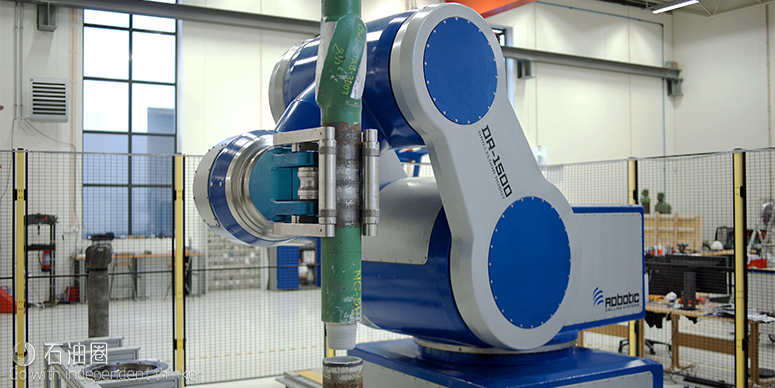

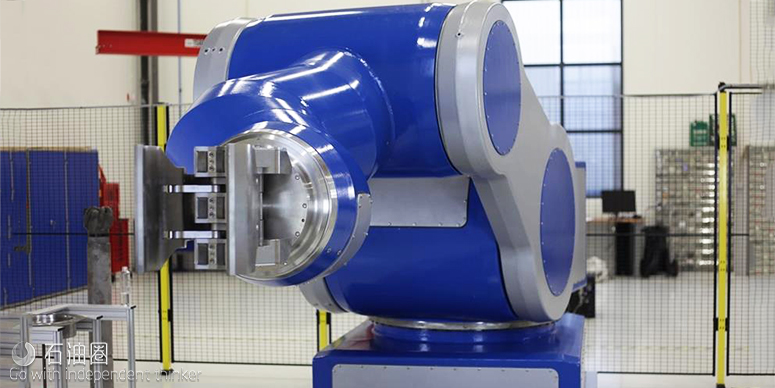

ROBOTIC DRILLING SYSTEM

Robotic Drilling Systems AS (RDS) develops a game changing drill-floor solution consisting of robotic technology for fully unmanned drill floor operations. The system handles pipe and tools and the technology can be applied both on pipe-deck and drill-floor on all drilling structures (new builds and retrofit) for both land and offshore installations.

The robotic control system ensures seamless, fast and precise work operations between the electric drill floor machines. The benefits are faster drilling operations, high safety level due to unmanned operations, and lower installation, maintenance and operations costs.

The drilling industry is discussing more and more that digitalization will be the key factor to get exploration and production prices down to a level that can match the current oil price level. However, in order to introduce digitalization, the industry has to develop the right tools. Digitalization will be hard to obtain with the conventional semi-automated, hydraulic equipment mixed with numerous manual operations. At RDS, we believe that the right tools are precise and flexible, electric robots, which are easy to integrate.

When using the full robotic system from RDS on the drill floor, the robots perform the required work tasks in a fast, seamless, consistent and hands-free manner for improved efficiency and safety.

TECHNOLOGY

RDS is developing a fully electric and robotic drill floor for fast, seamless and human-free operation of pipe and tools on the drill floor. In order to achieve this, three major innovations had to be brought forward:

(1)Electric drill floor machines, such as electric roughneck and electric pipe handler, to allow for precise operation

(2)A dynamic robot control system to allow for flexible operations

(3)A drill floor robot to replace manual operation

The system can be used on new-builds or retro-fitted to existing rigs. In order to achieve a seamless system with good motion control, RDS has replaced the conventional hydraulic drill floor machines with a new generation of electrical machines or robots. In addition to avoiding an HPU, the electric system is easier to install and integrate on the rig. As standard electric motors and gear are used, potentially the reliability will be higher and the energy consumption will be significantly lower for electric robots.

For controlling the robots, a new software platform is developed in order to allow for co-operation between the robots and easy re-programming, if the drilling program suddenly needs to be changed. The commands to the machines are brought to a higher level, where the operator tells the robot WHAT to do (e.g. “insert a new stand”) at not HOW to do it. The robot will program itself on the fly and operate together with the other machines (or robots) through an embedded anti-collision system. The control system allows the robots to operated autonomously, with the options for semi-automatic and remote control, if required in special operations. This will re-define the role of the driller, so that he can focus on the important drilling tasks and not on pipe and tool handling

A high focus area of operators and drilling contractors is to get people out of harms way on the drill floor. Even on high spec rigs, today only the handling of drill pipe is semi-automated and hands-free. As soon as it comes to other types of pipe, such as BHA or casing, or tools and subs, the handling becomes more cumbersome and time-consuming involving manual operations and change-out of handling equipment. With a drill floor robot, with up to 1500 kg handling capacity, the handling of e.g. lifting subs and safety clamps will be fast and safely carried out by the robot.

By introducing a seamless and consistent robotic drill floor system, a number of key drill floor operations will potentially be carried out much faster than with conventional equipment, including:

(1)Tripping (early studies indicate slips-to-slips time of less than 1 minute)

(2)BHA MU/BO and other assemblies

(3)Handling of casing, tubing, liners and screens

(4)Handling of completion components

(5)P&A operations, pick up & lay down drill pipe

Early studies indicate a potential saving of up to 40 rig days per year for a rig (depending on how much of operation time is considered critical), including non-productive time. Several thousands of manual operations will be avoided.

In addition to saved rig time, improved HSE and reduced OPEX, a full robotic system will give other benefits, such as less downtime, faster installation, lower noise, less energy consumption and less CO2 emission.

RDS is in the process of workshop testing the robotic drill floor system including the seamless co-operation between the machines/robots.

In general industry, robots have been used for decades in the manufacturing process. The oil and gas industry has sofar been very conservative.

石油圈

石油圈