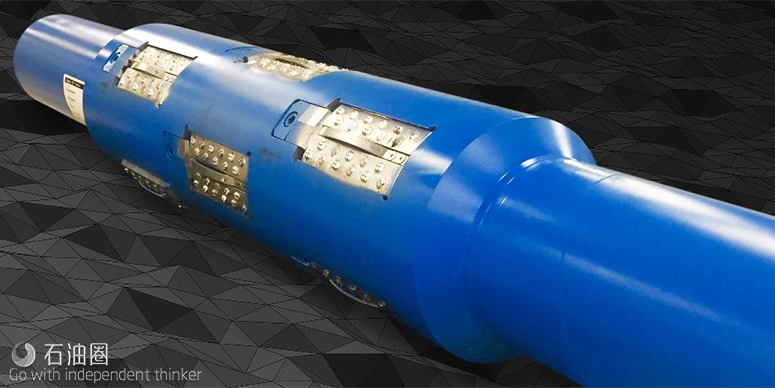

MASTODON Hydraulic Pulling Tool

The Baker Hughes MASTODON™ hydraulic pulling tool pulls objects from cased wellbore using hydraulic pump pressure. It anchors in the casing, exerts a pulling force on the fish below, and transmits the force to the casing rather than the surface equipment. This design allows the pulling tool to be used with most conventional workover rigs and small workstrings. It can be used to pull liners, retrievable packers, or any other objects that require heavy pulling strains. It also can be used with mechanical fishing tools such as an overshot, spear, or screw-in assembly.

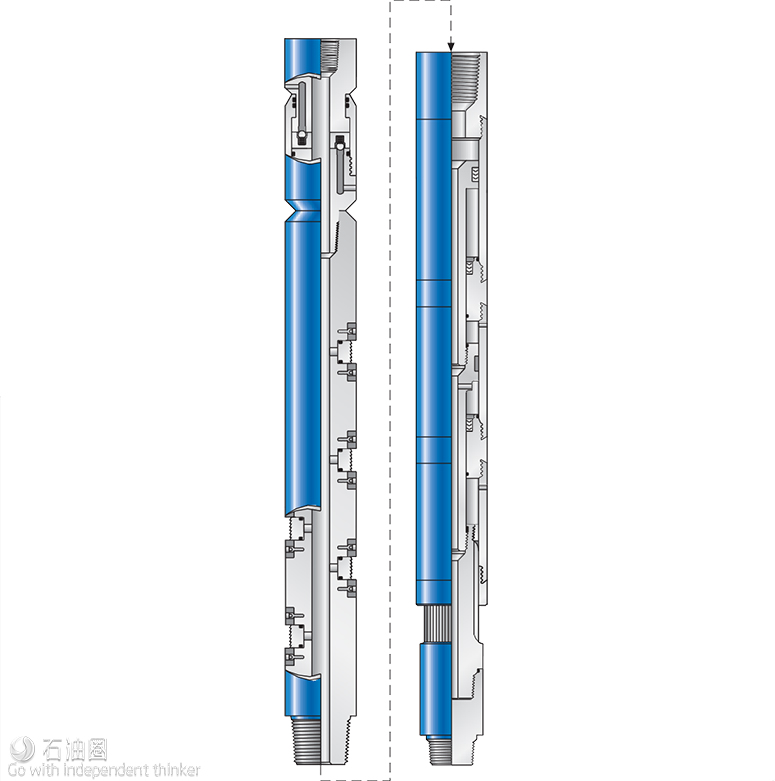

The MASTODON tool is composed of three sections:

(1)The anchor section provides a large slip engagement area, anchoring the tool to the casing wall to safely transmit the heavy pulling strains with minimum risk to the casing.

(2)The power section actuates with hydraulic force to apply a pulling force to the fish. The power section exerts its tremendous pulling force throughout a 24-in. stroke up to a1.8 MM pound force.

(3)The relief valve provides a means to bleed off the well fluid, as the pipe is pulled out of the hole. For smaller size tools, the valve is run on top of the tool and allows for release of the slips if differential pressure exists. For the largest tools, the relief valve is run at the bottom and provides a means to pressure up and activate the tool, opening after pressure is released without dropping any balls or darts from surface.

