CARBOAIR high-transport, ultra low-density ceramic proppant technology has been developed primarily to increase production and EUR from slickwater fracturing operations. The technology enables operators to avoid the introduction of gel into their fracs while improving reservoir contact and fracture conductivity.

CARBO has engineered CARBOAIR technology to have exceptional transport characteristics and significantly more volume per pound. This results in an increased propped fracture height and length to maximize reservoir coverage and contact.

Features

1.Ultra low-density ceramic proppant with chemically-engineered internal porosity

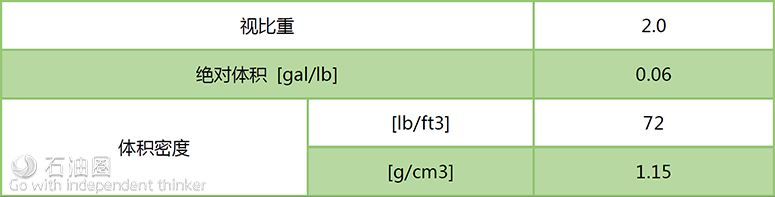

2.Apparent specific gravity of 2.0; approximately 25% lower than sand, resin-coated sand (RCS) or low-density ceramic (LDC)

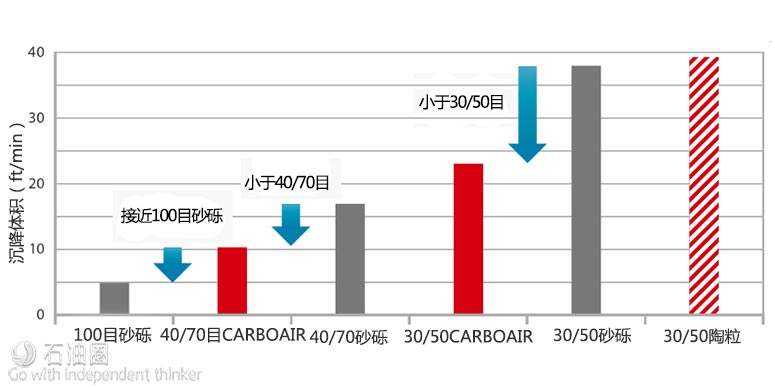

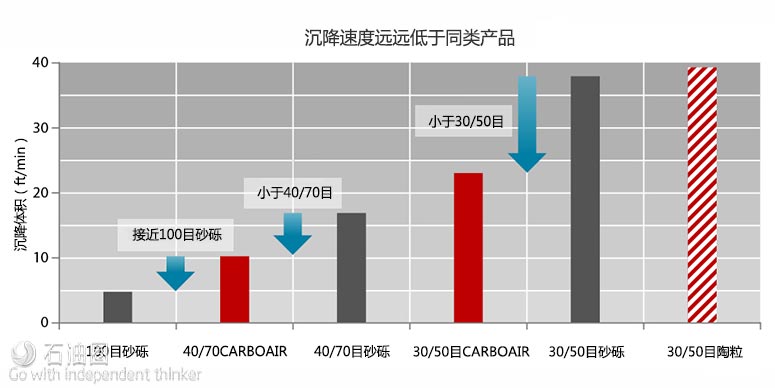

3.Enhanced transport characteristics: 30%–40% slower settling rates compared to sand

4.Meets or exceeds the conductivity, strength and durability of sand and RCS

5.Available in 30/50 and 40/70 mesh sizes

Benefits

1.Exceptional proppant transport in slickwater and low gel fracturing fluids

2.Increases effective fracture length and fracture height to improve reservoir contact

3.Lower total mass of proppant required to prop the same fracture volume as conventional proppant

4.Reduces water consumption and flowback treatment costs in equal volume frac designs

5.Higher production and EUR while lowering finding and development cost per BOE

Exceptional proppant transport characteristics

CARBO has engineered CARBOAIR technology to have exceptional transport characteristics and significantly more volume per pound. This results in an increased propped fracture height and length to maximize reservoir coverage and contact.

The low settling rate of CARBOAIR technology means that fracturing gel concentrations can be reduced or eliminated to avoid gel damage and improve clean-up to further reduce stimulation treatment costs.

