German oil and gas company Wintershall is engaged in a research project exploring the use of the fungus Schizophyllum commune in polymer flooding.

The fungus produces abiopolymer, schizophyllan, that researchers say tolerates high temperatures, maintains good mechanical stability and is fully biodegradable.

The technology could be an effective enhanced oil recovery (EOR) tool in certain reservoir conditions, says Klaus Langemann, head of technology at Wintershall.

“Biopolymers tend to have a much higher stability towards challenging reservoir conditions such as high temperature and high salinity,” Langemann says.

“Chemically derived polymers typically don’t show this stability, and show mechanical degradation under shear stress.”

“Most of the world’s oil reserves are located in the Middle East, where such conditions prevail.”

“Biopolymers tend to have a much higher stability towards challenging reservoir conditions such as high temperature and high salinity.”

—Klaus Langemann, Wintershall

“So, we believe the potential for chemical EOR using various methods in the Middle East is very significant, and that’s why we focus our efforts there.”

“Another advantage is of course the environmental benefit of a biopolymer, especially when it comes to disposal of the re-produced EOR fluid.”

Polymer flooding is a chemical EOR method in which a thickening agent is added to water to create a more viscous fluid.

The viscosified water is injected into the oil reservoir to push more oil to the producing wells.

“The effectiveness of polymer flooding mainly depends on the viscosity of oil to be displaced,”Langemann says.

“Very light oil with viscosity close to water is not suitable for a polymer flood because the effect on oil displacement is negligible. Heavier oils, however, show a much better displacement.”

Operators favour chemical EOR because it makes use of existing field infrastructure such as wells and oil-water separation systems, and therefore limits capital expenditure — an important driver in todays market, he says.

Natural solution

Wintershall says schizophyllan could prove to be a truly valuable discovery for crude oil production due to its tolerance for high temperatures and heavy salt concentration.

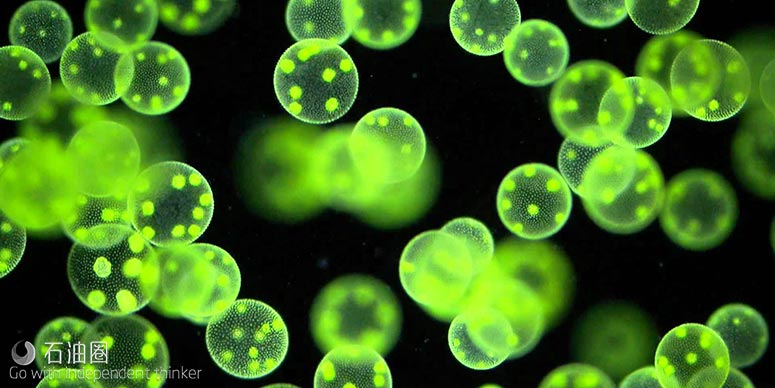

The company says the biopolymer could increase recovery rates by about 10%.The fungus is found on dead wood in coniferous and deciduous forests, feeding on oxygen and carbon sources such as sugar.

As it grows, it generates a biopolymer used to develop its own cell walls.

Wintershall parent company BASF produces the schizophyllan thickening agent exclusively for the oil company at an expanded biotechnology plant in Ludwigshafen, Germany.

The companies have been testing the technology for years in the Bockstedt field in the north of the country and are confident that the biopolymer can be controlled under reservoir conditions, Langemann says.

The polymer is mixed with reservoir water and a preservative to protect the schizophyllan from bacteria.

The solution contains roughly 0.03% biopolymer, enough to thicken the water by a factor of 25.

Any future application would be subject to the general guidelines Wintershall employs for EOR projects, Langemann says.

“In order to plan and execute an EOR project, we have established a specific work flow. In a primary screening, the oilfield under consideration is analysed in detail for potentially relevant EOR methods.”

“If chemical EOR is identified as a viable method, chemical formulations are developed and tested and optimised in the interaction with reservoir fluid — oil and brine — as well as with reservoir rock.”

“If laboratory investigations show significant additional oil recoveries from reservoir rock samples, the findings are being transferred to field level.”

“Typically, initial field test are single-well tests — huff n puff — to test injectivity and stability of the injection fluid.”

“If successful, additional oil recovery is proven at field level via a multi-well test, where the chemical formulation is injected into the reservoir via an injection well and additional oil is detected at one or more producing wells.”

“Once this is achieved, the chemical EOR is further applied at larger portions of the oilfield.”

“We always select the most promising EOR method for a given reservoir.”

Chemical EOR includes more than polymer flooding, Langemann points out. “We also develop surfactant and microbial EOR technologies.”

Regarding the latter, he says, “our approach here is to feed certain micro-organisms that are naturally present in the reservoir with tailor-made nutrients.

“The growth and metabolism of these micro-organisms then trigger several EOR effects in the reservoir, like conformance control, wettability change and reduction of interfacial tension.”

“The striking feature of microbial EOR is the use of environmentally benign nutrients to feed the micro-organisms.”

Chemical EOR, he says, “is a very complex technology where all components of the EOR value chain, ranging from subsurface assessment and modelling, chemical formulation and upscaling, core flooding techniques, logistics and field application design and execution have to be well orchestrated for an EOR project to be successful.”

“It is key to integrate all relevant disciplines into one team in order not to lose any important information.”

The company’s relationship within the BASF Group, and its ability to “provide all components of that EOR value chain”, gives Wintershall an advantage at its operated assets and as a valuable partner in other oilfields, he says.

“In any case, implementation of EOR technologies at an early stage of the lifecycle of an oilfield and consideration of a later EOR scheme already in the initial field development plan promises the highest value creation.”

Wintershall’s future goal is “to deliver technological solutions that enhance the value of our assets”,Langemann says.

“The use of a fungus could be one of them. But an extraordinary and challenging one. That is why the company plans to extend schizophyllan trials to other oilfields, including offshore projects.”

石油圈

石油圈