Service companies use proppants such as raw sand, resin and ceramics during hydraulic fracturing. Proppants are critical because they help keep fractures open and provide permeable conductivity channels back to the well bore. The price varies with each type of proppant. Sand is the cheapest, with resin priced higher and ceramic being the highest priced.

The Oilfield Technology Group (OTG) of Hexion Inc. (Hexion) today announced the release of a new resin coated proppant technology for fracturing service companies and operators in the oil and gas industry.

Putting a resin coating on raw sand increases the strength of the proppant. The coating helps retain the small particles that are generated when enough pressure is applied to crush the sand particles. Fine particles will reduce the conductivity and permeability of the proppant because they will migrate and plug up openings in the proppant bed.

Hexion Inc.’s Oilfield Technology Group (OTG) provides a wide array of innovative proppants designed for a variety of wells. As a global leader in advanced resin technology with years of industry experience, we will help you get the most production out of your well.

Produced water is one of the largest waste streams associated with producing wells and carries a significant cost to the industry. AquaBond-Premium Resin Coated Sand with Stress Bond Technology, it also maintain all the typical advantages of our resin coated sand such as proppant flowback control and enhanced well production.

Description about the AquaBond proppants

AquaBond proppants are one of our latest innovative technology platforms available in 20/40, 30/50, and 40/70 mesh sizes, is a next-generation resin coated sand. These advanced proppants utilize a unique resin chemistry that reduces the production of formation water by altering the relative permeabil of water through the proppant pack, while maintaining oil and gas production.

AquaBond proppants reduced water by 92% without hindering the flow of oil compared to traditional resin coated sand in laboratory testing. This increases the profitability of the well by reducing waste water storage and disposal costs.

Many reservoirs in North America produce a high volume of water with the oil and gas production over the life of the well. Formation water can be caused by issues such as inherent formation characteristics, depleting reservoirs, or EOR (enhanced oil recovery) techniques. Produced water is one of the largest waste streams associated with producing wells and carries a significant cost to the industry.

Along with this unique feature, the AquaBond proppant’s Stress Bond technology delivers all the benefits of a curable resin coated proppant. This includes proppant flowback control, reduction of proppant fines generation, minimization of proppant embedment, and enhanced well production.

“This new resin coated proppant can reduce the production of formation water, but maintains the flow of oil and gas,” said Jody Bevilaqua, President, Epoxy Phenolics and Coatings Division. “The cost savings to operators combined with the enhanced production will help them see even greater returns from their wells.”

Technical advantages and benefits include:

-Reduces the production of formation water while maintaining oil and gas production;

-Minimizes proppant embedment;

-Reduces proppant fines generation and migration;

-Minimizes proppant embedment , helps prevent proppant flowback;

-Stress Bond technology prevents wellbore consolidation;

-Frac fluid and breaker friendly.

Fracture treatments:

-At closure stress up to 10,000 psi [69 MPa];

-At bottom-hole static temperatures from 120 – 450°F [49 – 232°C];

-Vertical and horizontal wells;

-Refracs;

-Any well where water production is an issue.

Technical considerations:

Grain-to-grain contact must occur and closure stress must be applied during the cure period for proper bonding.

-Composition: resin coated frac sand.

-Resin Type: thermosetting, curable.

-Color: light blue.

-Solubility, weight %: in water, brine & HCl: nil; in HCl/HF acid, API RP 19C: ≤ 0.3; in oil: nil.

-Compatibility: Fully compatible with most commonly used fracturing fluids, both water and oilbased systems. Testing with fluids prior to pumping is advised.

-API Mesh Size: 20/40, 30/50, 40/70.

-Physical State: solid granule.

-Specific Gravity: 2.56, 2.55, 2.59.

-Bulk Density: 1.60 [13.4], 1.51 [12.6], 1.46 [12.2]( g/cm3 [lb/gal]).

-Pipe Fill Factor: 0.625 [0.0749], 0.662 [0.0793], 0.685 [0.0821] (cm3/g [gal/lb]).

-Absolute Volume: 0.391 [0.0469], 0.392 [0.0470], 0.386 [0.0463](cm3/g [gal/lb]).

-Median Particle Diameter: 0.6538, 0.4396, 0.3154(mm).

-Particle Size Distribution: meets or exceeds API RP 19C.

-Turbidity, NTU (FTU): ≤ 250.

Product success stories are available for:

East Texas; East Texas/North Louisiana; Permian Basin; Eagle Ford; Rocky Mountains.

The product is also fracturing-fluid and breaker friendly. AquaBond proppants are typically used for fracture treatments at closure stresses up to 10,000 psi and bottomhole static temperatures from 120 to 400°F. They can be used for vertical and horizontal wells along with refractures and any well where water production is an issue.

Resin coated proppants are used in the hydraulic fracturing process to help optimize production from oil and gas wells by maximizing fracture flow capacity from the reservoir to the wellbore. Technological innovations and Hexion’s introduction of enhanced materials have expanded the use of resin coated proppants into unconventional reservoirs that feature complex and challenging geological formations.

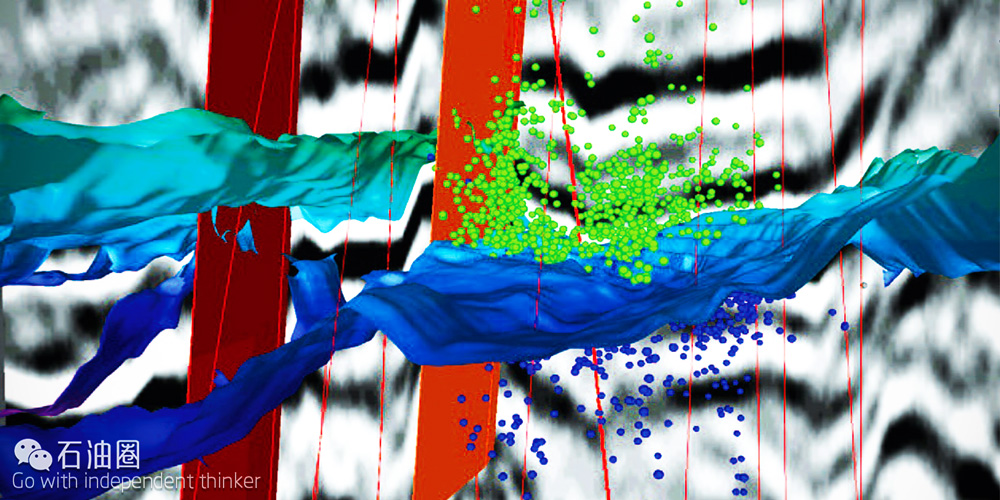

The AquaBond proppant reduces production of formation water. Photo courtesy of Hexion.

U.S. Water scientists test a new product in the research and development laboratory. Photo courtesy of U.S. Water.

About Hexion

Hexion Inc. (Hexion) is the global leader in thermoset resins. Through a broad range of thermoset technologies and specialty products, Hexion serves and supports customers in a diverse range of applications and industries. As a global manufacturer operating approximately 60 industrial facilities around the world, the Epoxy, Phenolic and Coating Resins Division of Hexion is a leading global producer of epoxy specialty resins, modifiers and curing agents serving the automotive, oilfield, electronics, architectural and industrial coatings, paint, packaging, etc.

石油圈

石油圈