Optimizing Production, Economics In Mature Fields

To generate cash flow in low-price markets, operators have historically turned to the resource they can count on most—fields that have proved they can produce. But optimizing production from mature fields presents its own set of challenges that have the potential to offset the benefits of improved production with higher capital expense. Increasing production while lowering lifting costs and total cost of ownership requires not only reversing declining production rates but also doing so with the highest levels of efficiency.

A series of new chemicals for near-wellbore damage (CND) from Baker Hughes has demonstrated the ability to remediate wellbore and near-wellbore damage from multiple mechanisms in a single time-saving treatment and to restore shut-in wells to productive life. The CND remediation treatments are made from custom-formulated microemulsions that remove existing damage and leave the formation surfaces waterwet for easier and faster production. The chemicals can be used in mature fields, gas storage wells, production and injection wells, and disposal wells.

Damage mechanisms

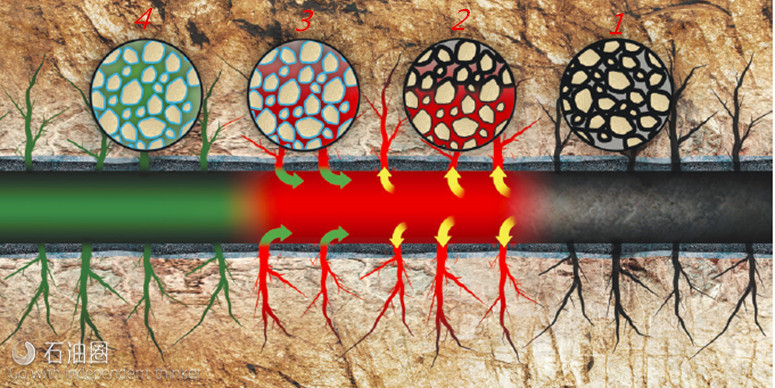

Over the lifetime of a well, scale deposits, paraffin and asphaltene deposits; sludge; fines; emulsions; oil-wet solids; and microbial slime can build up in the near-wellbore area of openhole wells or anywhere from 0 in. to 24 in. from the perforations that serve as conduits from the reservoir into a cased-hole well. Often these deposits build up to the point of causing formation blockages, or skin, that can restrict the flow of fluids and gases from the reservoir and reduce productivity.

Standard industry practices to remediate near-wellbore damage have historically involved solvent washing, acid treatments and hot oiling/watering, which typically deliver short-term production improvement. Many solvents can remove hydrocarbon deposits, but they leave the rock surfaces oil-wet, which is another type of damage, and also could leave the heavy hydrocarbon deposits to become more problematic and complex to remove as the well matures. While acid treatments are effective at removing inorganic carbonate scale, they can cause asphaltene molecules to destabilize, which leads to future organic damage. Similarly, hot oiling and watering techniques help lower the viscosity of paraffin. But as the waxy fluid flows deeper into the reservoir, it cools and creates blockages in other areas.

Wettability

Another challenge to optimizing production from mature fields is formation wettability. Wettability is the ability of a fluid to maintain contact with a solid surface in the presence of other fluids. A good example of wettability at work is liquid car wax. The liquid wax is spread over the surface of the car. When a drop of nonwetting fluid— rain—hits the waxed surface, the rain will bead up, minimizing its contact with the surface of the car. The normal state of sandstone formation rock is water-wet. This is what causes the oil to move into the wellbore rather than adhering to the rock. Water-wet reservoirs are changed by the adsorption or deposition of organic deposits such as asphaltenes or paraffins. The wettability of formation rock also can be altered by surface-active additives used during wellbore construction or in well interventions.

Single-treatment solution

Operators have long sought an economical solution to repair near-wellbore damage and increase production or injection rates without adverse side effects caused by many traditional stimulation methods. CND chemical remediation programs designed to treat single damage mechanisms were introduced several years ago. More recently, three new microemulsion products were released to remediate multiple damage mechanisms in a single-step treatment. The multifunctional microemulsions consist of a solvent, co-solvent, an aqueous phase and surfactants. The microemulsion fluid formulations were specifically designed to provide production stimulation in wells damaged by a combination of factors. These treatment products can be combined with acids to dissolve scale buildup and remove organic deposits in one step.

The CND500, CND600 and CND700 multifunctional CND treatments are designed to target, disperse and remove the main mechanisms of formation damage. The CND600 product focuses more heavily on organic deposit damage. The CND700 product has a high flashpoint, making it particularly applicable to offshore applications.

By using multifunctional remediation treatment, the possibility of misapplications and negative results is minimized. The remediation treatments remove skin damage and clean the near-wellbore area, water-wet the formation, restore fluid communication, and preferentially remove deposits from oil zones. The treatments require no additional equipment for application, so large capex investment is avoided.

Generally, these remediation product treatments require 100 gal to 5,000 gal—4.5 gal to 6 gal per meter (15 gal to 20 gal per foot) of perforation—depending on the number of feet of perforations, downhole pressure and the extent of the skin damage. The product is applied directly down the annulus or down the production tubing of the well with the well production shut in. The treatment is allowed to contact the damaged formation area for 24 hours prior to the re-initiation of production. During the 24-hr soak period, the selected CND microemulsion disperses organic-based skin damage, breaks emulsion and water blocks, and cleans the tubing and flowline spontaneously. The treatment also water-wets the formation. The straightforward removal process is more rapid and efficient than other stimulation methods .

The primary properties of the CND products are ultralow interfacial tension, high oil solubilization and high water-wetting of solids surfaces, often restoring permeability to greater than 100%. Ultralow interfacial tension of CND treatment means that no mechanical energy is required for cleaning. High solubilization enables the treatments to remove oil and to break emulsions and sludge. Wettability reversal from oil-wet to water-wet disperses and mobilizes the solids so that residual organic deposits can be easily removed.

Case history: East Texas

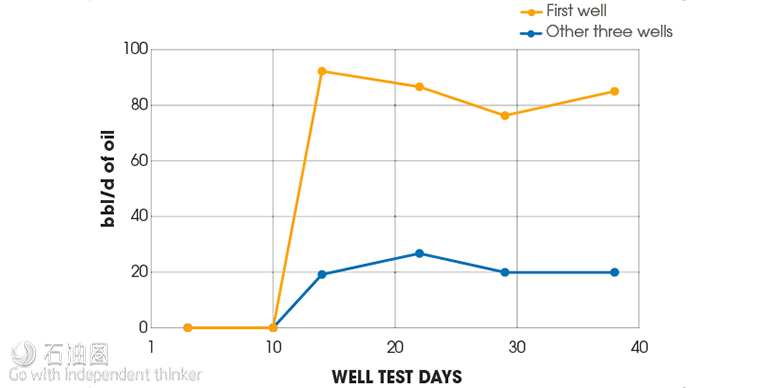

An operator in East Texas, attempting to stimulate production from a mature field, reperforated four wells with a water-based fluid. The wells had known asphaltene and oil-wetting issues. Production was completely lost from all four wells after the workover, and the wells were shut in for several months. Baker Hughes properly diagnosed the root cause of the lost production as multiple damage mechanisms, including wettability alteration. A remediation treatment was performed using the CND500 microemulsion product after a pre-flush pill of Xylene. Xylene as a standalone had been used unsuccessfully in previous treatments without the multifunctional CND treatment.

The wells were treated from 18 in. to 24 in. into the formation. Production from the first well increased 9,000% immediately and stabilized after 5 weeks at a 6,000% increase. The chemical treatment cost was paid for in just a few days (Figure 2). Three additional wells had production increases averaging 2,000% after being treated with the microemulsion product.

石油圈

石油圈