The Lower Tertiary of the Gulf of Mexico (GoM) hosts ultradeepwater oil and gas fields that have long required advanced technologies to maximize their economic returns. One of the most significant challenges in this environment is the sheer depth at which the reservoirs are located—typically below more than 1.6 km (1 mile) of water and in excess of an additional 6,096 m (20,000 ft) of rock. At this depth, extreme downhole pressures during the drilling and completion phases have mandated the development of completely new equipment and products designed specifically for these extreme environments.

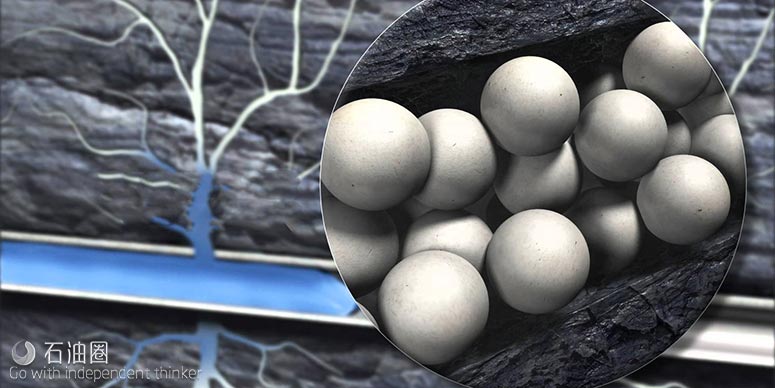

Stress-resistant proppant

After years of research into materials that would perform well in ultradeepwater high-pressure (HP) environments, CARBO developed a proppant at the request of a major oil and gas operator in the deepwater GoM.

KRYPTOSPHERE HD is an ultraconductive high-density ceramic proppant technology designed to withstand the elevated closure pressures at these tremendous depths and extreme cyclic loading conditions for the life of the well. While its manufacturing process still employs typical ceramic steps—pelletizing and sintering—the new process modifies the manner in which the pellets are made. It aims to enable operators to attain higher flow rates at the highest closure stresses and features precision-engineered strong round single-mesh-sized and smooth proppant grains along with an advanced internal microstructure. The sphericity and smoothness of the grains reduces erosive effects and creates a fracture with more space for hydrocarbon flow.

As a result of the improved technology features, significantly higher baseline conductivity at stresses above 10,000 psi compared to typical bauxite-based high-strength proppant were observed, with KRYPTOSPHERE HD maintaining the highest flow rates and levels of conductivity for the productive life of the fracture. The higher flow rates and increased proppant durability increases recovery and return on investment, which lowers finding and development costs per barrel of oil equivalent.

The use of the newly developed proppant technology in the GoM’s Lower Tertiary was in conjunction with a major operator’s first development in this reservoir. Seeking to maximize the productivity of its wells, the operator performed fracture and reservoir modeling to justify the use of this new advanced proppant. To date, IP results have proved better than expected from the wells, and they also have exhibited a higher negative skin than anticipated. As a result, all wells in Phase 1 of development have used or are scheduled to use the new proppant technology.

The operator also desired to minimize the impact of barium sulfate and calcium carbonate scale in its Lower Tertiary completions. When scale formation occurs, it can present itself in the fracture, perforations, downhole screens and inside the wellbore. Standard technology allows inhibition in the wellbore, but remediation and inhibition in the downhole completion, screen, perforations and fracture can be expensive and often difficult to accomplish. To solve this problem, proppant technology was successfully married with SCALEGUARD to address scaling tendencies for the operator.

A unique infusion

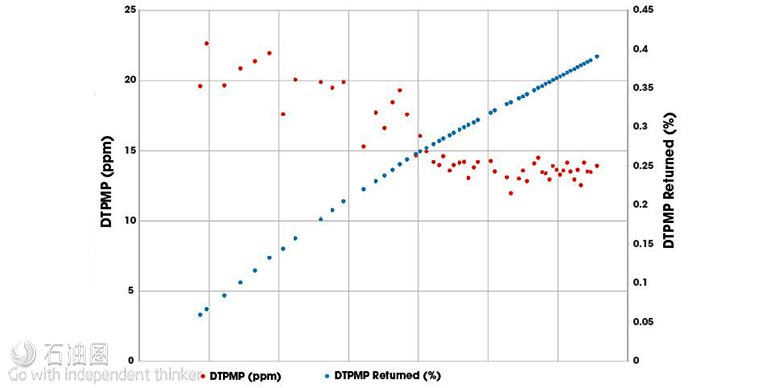

SCALEGUARD technology is a production enhancement technology in which scale inhibiting chemicals are infused directly into ceramic proppant. The technology uses a proprietary process to install interconnected internal porosity in a ceramic proppant grain, infuse that porosity with scale inhibitor and coat the grain with a semipermeable coating. These infused proppant grains are then substituted for a designed amount of the standard proppant and pumped into the fracture during normal fracturing operations. This technology provides a controlled release of the scale inhibitor, resulting in long-term protection against the formation of oilfield scales, and it has provided years of scale inhibition on hundreds of wells.

The technology is designed to safeguard the entire production network—from the fracture through the wellbore to the subsea/surface processing equipment—without compromising fracture conductivity, thereby protecting the operator’s entire asset.

Each treatment can be engineered to last for the effective life of the well based on anticipated production profiles, reducing production maintenance requirements and costs, avoiding workovers and eliminating the potential for production system failures.

The same operator wished to deploy the same technology in its Lower Tertiary GoM wells. Due to the HP environment, SCALEGUARD technology was deployed into KRYPTOSPHERE grains, yielding to the ability to replace up to 20% of the standard KRYPTOSPHERE proppant with SCALEGUARD-based KRYPTOSPHERE without compromising fracture conductivity. This technology also has been deployed in all first-phase wells for this particular operator.

Scale residual results indicate that the scale inhibitor met the operator’s dual objectives of maintaining high conductivity while preventing scale formation and eliminating the need for costly remedial treatments. Furthermore, it is projected that millions of barrels of water will be inhibited in each well.

To simultaneously prevent the formation of scale while maintaining high conductivity in Lower Tertiary GoM completions, the combination of proppant-delivered scale-inhibiting technology and ultraconductive ceramic proppant is recommended. Together, they continue to gain market acceptance as technologies that are proven to deliver higher production wells and reduce the impact of scale, both of which are positively contributing to reduced finding and development costs per barrel for operators throughout the GoM. The success already documented in the completions using these technologies is encouraging the deployment of KRYPTOSPHERE in additional deepwater wells for other operators.

石油圈

石油圈