A TURNING POINT FOR TUBULAR RUNNING

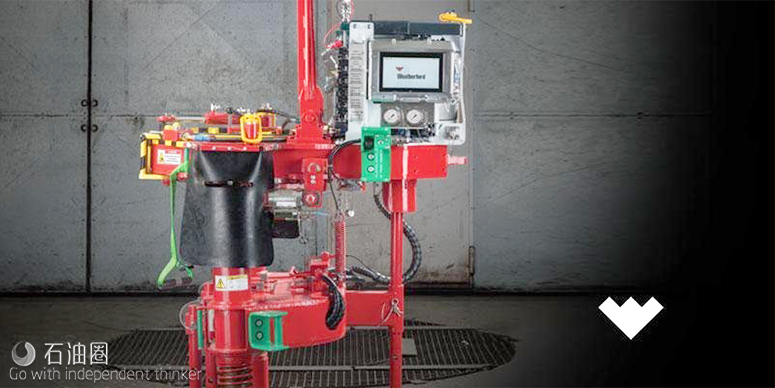

Weatherford International plc today announced the commercial release of the AutoTong system featuring AutoEvaluate connection-makeup software. The AutoTong system is the world’s first technology to automate pipe makeup and to provide autonomous connection evaluation.

Using the AutoTong system, the final pipe-makeup process is initiated with the push of a button. The system autonomously determines the appropriate connection parameters based on the pipe and thread criteria specified by the original equipment manufacturer. Providing complete control throughout the final makeup sequence, the system continuously monitors the torque and adjusts the rotational speed of the casing to achieve the optimal torque value. The integrated AutoEvaluate software automatically evaluates the connection quality based on high-resolution data and does not require a joint-makeup analyst to interpret the data.

“By eliminating the element of human error from the physical makeup and connection validation processes, the AutoTong system sharply increases the safety and efficiency of well construction operations,” said Aaron Sinnott, V.P. of well integrity at Weatherford. “The addition of automation to the makeup process represents a real turning point for tubular management.”

Transform the makeup process by adding automation to your operations

Automation is the answer. The same advancements made to automate manufacturing and other industries are now being applied in the oilfield. Intelligent machines take over repetitive manual work so that you eliminate human influences and create a better well. In tubular running, automating the right equipment or process can result in significant time savings, cost benefits, and safety enhancements.

The Weatherford AutoTong™ system—with AutoEvaluate™ software—heralds a historic turning

point for connection integrity. This first-of-its kind system automatically makes up pipe and autonomously evaluates connections for enhanced efficiency and reliability. With computer-regulated makeup and built-in evaluation, you can reduce human influences, increase efficiencies, and validate integrity without question.

AutoTong™ System Advantages

(1)Automates makeup using precise, consistent control

Experience more efficient operations, hands down. With just a single click, the operator initiates the final makeup process. The system takes control of the procedure with mechanical precision. For each connection, the system uses a proprietary speed-control algorithm to maintain consistency and repeatability.

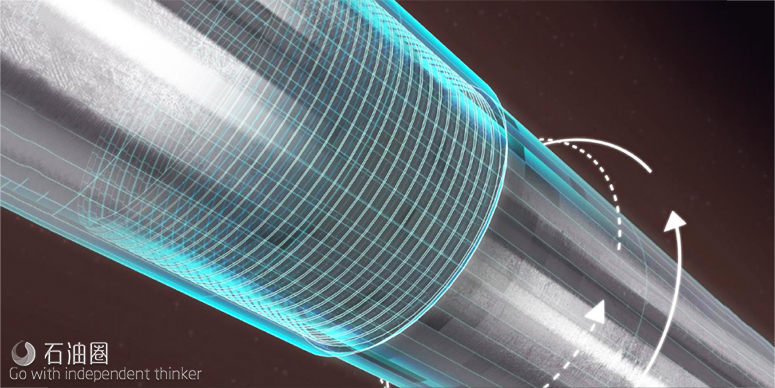

(2)Evaluates connections with indisputable accuracy

When it comes to connection integrity, mistakes are unacceptable. Wellsite field personnel can unintentionally influence conventional connection acceptance verification. Our AutoEvaluate software provides objective interpretation of 10 times more data points that the human eye can see, which removes gray areas for verified connection integrity.

(3)Reduces rig-up time with easy installation

Installing our automated system means one and done. The all-in-one AutoTong system comes complete with components and software for one-step installation, which cuts down on lost time and costs. By comparison, conventional makeup involves multiple individual components that require connectivity for both hardware and software communication.

(4)Minimizes manual entry using prepopulated data

Run optimal connections without fail. Inputting incorrect data can result in overtorqued or undertorqued pipe, which can lead to potentially catastrophic connection failures. Our automated system standardizes inputs to eliminate erroneous entry. Then you can build well integrity connection by connection.

JAM Cloud Data Storage

Our cloud storage houses data— from the pipe mill, offline makeup facilities, and wellsite—in

one place and in sequential order. It provides remote, secure access to historical and real-time

information and enables building a wellness report for every connection.

AutoEvaluate™ Connection Makeup Software

Fully integrated with the AutoTong system, our software improves operational consistency, efficiency, and safety. After the controlled makeup process, the software uses high resolution data to automatically evaluate connection makeup in real time. automate speed control, achieve the target torque, and eliminate human inaccuracies.

石油圈

石油圈