GROVE IST Integrated seat technology ball valve

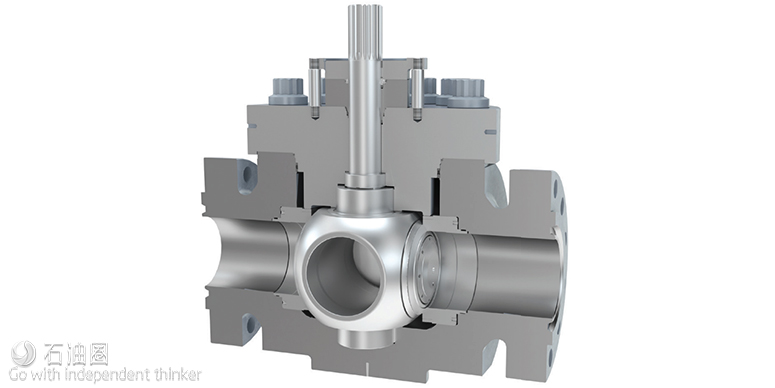

Schlumberger announced today the release of the GROVE IST* integrated seat technology ball valve. New ball valve technology features a patented seat-on-ball design that significantly improves performance over conventional metal-seated ball valves in addition to offering considerable size and weight benefits.

Conventional ball valves tend to become larger in size and weight as oil and gas companies explore harsher environments. The GROVE IST ball valve overcomes these conditions with its game changing seat design that provides advanced sealing performance and increased valve life span while minimizing size and weight, enabling customers to reduce total cost of ownership.

APPLICATIONS

Critical isolation, shutdown, and blowdown service in high-pressure onshore and offshore production facilities

BENEFITS

■Superior sealing performance through patented metal seat

■Space-saving and lightweight design

■Lower torque profile that enables more efficient actuation

FEATURES

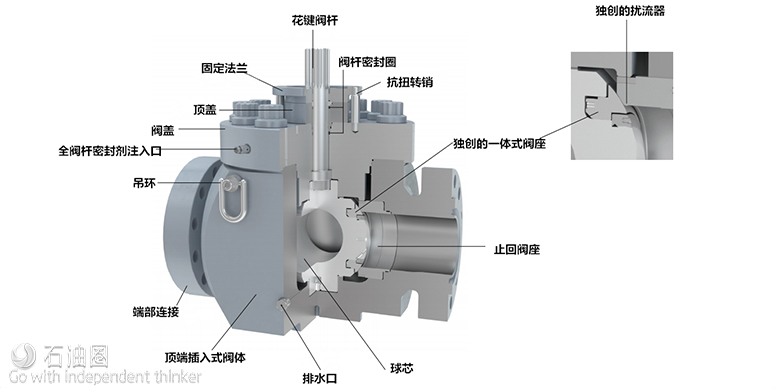

■Patented valve design that overcomes ball flexing and deformation

■Patented flow-diversion spoiler to protect primary sealing elements

■Enhanced sealing capability compared with conventional metal-seated ball valves

■Optimized design using finite-element analysis (FEA) and computational fluid dynamics (CFD)

■Pressure-balanced design for quick closing

■Top-entry body configuration for simplified inline maintenance

■Rigorously tested beyond industry requirements

Operators are driving technical specifications to demand stricter leakage rates for critical service valves. Simultaneously, there is also a need to reduce weight, space, and cost of existing facilities. Manufacturers have responded by pushing the limits of conventional trunnion mounted ball valve technology to achieve the desired results.

With the introduction of the GROVE IST* integrated seat technology ball valve, operators no longer need to use larger and heavier valves to achieve the sealing performance they need. Using patented integrated seat technology, which overcomes ball flexing and deformation at high pressure, the GROVE IST ball valve provides superior sealing performance in a reduced footprint that reduces total cost of ownership.

Reduced costs through lower break-to-open torques

Lower break-to-open torque enables the use of smaller actuation for automated valves. Because of its innovative sealing concept and component geometry, the GROVE IST ball valve requires up to 70%

less torque compared with a conventional metal-seated trunnion ball valve. Lower torques also equate to less wear on moving components.

