Recently, exploration and development of shale plays in Argentina, such as the Vaca Muerta, have begun. To achieve commercial production, this type of reservoir must be stimulated by hydraulic fracturing using large volumes of water.This paper discusses aspects of water logistics necessary during the well-completion phase, fracture-treatment designs applied in Vaca Muerta, and laboratory studies performed on flowback and produced water to help evaluate the potential

for water reuse.

Introduction

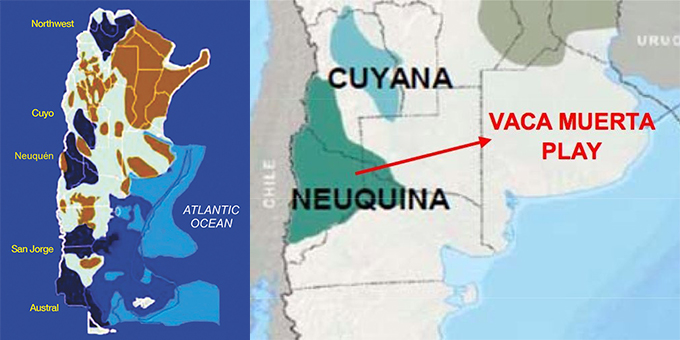

Well stimulation using hydraulic fracturing has been used widely for producing oil and gas reservoirs in Argentina since the 1960s. This stimulation technique has been applied in the five hydrocarbon producing basins shown in Fig. 1, as well as in a variety of formations and types of reservoirs, such as conventional, tight, and, more recently, shale. The majority of shale exploration and development has been in the Vaca Muerta formation, but work has also been assessed in other formations, such as Los Molles, Cacheuta, D-129, and Agrio. Experience gained related to water management in these shale plays during the completion of more than 40 wells (more than 200 hydraulic fractures) by different operators is presented in the paper. Furthermore, laboratory studies were conducted on treated and untreated flowback water, and assessment of its use as fracturing-fluid water is presented.

Water Sources and Stimulation

Given the economic potential of the Vaca Muerta play, the focus lies on this reservoir. The primary sources of water in the Neuquén basin used to develop these hydrocarbon resources are rivers (Neuquén, Limay, and Colorado), lakes, reservoirs (Cerro Colorado and Pellegrini), or groundwater sources, such as wells with low salinity. These types of wells for water supply need a permit from the regulatory authority, and produced water is not suitable for human consumption orfarming.

Types of Systems. The following systems used fresh water and contained chemical additives to perform various functions:

SW—Contained a friction reducer and friction-reducer breaker

LG—Contained a gelling agent, buffer, and breaker

XL—Consisted of a buffer, gelling agent, crosslinker, and breaker

Additionally, each of the fluid systems also typically contained a biocide, clay inhibitors, and surfactant additives.

Types of Treatment. The most common hydraulic-fracturing treatments performed in different plays in Argentina were hybrid fracturing designs. The greatest volumes of water by stage correspond to reservoirs of gas and wet gas in hybrid treatment designs for both SW/LG (Los Molles) and SW/LG/XL (VacaMuerta).

A statistical analysis regarding the type of hydraulic fracture in Vaca Muerta was performed for six fields, A, B, C, D, E, and F. Thirteen wells and more than 65 hydraulic fractures were analyzed. In general, average water volume per stage varied according to the fluid reservoir; for oil wells, the average water volume was 1300 m3; it was 1850 m3 for wetgas and 2180 m3 for gas wells. The fracturing treatments were primarily hybrid SW/XL, although some cases used SW/LG/XL. LG was commonly used as a contingency in the transition from SW to XL. Normally, the completion of a Vaca Muerta well involved a total water volume of approximately 6500 m3 for vertical wells and approximately 14 500 m3 for horizontal wells.

Logistics

During the past 5 years, there has been substantial progress related to water management and logistics for sustainable development of Argentina’s shale plays. A variety of water-storage systems and methods for transferring water have been used in the Neuquén basin, primarily in the Vaca Muerta.

Currently, the most common storage systems used are mobile fracture tanks and circular tanks. Pit usage is restricted for environmental reasons.

First Vertical Well

The completion of the first well in Vaca Muerta consisted of four hydraulicfracture stages, requiring of 7600 m3 of water. Alternatives were evaluated for the logistics and water management, and it was decided to install a transfer system through pipes and a water-storage location close to the well to be stimulated. A water well (groundwater with low salinity) in the same field was used for source water. A circular tank for water storage was located in the vicinity. The operator performed the laying of 4-in. pipe from the water well to the water storage location, where two circular tanks were installed.

