DeltaV™ PK Controller

Emerson is launching the DeltaV PK Controller, making the advanced automation of its DeltaV distributed control system (DCS) available to fast-growth industries traditionally less reliant on large-scale automation. The next-gen controller provides scalable automation control to all process industries, particularly parts of the life sciences, oil and gas, petrochemical, and discrete manufacturing industries that have relied on complex, non-integrated programmable logic controllers (PLCs) with limited operational capabilities. The fit-for-purpose DeltaV PK Controller is the process industry’s first controller that manufacturers can scale down for skid units or scale up to be natively merged into the DeltaV DCS in a larger plant.

Today, these industries tend to use PLCs for smaller applications, which can create disconnected “Islands of Automation,” and limits plant production improvements. The DeltaV PK Controller is the first controller to truly bridge small and large control applications. Organizations can leverage the DeltaV PK Controller for effective, easy-to-implement standalone automation control akin to a PLC but with the features of a full-scale DCS, including advanced batch production, recipe management, execution, and historization. Users can then choose to leave the DeltaV PK Controller standalone, or natively merge it into their DeltaV DCS. This capability eliminates operational complexity and dramatically improves the performance, safety, and efficiency of their entire project and operational lifecycle.

The DeltaV PK Controller is the latest addition to Emerson’s Project Certainty initiative, targeting radical transformation in capital project execution. The new controller will simplify capital projects by enabling OEM skid-builders to design and produce skids in the same way they do today, while eliminating the costs, time, and risks associated with integrating a PLC into their control system.

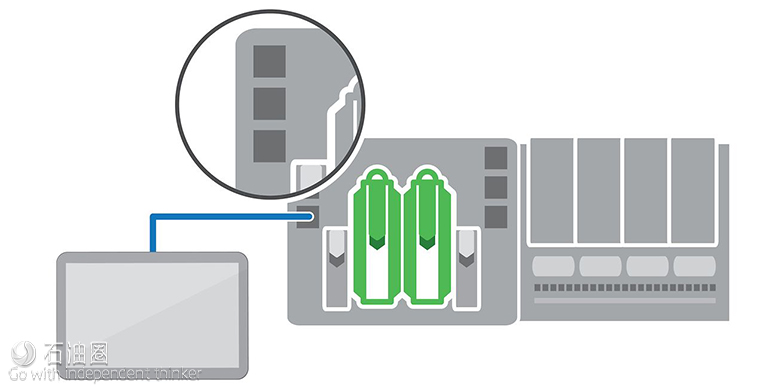

The DeltaV PK Controller was designed from the start with connectivity, particularly into the IIoT, in mind. The scalable controller leverages an assortment of communication protocols, including the first Emerson controller with a built-in OPC UA server. It is also the first Emerson controller with six Ethernet ports and can operate using any Emerson DeltaV I/O type, including DeltaV Electronic Marshalling, traditional marshalled I/O, wireless I/O, and integrated safety instrumented systems. In addition, it has built-in protocols to communicate with Ethernet devices such as drives and motors. Together, these features make connectivity easier at every stage and help plants achieve operational benefits of cloud-based tools and analytics through the IIoT. The DeltaV PK Controller also features built-in redundancy for controllers, communication, and power supplies, allowing organizations to improve uptime without adding to complexity or footprint.

The DeltaV PK Controller brings faster logic execution, built-in native Ethernet device protocols, and many scalable sizes, enabling it to address a wide variety of applications such as Ethernet device control, wellpads, and a wide variety of system sizes. From small-scale applications like skid-units, to your large-scale traditional control operations, the multi-purpose, multi-functional controller can handle your toughest demands no matter the size or stage of your operation.

Specifications

DST Limit 100, 300, 750, or 1500

Module Execution Rates 25ms, 50ms, 100ms, 500ms, 1s, 2s, 5s, 10s, 30s, 60s

User Memory Controller memory, SD-Card memory

Input Power Required 24V DC

Protocols Supported Natively on PK Controller Modbus TCP (Server & Client), Ethernet/IP (Client: Class 1 & Class 3), and OPC UA Server. Other protocols available through dedicated Bussed cards

Operating Temperature -40° to 60°C (-40° to 140°F)

Storage Temperature -40° to 85°C (-40° to 185°F)

Relative Humidity 5 to 95%, non-condensing Protection Rating IP20, NEMA 12

Airborne Contaminants ISA-S71.04-1985 Airborne Contaminants Class G3 Conformal Coating Shock (Normal Operating Conditions) 10g ½-sine wave for 11ms

Vibration (Operative Limit) 1mm peak-to-peak from 5Hz to 13.2Hz, 0.7g from 13.2Hz to 150Hz

Features

Runs standalone or as part of a DeltaV system

Seamlessly merge into a DeltaV system resulting in one native database and system

Eliminates the cost and time-consuming data mapping exercises

Saves cabinet space by leveraging the six built-in Ethernet ports

Supports 1:1 redundancy without adding footprint or configuration changes

Flexible I/O enables you to choose from M-series traditional, S-series traditional Charms I/O Card and Wireless I/O cards to best suit your needs

Integrated safety with DeltaV SIS Electronic Marshalling and DeltaV SlS 1508 Safety Logic Solver

Easily connect third-party devices such as Panel HMIs and variable speed drives natively without the use of a dedicated Ethernet or I/O card.

Get secured access through added layers of protection and encryption technologies that prevent against unauthorized access

Faster logic execution capabilities

Retains configuration for 18 months without power

石油圈

石油圈