Applications

(1)Pulls objects from cased wellbore

(2)Pull anything requiring heavy pulling strains

(3)Use with:

–Conventional or low-weight capacity workover rigs

–Small workstrings

–Hydraulic pump capable of 10,000 psi

Features and benefits

(1)Multiple offset anchors design

–Better grip to the casing

–May be run with low weight capacity workover rig

–The anchor pistons are hydraulically actuated by the same pressure that applies the pull

(2)Robust design

–May be run in high temperature environment

(3)API regular connection

–May be run with any mechanical fishing tool

(4)Applies tremendous pulling force

–Provides twenty-four inch stroke

–Able to apply as many consecutive pulls as necessary to free the fish

CASE HISTORY

MASTODON Hydraulic Pulling Tool Successfully Removed Stuck Casing, Saved Operator More Than USD 1.5 MM

Background and Challenges

■Well abandonment operation

■Retrieval of 9 5/8-in. casing that had settled barite and cement behind casing

Baker Hughes Solution

■Delivered a robust and reliable solution using the MASTODON hydraulic pulling tool to pull heavy objects from the wellbore

■Confirmed ability to handle multiple pressure cycles and jar impacts without damaging the tool or stuck object

Results

■Successfully retrieved 300 ft of stuck casing

■Avoided 300 ft of casing milling and need for swarf handling system

■Eliminated multiple trips downhole compared to conventional cut and pull operation

■Saved the operator more than USD 1.5 million with efficient solution

An operator working in the Norwegian Continental Shelf was performing a well abandonment operation and needed to remove 9 5/8-in. casing that was stuck in the wellbore due to the presence of barite and cement. The operator wanted to avoid the excess time and costs associated with conventional cut and pull operations—which typically requires multiple trips to retrieve casing down to desired depth—so they reached out to Baker Hughes for a solution.

Baker Hughes recommended the MASTODON™ hydraulic pulling tool, which is capable of pulling stuck casing from a cased wellbore using hydraulic pump pressure. The tool anchors in the casing, exerts a pulling force on the fish below, and transmits force to the casing rather than the surface equipment. This approach helps reduce the number of trips downhole, saving the operator time and money.

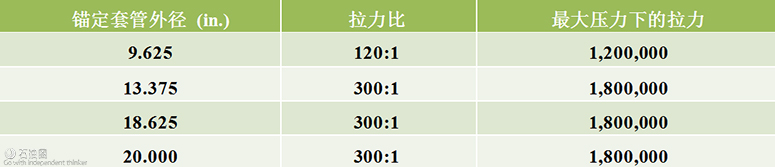

The 13 3/8-in. MASTODON hydraulic pulling tool provides 24 in. stroke up to a 1.8 million lb force, only limited by the yield strength of the 9 5/8-in. casing or the compression strength of the 13 3/8-in. casing. The tool provides 300:1 pressure versus pull ratio with a pressure capability of 6,000 psi (414 bar).

During the first pressure cycle, 3,000 psi (207 bar) was applied on the tool which provided a pulling force of 900,000 lbs. After 36 pressure cycles, the casing pulled free, resulting in successful retrieval of 300 ft (91 m) of the 9 5/8-in. casing. This not only saved the operator three days of milling time, but also prevented the need for a swarf handling system and additional wellbore clean out trips, resulting in over USD 1.5 million in savings.

The operator opted to perform a second run to retrieve an additional 300 ft where 71 pressure cycles were applied on the tool along with 58 jar impacts and an overpull of 240,000 lbs. But, in efforts not to exceed 80% yield strength of the 9 5/8-in. casing, it was decided to release and pull out of the hole.

Despite application of 107 pressure cycles and 58 jar impacts, the tool showed no signs of leakage or failure when inspected on surface. Using the MASTODON tool, Baker Hughes delivered a robust and reliable solution for consecutive heavy pulling and multiple jarring operations to pull stuck casing from the wellbore.

石油圈

石油圈