Thermal steam stimulation (TSS) is considered the most effective of current methods for heavy-oil production. However, the method has problems with low coverage by steam injection and decreased efficiency at later stages of development. This paper presents the results of solving these problems by combining thermal steam and physicochemical stimulations and using “cold” technologies involving thermotropic gel-forming and oil-displacing systems.

Introduction

In Russia, the amount of oil reserves considered difficult to recover is constantly increasing. Active reserves account for one-third of all prospected reserves, and the difficult-to-recover oil reserves account for 67%. High-viscosity oils are 13% of the difficult-to-recover oils, and low-permeability formations account for 36%. The amount of heavy and high-viscosity oil is several times greater than the amount of light and low-viscosity oil. Therefore, the development of the deposits of heavy and high-viscosity oils is given more attention. To develop heavy- and high-viscosity-oil reservoirs effectively and increase oil production, new, integrated enhanced-oil-recovery (EOR) technologies are necessary. The new technologies addressed here combine basic reservoir stimulation by water or steam injection and physicochemical methods, increasing reservoir coverage and oil-displacement factors and improving the development.

In recent years, thermal methods—oil displacement with steam, cyclic steam injection, and steam-assisted gravity drainage—have been the most widespread EOR methods used in heavy-oil fields. One can improve the efficiency of steam stimulation by combining it with physicochemical methods—in particular, using thermotropic gel-forming and oil-displacing systems—thereby increasing the reservoir coverage by steam injection and providing additional oil displacement.

Integrating Physicochemical Methods and TSS

This approach uses the concept that reservoir energy or energy from an injected heat carrier can generate in-situ “intelligent” chemical systems (i.e., gels, sols, surfactant solutions, and buffer systems with controlled alkalinity). These systems remain for a long time and are self-supporting in reservoirs with complex properties, making them optimal for oil displacement.

To increase oil recovery from heavy- and high-viscosity-oil reservoirs at later stages of development and to improve the efficiency of thermal-steam and cyclic-steam stimulations, an EOR technology has been created that alternates thermal-steam and physicochemical stimulations by surfactant-based systems, which generate carbon dioxide (CO2) and alkaline buffer solutions in situ. The application of the technology at a stationary steam-injection site in the Usinsk oil field in Russia decreased water cut by 10–20% and increased oil-flow rate by 40%. At a cyclic-steam-stimulation site in the Liaohe oil field in China, oil production increased 1.8–2.3 times, the period of oil production was prolonged 3–5 months, and oil viscosity decreased by three times.

The dominant technique in these new stimulations is the use of gel technologies to increase reservoir coverage by waterflooding. Under surface conditions, thermotropic gel-forming systems are low-viscosity aqueous solutions. Under reservoir conditions, they are converted into nanostructured gels. Gelation occurs because of thermal energy from the heat carrier, without any crosslinking agents.

Field tests of the integrated technologies, combining thermal-steam and physicochemical stimulations, were conducted in high-viscosity-oil fields in Russia and China. The increase in oil-flow rate ranged from 3 to 24 tons/D per well. Incremental oil production was 980 tons per well treatment. Geophysical studies conducted before and after injection of the gel-forming system showed a redistribution of filtration flow and increased reservoir coverage by TSS. After the injection of the systems into 41 steam-injection wells in the Usinsk oil field, the oil-flow rate increased by 4–30 tons/D and water cut decreased by 5–20%.

Gelled Oil-Displacing System Using Surfactants With Controlled Viscosity

To improve the areal injection of heat carriers (steam or hot water) and cyclic steam stimulations of production wells, a gelled oil-displacing system using surfactants with controlled viscosity has been created. This system is an extension of the concept of using reservoir energy or that of the injected heat carrier to generate in-situ “intelligent” chemical systems. Compositions based on surfactants and alkaline buffer solutions last for a long time and are self-supporting, which are optimal properties for oil displacement.

The systems use ammonium salt and carbamide, which generate CO2 and ammonium buffer solutions in situ, providing the colloidal chemical properties of the surfactants, optimal for oil displacement and preserved in a wide range of concentrations, reservoir water salinities, and temperatures. This results in reduced oil viscosity, interfacial tension, and clay swelling as well as increased mobility of reservoir fluids, thereby increasing the oil-displacement factor.

