Pressure Deployment CT System

Optimized equipment for executing long-BHA operations

The pressure deployment CT system facilitates safer, more efficient running of BHA strings that are too long to be lubricated in the wellhead stack. The system combines several equipment innovations to surpass the capabilities of traditional bar deployment, circumventing stack height limitations while running long BHAs.

In contrast with traditional pressure deployment systems that have focused on long perforating strings, this system has the flexibility to deploy other long BHA types as well, including smart-CT applications and the ACTive services portfolio.

APPLICATIONS

(1)CT operations where height restrictions limit BHA length

(2)CT-conveyed perforating

(3)CT logging

(4)ACTive* real-time downhole coiled tubing services

BENEFITS

(1)Improves operational efficiency

(2)Reduces equipment footprint

(3)Increases flexibility for operations

(4)Eliminates many HSE risks associated with conventional bar deployment

FEATURES

(1)Powered sheave with dual-barrier packoff

(2)Hydraconn and work window with quick pressur test functionality

(3)Tool locator

(4)BOP with optimized ram configuration

(5)Ballistic and wired deployment bars

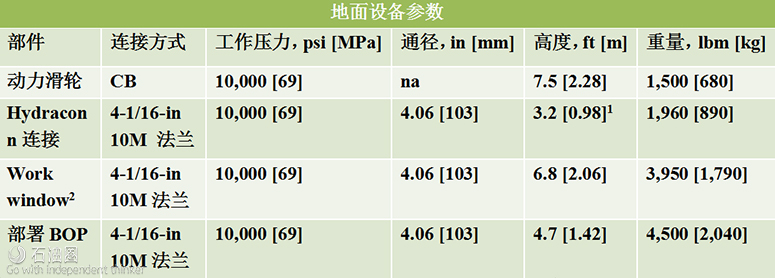

(6)Capability of handling 10,000 psi [69 MPa]

(7)Design rated for H2S service

Minimize equipment footprint and improve location safety

The powered sheave conveys tools and eliminates the requirement for an additional slickline or wireline unit. A redundant wire sealing system provides dual barriers in addition to a blowout check.

The hydraulic quick connection system simplifies and expedites installation and removal of the lubricator and eliminates requirements for personnel to work at heights, improving safety on location.

The large work window simplifies BHA connection and disconnection without exposing operators to work under suspended loads. No-go pins prevent running wire through the BOPs, and a safety valve prevents opening the window under pressure.

Save time and reduce human error

For both the hydraulic connection and the work window, a quick pressure test device eliminates the need to repeat time-consuming shell tests each time a new tool section is added.

An innovative tool locator eliminates human error and cumbersome spaceout calculations by positively locating each deployment joint across the sealing BOP rams. After locating, the rams close to form redundant, testable well barriers. A custom manifold streamlines the testing process and enables pressure testing of each cavity separately.

Ballistic deployment bars serve the dual purpose of transferring the detonation sequence among perforating guns while maintaining a well barrier for deployment and reverse deployment operations. The bars incorporate dual, testable seals on the leak paths.

A dual-purpose skid transports the equipment to location and facilitates temporary injector stacking.

Pressure Deployment CT System Eliminates Two Runs to Reperforate North Slope Well, Alaska

New technology perforates 70 ft in two pay zones in just one run while maintaining dual well control barriers

Background

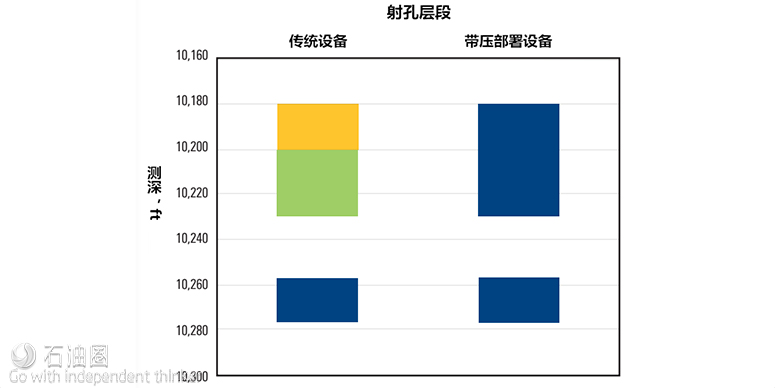

A major operator often perforates North Slope wells with 30-ft [9.1-m] BHAs run on coiled tubing. The BHA length is limited by height restrictions of the CT mast units, which are preferred because of their efficiency compared with conventional CT units.

However, each well can have as much as 150 ft [45.7 m] of pay to be perforated. This consistently necessitates additional CT runs, increasing the amount of time on location and fluids pumped in the job.

Solution

Pressure deployment CT system

In its first operation, the pressure deployment CT system was used to perforate segments totaling 70 ft [21.3 m] in just one run with 35 bbl [5.6 m3] of fluid compared with three runs and 100 bbl [15.9 m3] of fluid for a conventional operation limited to 30-ft BHAs. The use of time-delay fuses enabled perforating two separate zones without blank guns.

石油圈

石油圈