The EcoStar valve is the world’s first electric tubing-retrievable safety valve (e-TRSV) developed in collaboration with TOTAL. It eliminates hydraulic fluid to enable a fully electric completion system and minimizing the risk of exposing electronics to produced wellbore fluids while retaining the same safety mechanism as today’s conventional safety valves. The EcoStar e-TRSV provides direct positional feedback between the full open and full closed positions, and includes sensor communication back to the surface, which allows for analysis and diagnostic capabilities that are not available in any other safety valve today.

Artie Burke, vice president of the Halliburton Completion Tools business line said, “We are thrilled that the EcoStar e-TRSV has won this prestigious award. In addition to its safety benefits, switching a subsea project from hydraulic to all-electric functionality by using the EcoStar e-TRSV can save as much as 40% on CAPEX. The EcoStar e-TRSV was installed for TOTAL in 2016 in an all-electric control system, and we envision it enabling frontier developments in deep water in the years to come.”

OVERVIEW

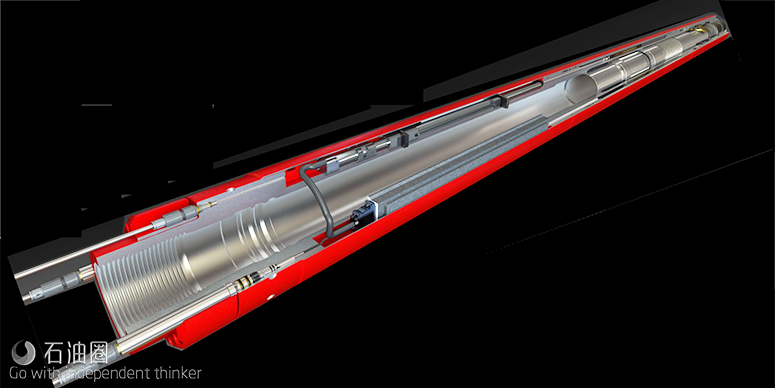

The Halliburton EcoStar™ valve is the world’s first electric tubing-retrievable safety valve (e-TRSV). The EcoStar e-TRSV solves a 30-year industry challenge to remove hydraulic actuation and its limitations from the picture. The constraints of hydrostatics and fluid friction required to close a valve quickly in the event of an

emergency, and the distance from point of control to the subsea wellhead, are removed. This enables a fully electric completion system with zero risk of exposing electronics to produced wellbore fluids and the added benefit of also serving as a conventional safety valve with the same trusted failsafe mechanisms.

This breakthrough in electric actuation is made possible through a unique coupling mechanism between the actuator and the safety valve. The design and construction of the valve creates a chamber for the downhole electronics and electric actuator outside of the wellbore, completely isolating them from well pressure and the detrimental effects of wellbore fluids. This makes it possible for operators to experience life-of-the-well reliability in electronics, a mandatory requirement for safety valve applications. In addition, the EcoStar e-TRSV provides direct positional feedback between the full-open and full-closed positions, and includes sensor communication back to the surface. This data allows for analysis and diagnostic capabilities that are not available in any other safety valve today.

The EcoStar e-DHSV eliminates the requirement for hydraulic umbilicals, providing the potential to reduce CAPEX and OPEX in more complex field developments. The EcoStar e-TRSV also helps eliminate potential environmental impacts due to loss or spills of

control fluids over the long-term field life.

FEATURES

» All-electric actuation

» Mechanical failsafe closed

» Redundant actuation and control systems

» Sensing and reporting of valve position and

electronics

BENEFITS

» Operational challenges

• Water depth boundaries are increasing

• Longer step outs and remote operation

from base

– Electric operation provides answers to

these challenges

» Environmental stewardship

• Increasing regulatory framework

• Ecologically sensitive locations

– Zero possibility of hydraulic discharge

» Field development economics

• All-electric systems have the potential to

reduce CAPEX and OPEX

石油圈

石油圈