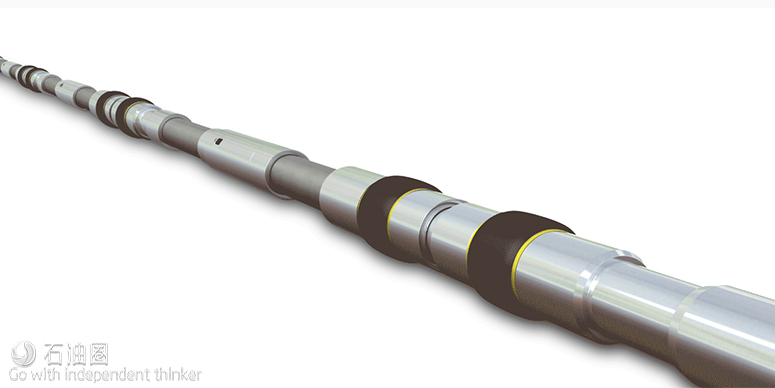

Titanium XV System

High Pressure/High Temperature Multi-stage Completions

Packers Plus StackFRAC® Titanium® XV systems are designed for open and cased hole, multi-stage stimulation in wells where differential pressures exceed 10,000 psi (69 MPa) and extreme bottom hole temperatures can be encountered.

The Titanium XV system was developed with the same function and design as the Packers Plus StackFRAC HD system, which uses a continuous pumping operation to effectively stimulate isolated zones along the entire length of the wellbore. This enables the field-proven StackFRAC Titanium XV system to greatly simplify multistage fracturing operations, reducing completion time and cost. After stimulation, the well can be immediately flowed back and put on production.

Because the Packers Plus StackFRAC Titanium XV system is modular with regard to tool placement, it can be combined with other Packers Plus tools and systems, enabling customized design for targeted delivery of the stimulation program.

The StackFRAC Titanium XV multi-stage completion system offers many features and benefits:

–Mechanical stage isolation with field-proven Titanium XV RockSEAL® packers

–Continuous rigless pumping operation reduces completion time and cost

–Access to natural fractures in open hole applications

–Custom stimulation of the entire wellbore

–Immediate flowback after stimulation

–Improved production results

–Compatible with other Packers Plus systems and tools

Mitigates risk associated with burst and collapse scenarios:

– 15,000 psi (103 MPa) burst and collapse on all metal parts

– Integration of premium threads and seal technology

– High torque shouldered connections

The StackFRAC Titanium XV high pressure/high temperature mulit-stage completion system can be used in many applications:

–Open and cased hole horizontal and vertical wells

–Multi-stage stimulation

–Tight oil and gas formations

–High treating pressure in zones with high fracture gradients/breakdown pressures

See what the StackFRAC Titanium XV system is made of:

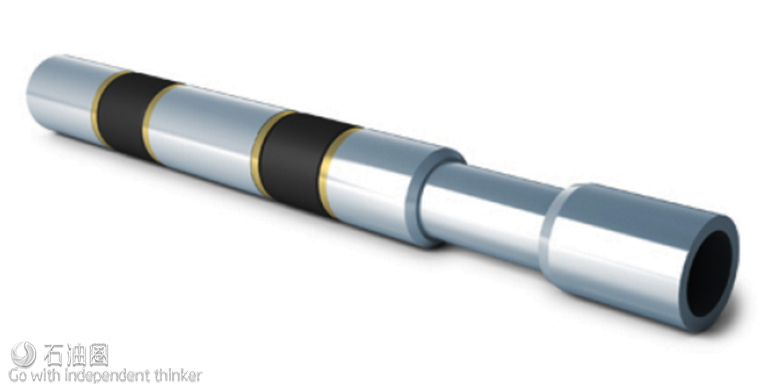

Titanium XV RockSEAL Packer

The Titanium XV RockSEAL packer is a dual-element, hydraulically set open hole packer that combines the sealing strength of a mechanical element with the setting force of a dual-piston cylinder and mechanical body-lock system. This packer has a specially designed elastomer with the largest possible cross section to provide excellent expansion ratios to set in oversized holes. The Titanium XV RockSEAL packer is also designed with anti-preset features that allow it to be pushed through tight spots in the well without pre-setting or shearing the packer.