Vertical and Horizontal Well

The second vertical well in Vaca Muerta consisted of four hydraulic-fracture stages, requiring 8000 m3 of water. For the stimulation of this well, it was decided to drill a new water well close to the wellsite and apply the same water-management strategy.

The first horizontal-well completion consisted of six fracture stages, consuming 13 000 m3 of water. Part of the infrastructure built for the vertical well was used for the horizontal well. Because of the amount of water needed, a new circular tank with greater capacity was required.

Laboratory studies evaluated different alternatives for the use of nontraditional waters as fracturing fluids. The tests included:

1. Detailed water (physical/chemical) analysis

2. Clay-swelling and -inhibition testing

3. Evaluation and development of XL fluids proppant-transport capacity

4. Damage by gel residue and total suspended solids (TSS)

5. Use and Reuse of Flowback,Produced, and Treated Water

Physical/Chemical Analysis. Flowback and produced water have similar characteristics, which differentiate them from fresh water. In general, these waters have higher values of specific gravity, lower pH values, higher levels of total dissolved solids (TDS) and TSS, and significant Ca, Mg, Na, K, Fe, B, and Baconcentrations.

Action as Clay Inhibitor. During the exploration phase of the Vaca Muerta, a routine capillary-suction-time test was performed for each well in a new field; the intention was to understand the degree of water sensitivity and select the best clay stabilizer and concentration.

The following clay stabilizers have been tested and used in these fields:

Quaternary ammonium salt (liquid)

Inorganic salt, KCl (solid)

New ultralow-molecular-weight cationic organic polymer recently applied to replace the quaternary ammonium salts

Fracturing Fluid. Referring to the XL fluid tests performed, the base fluid used was fresh water and the system used guar/borate. The pumping of large volumes of SW or linear gel before an XL gel has a cooling effect, which makes the XL systems subject to background temperatures of approximately 120°F and spacing of approximately 30 to 45 minutes.

Blend of Water (Flowback Untreated). The first test performed used the normal fracturing fluid (guar/borate) with a mixture of waters. The results were not satisfactory because of gel-hydration and -crosslinking problems that resulted in unstable fluids at surface and bottomhole conditions. Moreover, increasing the pH of the system generated filaments, flocculants, and precipitates, although borate systems usually work in high pH.

Treated Water (Flowback). The previously obtained results led to the decision to evaluate the fluid with 100% treated flowback water. Slight changes in pH adjustment and concentration of the crosslinker were made to the fluid.

A reduced viscosity profile was observed between the fluids formulated with blends of water and those formulated with 100% treated flowback water.

Proppant-Transport Capacity. Two types of tests were conducted to analyze transport capacity. The first was a conditional static (settling) test, and the second was under dynamic conditions with a slurry viscometer. The settling test revealed that, overall, the guar/ borate system currently used in operations in the Vaca Muerta lost its carrying capacity after the first 2 hours. The slurry viscometer test indicated that lowpolymer fluid formulations using 100% nontraditional treated water demonstrated good proppant-transport capacity, despite having low viscosity values.

Conclusions

In general, hybrid fracturing-treatment designs dominate the fluid types used in Argentina’s shale plays. The waterstorage systems that have been primarily used are mobile fracturing storage and circular tanks, which are usually at the wellsite being stimulated. Most water is delivered by transport trucks. An integrated water-management plan was developed to support well completions in Vaca Muerta using sources of water close to the wellsite, pipeline transfer systems, and a storage system. For a large scale development, an integrated water management plan must be implemented, taking into account rivers, lakes, water wells, and synergies with other regional operators. Nontraditional water sources analyzed (flowback/produced) for the Vaca Muerta revealed substantial TDS and TSS and significant Ca, Mg, Na, K, Fe, and Ba concentrations. Treating such waters results in important reductions of TSS and Fe.content. The use of these waters in fracture treatments indicated that there is no need to use additional clay stabilizers. A new fracturing fluid, with low polymer loading and low pH, was developed that can be formulated with these waters. This system presents the advantages of working in a range of pH in which precipitates do not generate reduced conductivity in the fracture pack. It generates a good carrying capacity, as seen by settling tests and slurry- viscometer testing. Treatment and reuse of nontraditional water for future fracturing treatments greatly mitigate the issue of freshwater requirements for shale wells and reduce volumes to be injected in disposal wells.

石油圈

石油圈