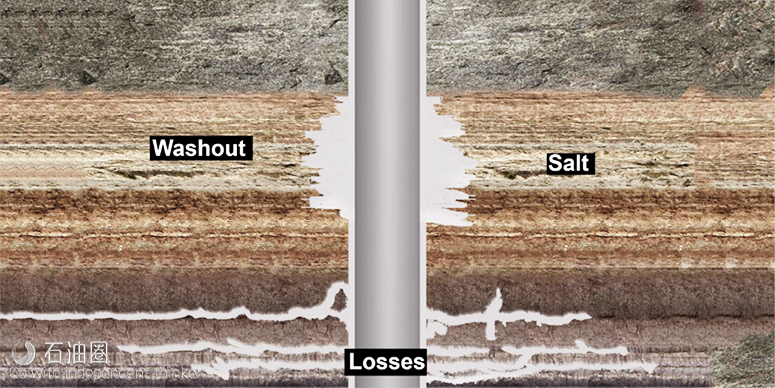

Halliburton’s BaraShale™ Lite Water-based Drilling Fluid is engineered to more efficiently drill in fields that contain salt formations with low fracture gradients. The system contains a proprietary emulsifier that tightly combines the base fluid, which consists of brine to prevent salt washout, and oil to lighten the mud weight. The result is a fluid system that prevents lost circulation and washout while minimizing dilution and waste volumes.

INCREASE DRILLING EFFICIENCY

In addition to the prevention of lost circulation and washout while minimizing dilution and waste volumes, operational efficiency is also enhanced by reducing the need for displacements and enabling mix on the fly instead of batch mixing of the fluid. Field brine can also be used as the base fluid rather than trucking in fresh brine; and unlike other water-based fluids, this fluid can be re-used on multiple wells.

REDUCE COSTS

Not only can the BaraShale Lite fluid system help lower costs through the reduction of downhole losses, salt washout, dilution, and waste volumes, but operators may also be able to change casing designs so that salt sections and lower formations can be drilled together, eliminating the need to run extra casing strings.

MANAGING DRILLING FLUID VOLUMES AND DILUTION

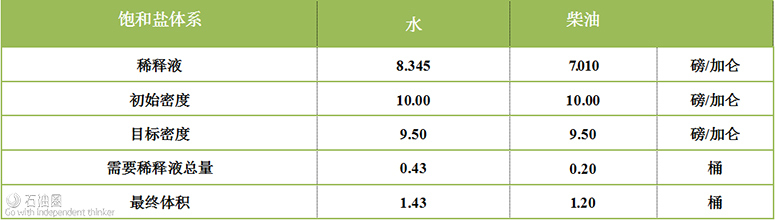

Table 1 below compares the calculated amounts of freshwater and diesel that would be required to cut a 10.0 lb/gal saturated salt brine to a 9.5 lb/gal density. A reduction like this might be required to reduce or eliminate downhole losses in weaker formations. More than twice the volume of freshwater is needed. BaraShale™ Lite can achieve a density below 10.0 lb/gal with salt saturation, and can be used to build stable emulsions which show no hydrocarbon separation after several weeks.

WHY WATER-BASED

A high-performance oil-based mud can be engineered to successfully drill in this environment; however, these systems tend to generate a greater volume of waste which can result in higher disposal costs and higher risks to operators that have to dispose of the cuttings. Water-based drilling fluids can help minimize these waste volumes.

BENEFITS

Helps maximize drilling efficiency

Increases wellbore stability

Increases hole cleaning effiiciency

Increases ROP

Decreases disposal volume for easy handling and safer transport

Cleans up like a standard water-based fluid

Helps Reduce Costs

Reduces downhole losses, salt washout

Re-usable for multiple wells

Requires minimal dilution

FEATURES

Direct Emulsion System

Brine with 10-50% Diesel base

Proprietary emulsifier technology

Straightforward produce mix

Highly maneuverable mud weight

Tolerant of water flows, cement, acid gas, oil-based mud displacement and weight-up

Compatible with water-based/brine chemicals

APPLICATIONS

Intermediate sections

Salt formations and underlying weak, loss- prone formations

Where rapid density reductions may be requi

Case Study

BaraShale™ Lite Fluid Enables Sustained Success of Unconventionals in Low-Cost Oil Environment.