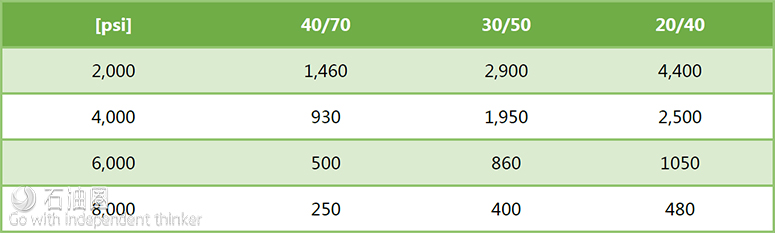

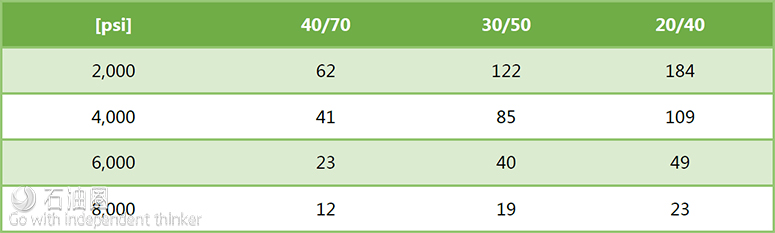

Higher long-term conductivity than sand and RCS

The higher conductivity of CARBOAIR technology compared to sand and RCS along with exceptional proppant transport means that the quality and quantity of reservoir contact is improved.

Achieve higher quality and increased reservoir contact from your AFE

In nearly every reservoir, the higher fracture contact and conductivity delivered by CARBOAIR technology results in higher production and EUR.

Employing CARBOAIR proppant will increase effective fracture contact and can reduce stimulation costs. In an equal volume frac design, CARBOAIR technology requires less proppant mass to achieve the same propped fracture volume as conventional proppant.

The low settling rate of CARBOAIR technology means that fracturing gel concentrations can be reduced or eliminated to avoid gel damage and improve clean-up to further reduce stimulation treatment costs.

Sustains transport and performance characteristics

Proppant with gel coatings designed to improve proppant transport characteristics are continuously stripped of its gel by turbulence and other downhole interactions during the pumping process thereby negating transport and performance benefits. The highly-engineered CARBOAIR technology sustains its consistent proppant transport and physical characteristics, performing as per specifications during the pumping process and throughout the frac.

Outperforms conventional proppant

CARBOAIR technology delivers production, recovery, operational and cost benefits across many different applications.

Improve completion efficiency

Due to the improved contact and conductivity, it is possible to utilize more efficient completion designs with fewer stages or smaller fracture designs to deliver the same or increased production, with no increase in AFE. Any required investment has rapid payback and will result in a lower finding and development cost per BOE.

The advantages of CARBOAIR technology in different applications:

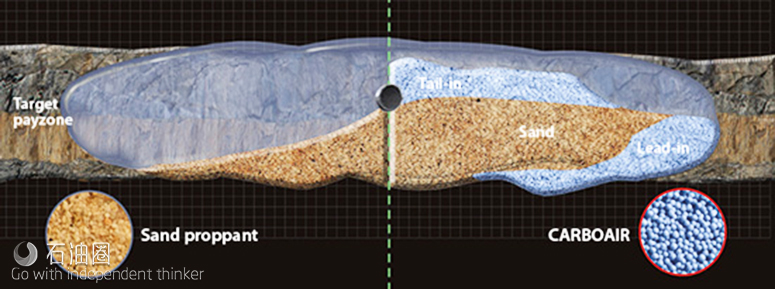

Lead-in/Tail-in with CARBOAIR

As a lead-in, CARBOAIR technology can provide increased propped half length, which increases the drainage area of the fracture. As a tail-in, CARBOAIR technology will cover more of the productive pay zone and lead to increased production compared to conventional sand, RCS or ceramic proppant.

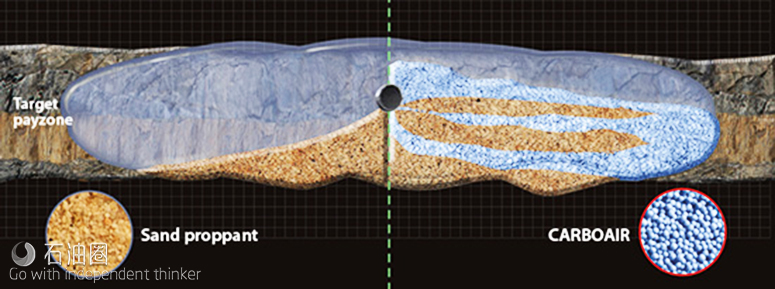

Alternating stages of CARBOAIR and conventional proppant

By alternating CARBOAIR technology with standard proppant within a frac stage using slickwater fluids, the technology can provide increased effective propped length as well as full productive zone coverage, leading to additional production and ultimate recovery.

