Unconventional plays have typically been developed quickly and methodically, giving rise to the term “factory drilling.” But this “factory” or geometric approach to fracturing design overlooks the particularities of each formation and can render 30% of perforation clusters ineffective.

Even a limited dataset—if it’s the right dataset—can make a significant impact on your completion and stimulation programs.

Improve ultimate recovery with maximum efficiency

With a Baker Hughes FracFit™ fracturing optimization solution, you benefit from a “less is more” approach that recognizes significant performance improvements can be achieved without an abundance of data points.

When you choose a FracFit solution, we’ll:

-Identify and collect the most-critical, most-impactful reservoir data;

-Design and help you execute a more-efficient, more-effective stimulation design;

-Minimize project risks and maximize your ROI.

The key is having the right data to truly make informed, actionable decisions. And you need to gather it quickly and efficiently.

With a FracFit solution delivering the right data, you can:

-Target and stimulate the most productive zones;

-Identify and avoid potential geohazards such as water production from nearby aquifers;

-Reduce uncertainty and operational risks like unexpected high treating pressures and screenouts;

-Right-size completion spend and stimulation programs.

The recommended solution may consist of advanced mud logging, LWD, or cased-hole wireline logging, including deep-shear wave measurements capable of characterizing far-field geofeatures. Each of these can work to develop a deep understanding of the reservoir, from which an optimized design is created.

Applications

-Unconventional well completions and stimulations;

-Pre-drilling wells;

-Inventory wells.

Case: FracFit Solution Saved USD 2.5 Million in CAPEX

Challenges

-Risk losing USD 2.5 million investment;

-Drill productive well compared with five offsets that produce only water;

-Avoid complex, uncertain faults to prevent water production from nearby aquifer;

-Determine optimal stage length and natural fracture initiation;

-Control fracture growth toward water-producing zones.

FracFit™ fracturing optimization solution

-XMAC F1 acoustic logging service;

-DSWI processing service;

-Cuttings analysis.

Results

-Saved USD 2.5 million in CAPEX;

-Characterized and navigated reservoir to drill productive well (5 offsets produced only water);

-Mitigated risk of drilling or fracturing into unknown faults;

-Improved completion design by optimizing stage lengths and placement;

-Identified and avoided faults and natural fractures.

An operator working in the Eagle Ford formation of Texas was planning to drill a new well. In preparing to drill, however, challenges began to emerge. A series of complicated and unpredictable faults and natural fractures were dispersed throughout the area, many leading back to a large nearby aquifer. It was essential that the planned well avoid these hazards as five offset wells that had inadvertently tapped into this aquifer were producing only water. If the operator connected with the aquifer, it risked a total loss for the well and its USD 2.5 million investment. However, if the natural fractures could be incorporated into the completion design, enhanced completion efficiency and effectiveness could be realized.

Baker Hughes designed a fit-for-purpose FracFit™ fracturing optimization solution to characterize the lateral, avoid potential water-producing zones, and improve the frac design. FracFit solutions are tailored to the specifics of each formation, designing and executing an efficient, effective, customized stimulation program.

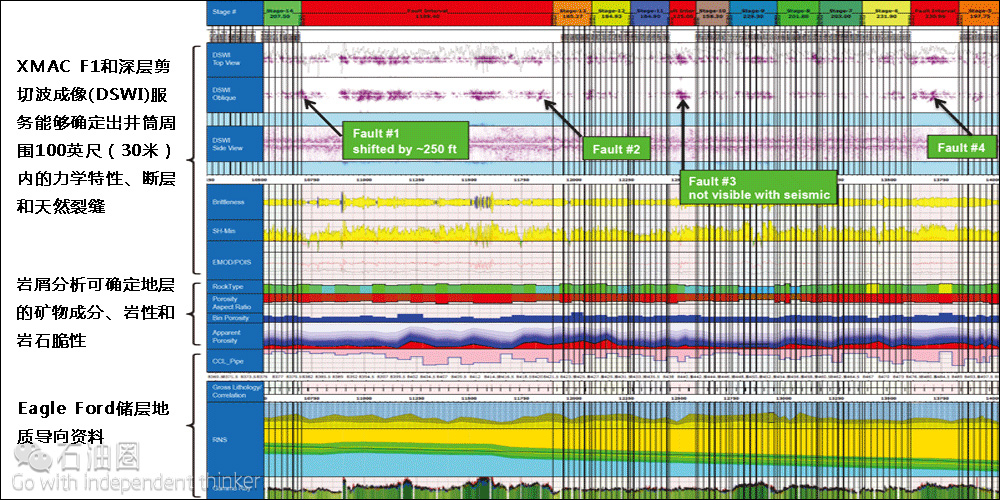

Once the well’s horizontal section was drilled and cased, the XMAC™ F1 acoustic logging service was deployed on wireline as part of the FracFit solution. This service was paired with the deep shear wave imaging (DSWI) processing service to identify geohazards within 100 ft (30 m) of the wellbore and characterize the reservoir’s near-wellbore mechanical properties. The distribution of acoustic reflections and other wave-field attributes were used to build a deep shear wave image. Multiple through-going faults were revealed along the lateral that were potential communication pathways with the underlying aquifer. After identifying these downhole hazards, a multi-stage completion was designed as part of the FracFit solution, the natural fractures were incorporated into the design to obtain equal fracturing initiation for optimal efficiency and effectiveness and maximum reservoir exposure while avoiding all hazards.

The FracFit solution optimized the fracturing design by placing stages away from the faults, targeting natural fractures, and selecting stage lengths by identifying similar reservoir properties.

During the design phase, stage length and perforation placement were tailored by Baker Hughes using the XMAC F1 service’s acoustic information along with cuttings analysis. This combination of measurements helped the operator further reduce the risk of fracturing within the faulted intervals and connecting to the water zone below the well. In a collaborative effort with the operator, the location of faults identified by the DSWI service was confirmed with realtime microseismic monitoring. The operator used this information to make on-the-fly adjustments that would prevent fractures from growing into potential water-producing zones.

The FracFit solution enabled the operator to secure a productive well near a large aquifer. The solution successfully characterized the wellbore and identified faults and natural fractures to be avoided during stimulation, mitigating water inflow to the well. The solution was executed without any NPT or HSE incidents and the operator realized USD 2.5 million in CAPEX savings.

The results of other cases:

1.FracFit Solution Increased Production 45%, Improved Operational Efficiency 60%.

Location: Cleveland Sand Formation, Western Oklahoma.

Results: increased production rates by 45%; improved operational efficiency by 60%; prevented screenouts during fracturing operation; reduced operational NPT.

2.FracFit Solution Increased Barrels-per-foot 44% Over Nearby Offset.

Location: Eagle Ford Shale, Texas.

Results: increased initial production by 44% (bbl/ft) well-over-well; outperformed offset well despite the lateral being 2,000 ft (609 m) shorter; identified high-stress zones, natural fractures, and like-type rock; predicted existence and location of high pressure zones; eliminated risk of screenout.

3.FracFit Solution Increased Gas (68%) and Oil (8%) Production.

Location: Permian Basin.

石油圈

石油圈