NEW WATER-BASED FLUID SYSTEM HELPS OPERATORS SAVE TIME AND REDUCE COSTS

In the Permian Basin, BaraShale™ Lite system enables operators to reduce total drilling times by 4 to 8 hours.

CHALLENGES

To sustain operations in the Permian Basin against the low-cost oil environment, operators needed to achieve superior borehole integrity and annular isolation, and to reduce drilling time and waste disposal costs.

SOLUTION

BaraShale™ Lite fluid – a new, innovative direct emulsion drilling fluid system delivering greatly improved hole integrity, higher ROPs, and vastly reduced dilution rates

RESULTS

Reduced total drilling time by 4 to 8 hours

Enhanced hole integrity, allowing removal of a casing string while reducing cement volumes and improving zonal isolation

Reduced waste disposal costs by 70 percent

With its unconventional field developments, the outstanding success of the Permian Basin as a global oil and gas swing producer has been sustained by operators and service companies using innovative technologies and cost-efficient operational practices.

Overlying much of the hydrocarbon-rich Delaware Basin – the western province of the Permian Basin – is a thick evaporite sequence posing a significant challenge for wellbore integrity. Commonly used water-based drilling fluids suffer substantially from wellbore washout and from high dump and dilution rates due to salt leaching when drilling through the evaporites. A further drilling hazard has been the frequent occurrence of lost circulation below the evaporite formation because of a reduced formation fracture gradient. Poor hole quality has impacted cementing operations where drilling permits have demanded cement to surface as proof of satisfactory zonal isolation. Moreover, environmental regulations have required waste haul-offs to designated disposal sites where long-distance transportation costs become aggravated by the high dilution volumes.

In the pervading low-cost oil environment, Baroid and its customers identified an opportunity to mitigate challenging operating conditions and costs. In introducing the new BaraShale™ Lite water-based fluid system, Baroid was able to actively demonstrate significant improvements in hole quality, along with a dramatic reduction in lost circulation events and fluid waste volumes. The new direct emulsion drilling fluid system prevented leaching of the evaporitic salt layers, thus maintaining near-gauged hole conditions and removing the need for continuous fluid dilution and dumping. Furthermore, the direct emulsion system facilitated easy management of low fluid densities, enabling successful drilling of formations with very low fracture gradients.

With BaraShale Lite fluid in the hole, Baroid’s customers were able to realize substantial improvements in the efficiency and integrity of cementing operations. Improved hole conditions were demonstrated by caliper logs and by reduced cement volumes and pumping schedules in multiple wells where BaraShale Lite fluid was used. Improved wellbore integrity and the prevention of lost circulation from lower fluid densities allowed the customers to set casing points deeper, thus enabling them to remove a casing string and to substantially improve costs and operational efficiency. Greater rates of penetration (ROPs) with the new direct emulsion system relative to offset wells were also experienced, significantly reducing time to total depth. Further operational gains at the rigsite were realized from a greater efficiency of solids control equipment, as well as from improved cuttings integrity. Salt cuttings were observed for the first time relative to offset operations using conventional water-based drilling fluid systems. The BaraShale Lite fluid provided substantially lower haul-off volumes by preventing salt dissolution.

Baroid’s BaraShale Lite solution allowed its customers to achieve significant cost savings on a well-by-well basis. Total drilling times were reduced by 4 to 8 hours, or 7 percent, compared to offset wells that were drilled in 120 hours, through greater drilling efficiencies gained from simpler drilling fluid maintenance, vastly reduced dilution rates, and higher ROPs. Enhanced hole integrity allowed the removal of a casing string while also reducing cement volumes and greatly improving zonal isolation. Waste disposal costs were reduced by 70 percent due to the significantly lower haul-off volumes with the added benefit of fewer road trips and reduced road safety risks.

The technical and operational success of the BaraShale Lite introduction has been rewarded by increased operator confidence and further work awards for multiple rigs in the Permian Basin.

石油圈

石油圈