Consistent superior sealing performance

Industry standards require conventional metal-seated ball valves to achieve ISO 5208 Rate D in liquid or gas performance testing. In contrast, the GROVE IST ball valve consistently achieves ISO 5208 Rate B leakage performance and can be pushed to ISO 5208 Rate A with no visible leakage. This equates to a hundredfold or greater improvement compared with traditional ball valves.

GROVE IST ball valves also include a patented flow-diversion spoiler that protects the primary sealing elements from flow. This leads to reduced erosion of sealing elements and longer field life.

Weight savings from integrated sealing elements

The GROVE IST ball valve weighs up to 40% less compared with conventional valves because its sealing elements are integrated in the ball valve design, delivering a smaller and lighter package (depending on valve size and pressure class). For example, GROVE IST ball valve offers 30% weight savings when compared with a traditional side-entry 71/16-in API 10,000-psi ball valve.

Simple and reduced maintenance

Conventional top-entry valves require special tools to retract the seats and enable the ball to be removed, complicating in situ repair. These tools are often not available, delaying repairs. With GROVE IST ball valves, routine maintenance and replacement of internals are simple and streamlined. Only when installed in vertical piping is a special tool required to support the ball for removal.

Design standards

■API 6D

■API 6A

■ASME B16.34

■ASME VIII

■NACE MR0175/ISO 15156

Certifications

■API 6A PR2

■API 6AV1 (sand slurry)

■API 607 6th Ed. (fire test)

■SIL 3 capability

■PED 2014/68/EU

The GROVE IST ball valve has undergone an extensive qualification test program that qualifies the full product range to API 6A PR2 for performance, API 6AV1 for slurry testing and API 607/6FA for fire testing. In addition, in-line flow testing validation was performed at an independent, accredited testing facility to further simulate real operating conditions.

Design parameters

■Material configurations: carbon steel, low-alloy steel, and corrosion-resistant alloy

■Design temperature limits: –50 to 400 degF [–46 to 204 degC]

■Primary seal type: metal to metal

■Secondary seat seals: elastomer or thermoplastic options available

■Stem seals: elastomer or thermoplastic options available

Critical applications require reliable, high-performing equipment to meet customer needs. Longer life span and a small, lightweight footprint are just as important to maintaining high efficiency and lowering total cost of ownership.

GROVE IST integrated seat technology ball valve meets and exceeds these requirements by offering an evolution of trunnion-mounted ball valve technology. Its patented seat design offers superior sealing performance in a smaller footprint compared with conventional technology.

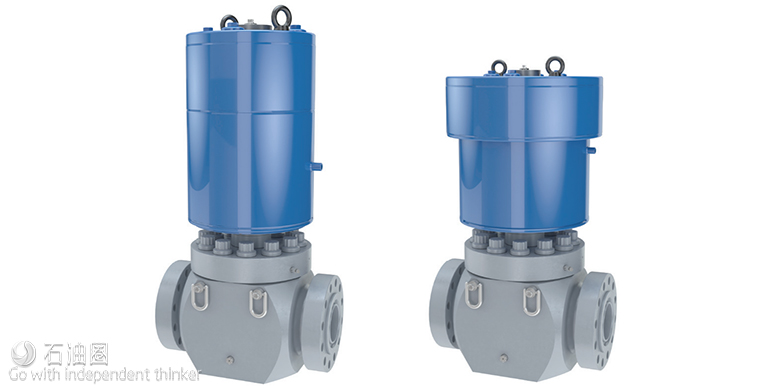

A variety of automation options are available, from gear operators to pneumatic, hydraulic, or electric actuators. Coupling the GROVE IST ball valve with our compact LEDEEN* actuator offering offers further opportunity to reduce space and weight.

Compact LEDEEN HS and CP actuators—some of the smallest actuators available on the market—save valuable space on a production platform or FPSO vessel when installing automated valve packages within the piping system.

Two different torque mechanisms are used, enabling the most appropriate mechanism to be used for maximum efficiency.

For high-pressure hydraulic applications, a small helical spline mechanism is used with a small piston diameter to generate high torque outputs.

For low-pressure pneumatic applications, the larger helical slot mechanism is combined with a larger piston diameter to generate an equivalent torque output.

The compact LEDEEN actuator combined with the GROVE IST ball valve provides a compact and lightweight package that is ideal for critical service applications.

石油圈

石油圈