The oil and gas industry is increasingly challenged by enormous financial stakes, exacting operational requirements, and concern for human safety and the environment. Many of these risks arise from an inability to accurately, efficiently, and safely visualize the downhole well environment and characterize the reservoir and its reserves.

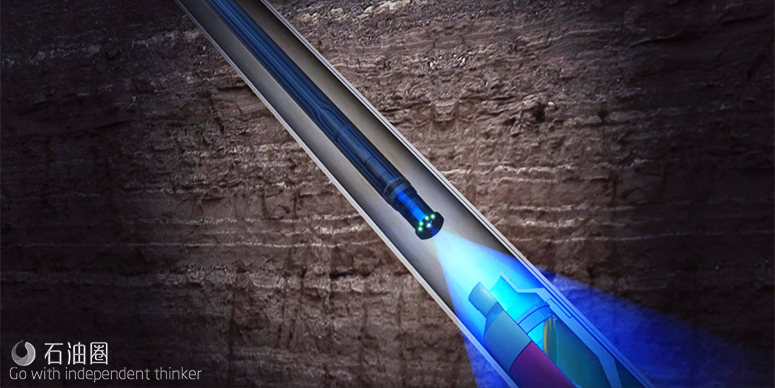

Visuray has responded to these challenges by being the first and only company to develop a game-changing Downhole X-Ray Platform. The platform has taken over 10 years to develop, and is protected by multiple patents. It provides the foundation for a new generation of downhole tools that offers oil companies increased safety, superior environmental performance, and reduced operational risk.

HOW IT WORKS

The Visuray Downhole X-Ray Platform uses X-ray scattering to produce clear images within the downhole environment. X-ray backscattering occurs primarily in the fluid, and any scattering due to an object in the fluid is negligible. This means that backscatter technology can work in any borehole fluid. X-ray foward scattering is very sensitive to the density of the material it passes through. Since the X-ray source is several orders of magnitude brighter than conventional radioisotopes, forward scatter technology can be used to precisely probe the well environment through multiple casings.

Wherever the well and whatever its condition, the Downhole X-Ray Platform’s family of services will see what’s happening and deliver quality images 100% of the time.

CHALLENGE CONVENTION

Five distinct technological developments and innovations lie at the heart of the Visuray platform. First is a range of custom-designed photon counting X-ray detectors which include dense, pixelated arrays derived from technology developed in the medical industry, and customized compact photomultiplier/scintillator detectors that have been in use in the oil industry. Second is a range of powerful X-ray sources that have been specially miniaturized and designed for high output. This is driven by the third Visuray innovation – a compact, ultra-high voltage power supply enabling the source to emit high-energy X-rays. Fourth, is a family of heat exchangers and active downhole coolers used to maintain the temperature of sources and/or detectors within acceptable limits. The last innovation provides patented data analysis and processing techniques that convert the acquired digital data into 2D and 3D inversions and/or reconstructions.

VR90

The first tool, known as the VR90 downhole X-ray diagnostic tool, entered commercial service in 2015 and has already demonstrated value in a variety of well inspection operations for customers in Northern Europe, the Middle East, and the United States.

VR90S

Following the successful launch of the VR90 downhole X-ray diagnostic tool in 2015, Visuray has developed an improved version of the tool known as the VR90s advanced diagnostic tool. The VR90s tool is the second product offering from the Visuray Downhole X-Ray platform family.

The VR90s tool is rated to the higher temperature of 125°C and is available in a slimmer 3 3/8-in. housing. The tool offers enhanced measurement capability with millimetric scanning of zones of interest for closer diagnosis of in-well details, debris, or damage. This ability is further enhanced by a wider field of view for more complete imaging of target objects. Combined with an integrated positioning module, the VR90s tool can be precisely positioned within the well. Compliance with NACE MR0175 / ISO 15156 also primes the VR90s tool for service in sour wells.

The VR90s tool has been tested and is now commercially available.

‘The VR90 downhole X-ray diagnostic service has a great track record in providing our customers with accurate and unambiguous answers, but the enhanced capabilities of the VR90s tool meet a greater range of client needs,’ said Kambiz Safinya, Visuray’s Group CEO. ‘We are excited to offer this new service that will provide our clients improved images in problem wells, however opaque the downhole environment.’

Benefits

Higher temperature rating: Rated to 125°C

• Integrated positioning module: Precise tool placement

• Slimmer outer diameter: Entry into a wider range of wells

• H2S rated: Compliant with NACE MR0175 / ISO 15156

APPLICATIONS

INSPECTION

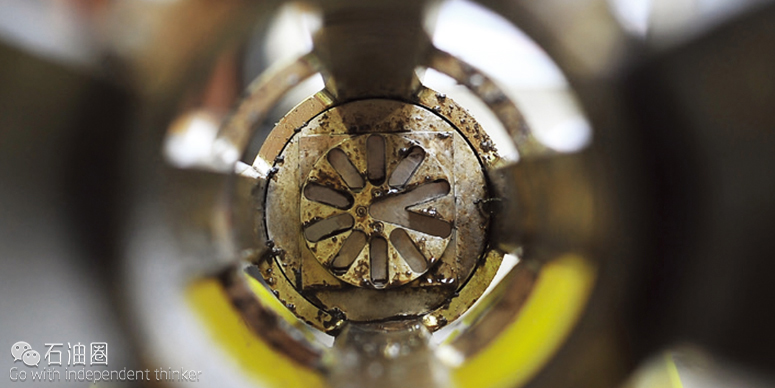

• SSVs, flapper valves

• Y-tools, ball valves

• Well obstructions

• Milling operations

• Whipstock evaluation

FISHING / RETRIEVING

• Fish inspection

• Plugs, packers, etc.

• Casing / tubing

• Cable fishing

• Dropped objects – identification, position

VR360

Coming next will be the VR360 diagnostic cement evaluation tool, which radiates X-ray photons radially outward from the tool axis to directly evaluate cement integrity and detect mechanical anomalies, even in double casing strings. It is designed to provide the needed step change in the evaluation of well integrity, not only in new wells with advanced cements but also in the increasingly important market for the decommissioning and abandonment of older wells.

The VR360 diagnostic cement evaluation tool is designed to provide a needed step change in the evaluation of well integrity. This second-generation Visuray technology radiates X-ray photons radially outward from the tool axis to directly evaluate cement integrity and detect mechanical anomalies, even in double casing strings.

The VR360 service overcomes many of the limitations of current cement evaluation technology. It is the first direct measurement of cement distribution with its ability to evaluate even the most advanced, lightweight oilwell cements, thereby making it superior to current ultrasonic technology. While regulatory focus on deepwater well integrity initially stimulated this development of the Visuray Downhole X-Ray Platform, a similar focus on the abandonment of wells in old fields has opened a new and important market for the service.

Significant industry funding has already been secured to accelerate the commercial development of the technology. Key milestones in its technical development have also been reached with full-scale tests in realistic single- and dual-casing well environments, proving the tool’s ability to directly evaluate cement distribution and determine mechanical integrity.

石油圈

石油圈