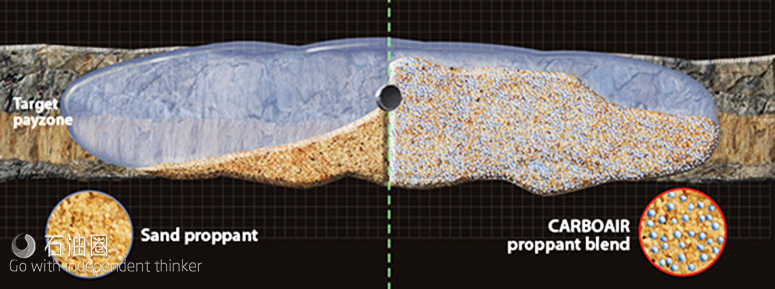

Mixture of CARBOAIR and sand

Blending CARBOAIR technology with sand improves overall proppant transport by hindering the settlement of the sand. This results in increased propped length and height, and pay zone coverage, leading to higher production and recovery.

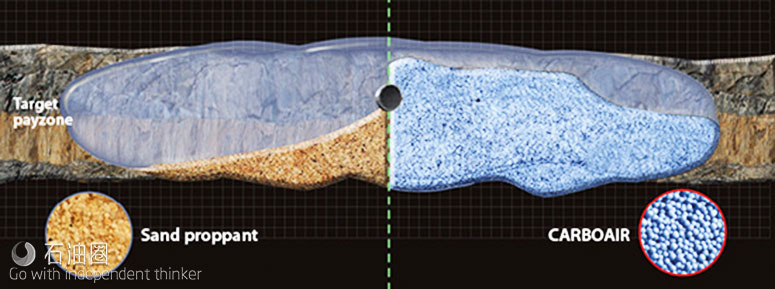

Replace all sand with CARBOAIR

Due to the significantly lower density, 30% less mass of CARBOAIR technology can be used to replace the same volume of sand proppant, thereby reducing the amount of water and chemicals used for the treatment. CARBOAIR technology also provides more coverage across the pay zone, leading to increased production.

Reduce stimulation costs

The lower proppant mass required to achieve the same propped fracture volume with CARBOAIR technology compared to conventional proppant can reduce stimulation costs and the impact of fracturing operations.

1.Less water consumption

2.Less pumping trucks and horsepower

3.Lower flowback treatment costs

4.Reduced environmental impact

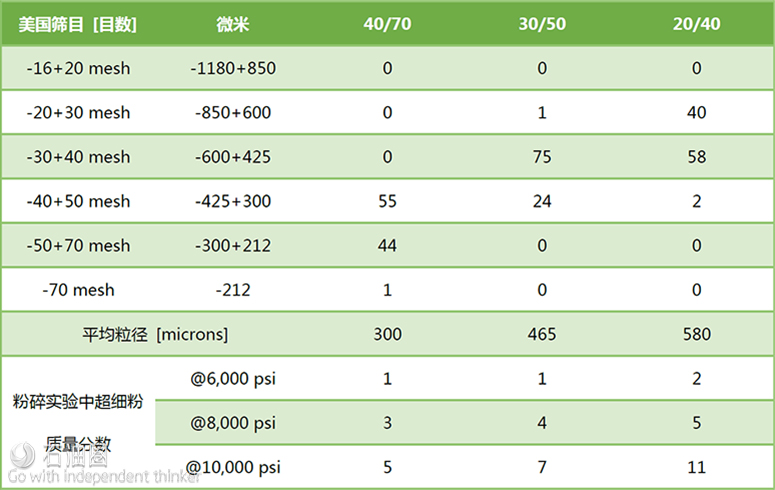

Physical properties

Sizing requirements:

A minimum of 90% of the tested sample should fall between the designated sieve sizes. These specifications meet the recommended practices as detailed in API RP 19C.

石油圈

石油圈