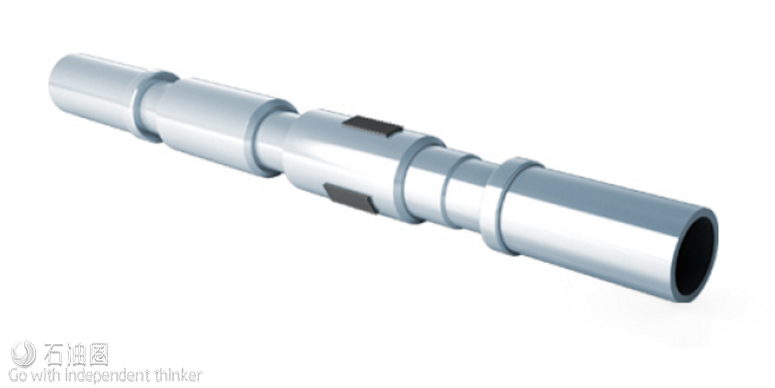

Titanium XV Hydraulic Anchor

The Titanium XV Hydraulic Anchor is a hydraulically set anchor used in HPHT stimulation systems. This anchor secures the system in the wellbore to prevent movement, which can cause tool damage. The tool features a slip arrangement with exceptional holding power to keep it from moving under the hydraulic and mechanical forces that may be exerted on the tool. It can provide extra anchoring for stimulation at the toe of the wellbore or anywhere along the system that requires extra stability.

Titanium XV Drillable Closeable FracPORT Sleeve

The Titanium XV Drillable Closeable (DC) FracPORT™ sleeve is a ball actuated, hydraulically activated injection/production port used in Titanium XV stimulation systems. The Titanium XV DC FracPORT sleeve is run between two Titanium XV RockSEAL packers to allow specific zones of the wellbore to be isolated and selectively stimulated. This sleeve can be closed or reopened for future operations. This allows for effective water or gas shutoff, flow control, re-fracturing and production testing. A standard Titanium XV FracPORT sleeve is also available.

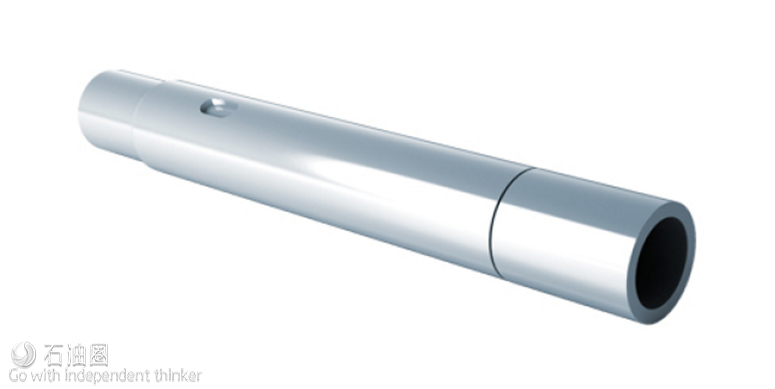

Titanium XV Hydraulic FracPORT Sleeve

The Titanium XV Hydraulic FracPORT sleeve is a hydraulically activated injection/production port used in the first stage of Titanium XV stimulation system applications. This sleeve opens at a specific pressure allowing for communication between the tool string and the annulus. The unique configuration of the Titanium XV Hydraulic FracPORT sleeve ensures full opening for effective stimulation of the first stage. It is also available in a closeable version that can be re-opened for future operations.

Case study of Titanium XV System

Background

The Duvernay is the latest emerging liquids-rich shale play in Alberta and covers a surface area of approximately 100,000 km². Best known as the source rock for the Devonian-aged Leduc Reef, Keg River and Slave Point formations, development in the Duvernay is currently in its infancy. It has drawn many comparisons to the Eagle Ford Shale in the United States due to its high liquids content.

The formation is composed of interbedded bituminous shales, calcareous shales and dense argillaceous limestones. The thickness of the formation varies, ranging from 10 m to 70 m depending on the location. Approximate depths range from 2,500 m to 4,000 m. Formation characteristics of the Duvernay are very limited; however, estimates in the Kaybob region have indicated a porosity range of 3 to 12% and permeability up to 0.01 mD. Sweet spots in the formation are yet to be determined, but will be exposed as more wells are drilled in the area. The Duvernay was once thought to be uneconomical to produce and, consequently, was largely ignored until the advent of horizontal drilling and multi-stage fracturing began unlocking resource plays.