Because of the introduction of gelling agents to the system, which provides a controlled increase in viscosity, the surfactant-based system becomes both flow-deflecting and oil-displacing and can be used to improve the efficiency of the TSS because of increased sweep efficiency and oil-displacement factors.

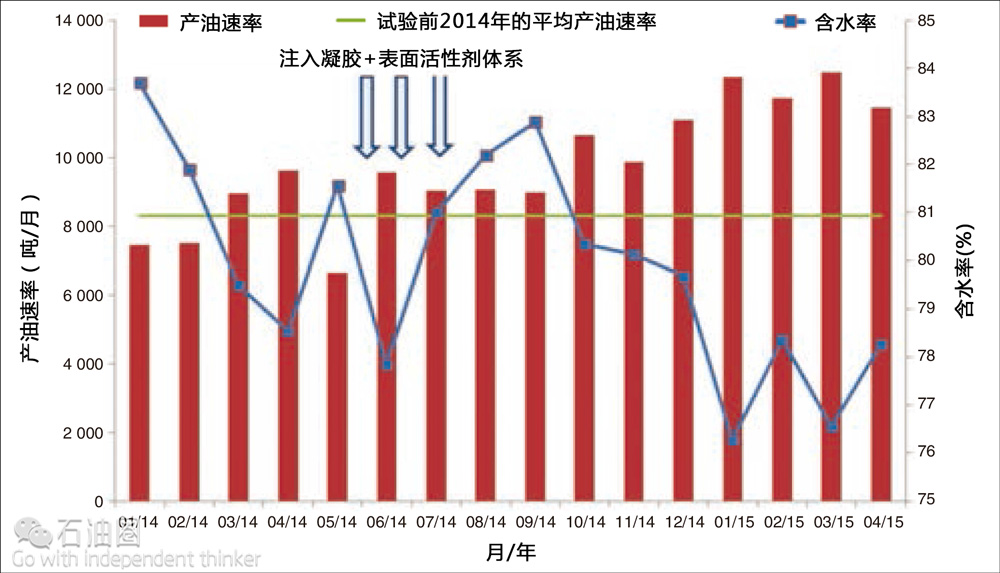

From 15 June to 31 July 2014, the gelled surfactant-based system was injected into five steam-injection wells in the Usinsk oil field. The volume injected ranged from 80 to 110 m3. Standard oilfield equipment was used to prepare and inject the gelled system under field conditions. The effect was monitored, and a positive effect was clearly defined 3 months after the injection (Fig. 1).

EOR From Heavy-Oil Reservoirs Without Thermal Stimulation

To enhance oil recovery from high-viscosity-oil reservoirs without TSS at temperatures between 20 and 40°C, the authors proposed using gels and sols based on a low-temperature gel-forming system as well as alkaline and acid oil-displacing systems based on surfactants, an inorganic buffer solution, and polyol with controlled viscosity. These are compatible with high-salinity formation water and have low freezing points (between −20 and −60°C).

To enhance oil recovery from high-viscosity-oil reservoirs without the TSS, the authors proposed the “cold” technology of cyclic reagent stimulation, which is similar to cyclic steam stimulation. A slug is injected into the production well and followed by water injection, and the well is closed for 7–14 days before being put into operation. The oil is produced as a low-viscosity emulsion. After the first cycle of oil production, the next cycle is performed: injection of slug and then water followed by well shutdown and then oil production.

Conclusion

All the technologies presented in this paper have had their efficiencies proved under field conditions and are recommended for further pilot projects and commercial applications. One should note the high processability of these systems because they can be prepared and injected by standard oilfield equipment.

Flow-deflecting technologies based on the use of the gel-forming and sol-forming systems for injection wells are recommended for oil fields or areas large enough to have significant effect.

“Cold” technologies intended to enhance oil recovery and intensify oil production from low-productivity wells are considered promising technologies because of good results from the pilot tests as well as the potential flexibility and selectivity of their application in the most appropriate wells. Moreover, these technologies are suitable for cyclic application (cyclic reagent stimulation, analogous to cyclic steam stimulation but without heating the injected fluid).

Large-scale commercial application of these new integrated technologies—combining water or steam injection with physicochemical methods that increase the reservoir coverage—will extend the profitable exploitation of oil fields in later stages of their development and boost production at oil fields with difficult-to-recover hydrocarbon reserves, including heavy- and high-viscosity-oil reservoirs and deposits in the Arctic.

石油圈

石油圈