up to four times faster than conventional telemetry.

High inclination and borehole instability were key challenges for this well. To get to target depth in this formation, the drilling team had to drill at a 70-degree inclination through unstable shale zones above the targeted reservoir oil section. While drilling through each layer of shale, it was critically important for the drilling team to have the necessary data in order to make adjustments to the drilling parameters and EMW, and to also ensure that the low-energy drilling application was maintained while the wellbore passed through the unstable shale zones. Successful drilling in such a challenging circumstance requires intensive monitoring and frequent adjustments. If the mud weight is too light, high-pressure water may flow out of the wellbore. Yet, if the mud weight is too heavy, undesired fractures in the formation can occur, and thus frequent pressure data updates are essential. This intensive level of monitoring requires a tremendous amount of data to be transmitted in a very short amount of time.

In a challenging environment where the operator had to deal with borehole stability issues, moderate formation pressure, and a need to maintain an overbalance in the same wellbore, JetPulse telemetry delivered positive results. With this system, the data density needed by the drilling team and geologists was received in seconds instead of minutes, enabling the team to base its decisions on real-time data. When minutes make the difference, JetPulse telemetry delivers up to 6,000 pulses per hour, while conventional telemetry can only deliver up to 1,500 pulses per hour.

The operator needed the JetPulse HDR telemetry to provide high 16-bit resolution PWD measurements, formation evaluation data, and rotary steerable data, which the JetPulse telemetry system could deliver when slower conventional compression data telemetry could not meet this requirement.

The JetPulse HDR telemetry offers a way to compress wellbore data in order to increase data density. Sperry Drilling offers both compressed and non-compressed data format options to optimize both data density and the speed of data updates. In addition to JetPulse HDR telemetry, the flexibility offered by the JetPack 3D™ downhole data management platform gave field personnel the freedom to choose a customized set of up to eight data packet options, rather than the two data packet options available with a conventional telemetry system. This increased flexibility permitted the Sperry Drilling team to create a specific selection of data focused on PWD data, thus generating faster and more frequent PWD updates and achieving PWD in the non-compressed format at a remarkable 5-second update rate.

The JetPulse telemetry service delivered the fastest mud pulse telemetry rates recorded to date

for this operator in this country, empowering the operator to make timely decisions for overcoming difficulties and to drill the well successfully and efficiently. JetPulse telemetry delivered the necessary quality and frequency of the PWD data, rotary steerable data, and formation evaluation data at a consistent and effective data rate across all depths. Using JetPulse HDR telemetry, the operator was able to carefully monitor any changes in parameters that might cause a potential problem and to react quickly to the dynamic drilling environment before significant nonproductive time (NPT) was incurred. The operator reached the production zone within budget and without any NPT due to borehole instability. With this success, the operator now plans to apply the JetPulse HDR telemetry service in conjunction with the JetPack 3D platform, with its customizable data transmission, in another nearby gas production field to address the specific challenges of each well.

石油圈

石油圈