Challenge

As operators continue to drill and complete deeper and increasingly challenging wells in emerging plays, they are relying on advances in completion technology, which can accommodate high pressure and high temperature (HPHT) ratings to perform the desired stimulation. Formations with high fracture gradients result in higher breakdown pressures, and thus the need to achieve higher treating pressures in order to effectively stimulate wells. Formation heterogeneity along the lateral can also lead to greater than expected differential pressures where each isolated zone has a different breakdown pressure to initiate a fracture. Downhole tools with higher pressure capabilities mitigate the risk of burst and collapse scenarios often encountered in zones where these conditions exist.

Solution

The Packers Plus StackFRAC® Titanium® XV system addresses the need for completion systems in wells where differential pressures above 69 MPa (10,000 psi) could be encountered. Titanium XV HPHT tools are capable of withstanding differential pressures of 103 MPa (15,000 psi) and extreme bottom hole temperatures. This was achieved through the use of an innovative metallurgical composition and premium seal technology. Higher pressure capabilities also allow operators to increase pumping rates, lateral lengths and the number of stages to be fractured.

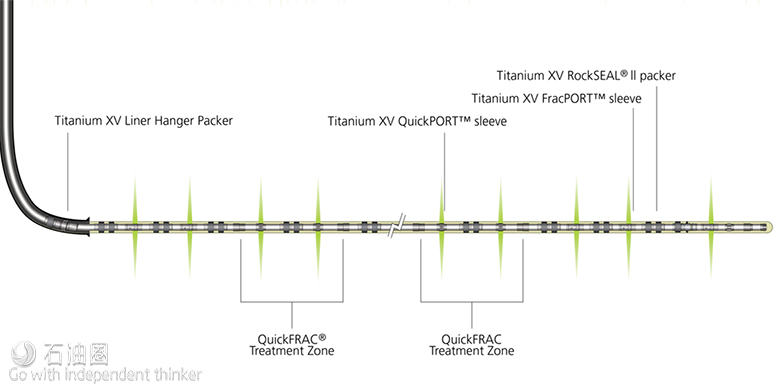

The Titanium XV system was developed with the same function and design as the Packers Plus StackFRAC system, which uses a continuous pumping operation to effectively stimulate isolated zones along the entire length of the wellbore. Mechanical isolation is achieved with the Titanium XV RockSEAL® ll packer. A Titanium XV FracPORT™ sleeve is run in between two packers to allow specific zones of the wellbore to be selectively fractured.

In addition, HPHT tools have also been developed for the QuickFRAC® batch fracturing system to allow for limited entry stimulation in open hole completions. All Packers Plus systems are modular, allowing combination StackFRAC and QuickFRAC Titanium XV HPHT systems to be run together. This method maximizes the number of stages available while maintaining the largest ball seat size possible for coiled tubing intervention.

Results

An operator targeting the Duvernay shale in the Kaybob region completed a 25-stage well with a combination StackFRAC and QuickFRAC Titanium XV HPHT system. The system was run into a wellbore with a lateral length of 1,735 m, true vertical depth of 3,392 m and measured depth of 5,160 m. Bottom hole pressure in the wellbore was 47 MPa and bottom hole temperature was 115°C.

During the slickwater fracture treatment, the surface treating pressure and pump rate reached 69 MPa and 16.5 m³/min, respectively. Pump rates ranged from 8.2 m³/min to 16 m³/min during stimulation operations. An average of 98 tonnes of proppant and 1,000 m³ of slickwater were used per stage to fracture the well for a total of 2,440 tonnes of proppant and 25,030 m³ of slickwater.

The Titanium XV system allows the installation and stimulation of challenging wells in areas that could previously not be completed. StackFRAC Titanium XV systems have been run in shale and tight sandstone reservoirs in Canada including the Montney and Duvernay. Packers Plus is the innovator of open hole multi-stage fracture stimulation systems and is an industry leader in designing and manufacturing technology-based solutions for a variety of completion challenges.

石油圈

石油圈