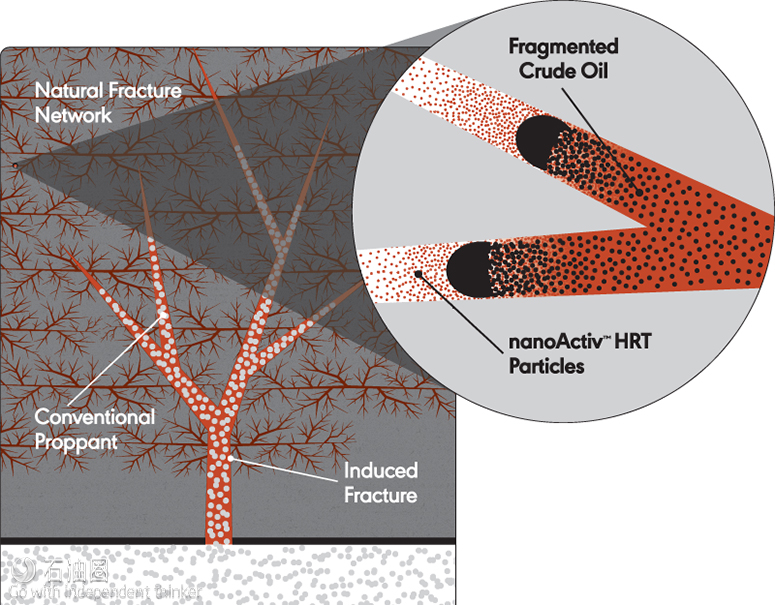

Improving the ability of well intervention technologies, such as hydraulic fracturing and remediation, to effectively and efficiently stimulate productivity remains a challenge. Steep production declines after high initial production and less-than-optimal fracturing results indicate that significant proppant quantities are not reaching the available induced or natural fracture network. Nissan Chemical America Corporation (NCA) introduced nanoActiv HRT, a high-efficiency hydrocarbon recovery technology well-intervention additive package, to address this challenge. NCA’s nanoActiv HRT particles penetrate beyond the induced fracture network on a nanoscopic scale, rapidly and extensively saturating a significant portion of the natural fracture network. Producing a diffusion-driven mechanical process known as “disjoining pressure,” nanoActiv HRT particles deliver long efficacy in the recovery of hydrocarbons, fragmenting them into smaller droplets and enabling an efficient backflow to the wellbore. Over the past 2 years, this new technology has been applied in more than 45 Permian Basin wells in several reservoirs (Wolfberry, Wolfcamp B, Wolfcamp Sand, Brushy Canyon, Woodford, and San Andres) and also in North Dakota (Three Forks, Bakken, and Codell-Niobrara). In these applications, nanoActiv HRT has significantly reduced decline rates after stimulation while consistently delivering higher oil cuts and gas/oil ratios in conventional and unconventional reservoirs.

The Problem

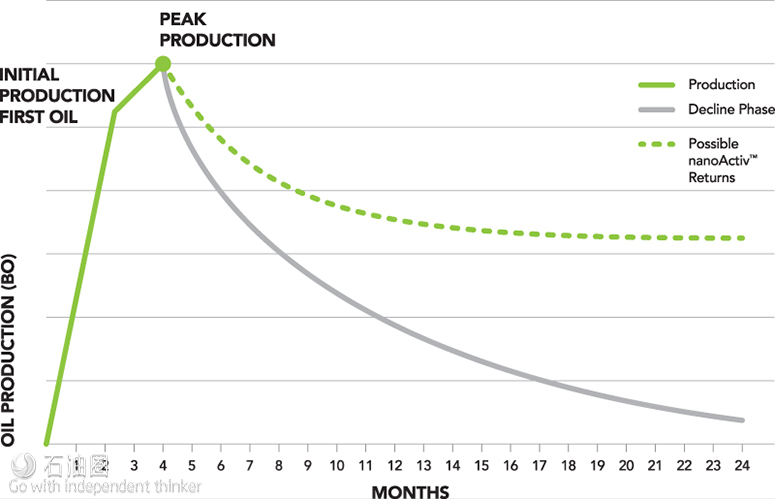

The Production Challenge: Steep production decline curves mean there is intense pressure to keep replacing the production lost year over year.

Operators are looking for ways to get more oil out of existing wells without expensive refracturing or other intervention technologies.

The Solution

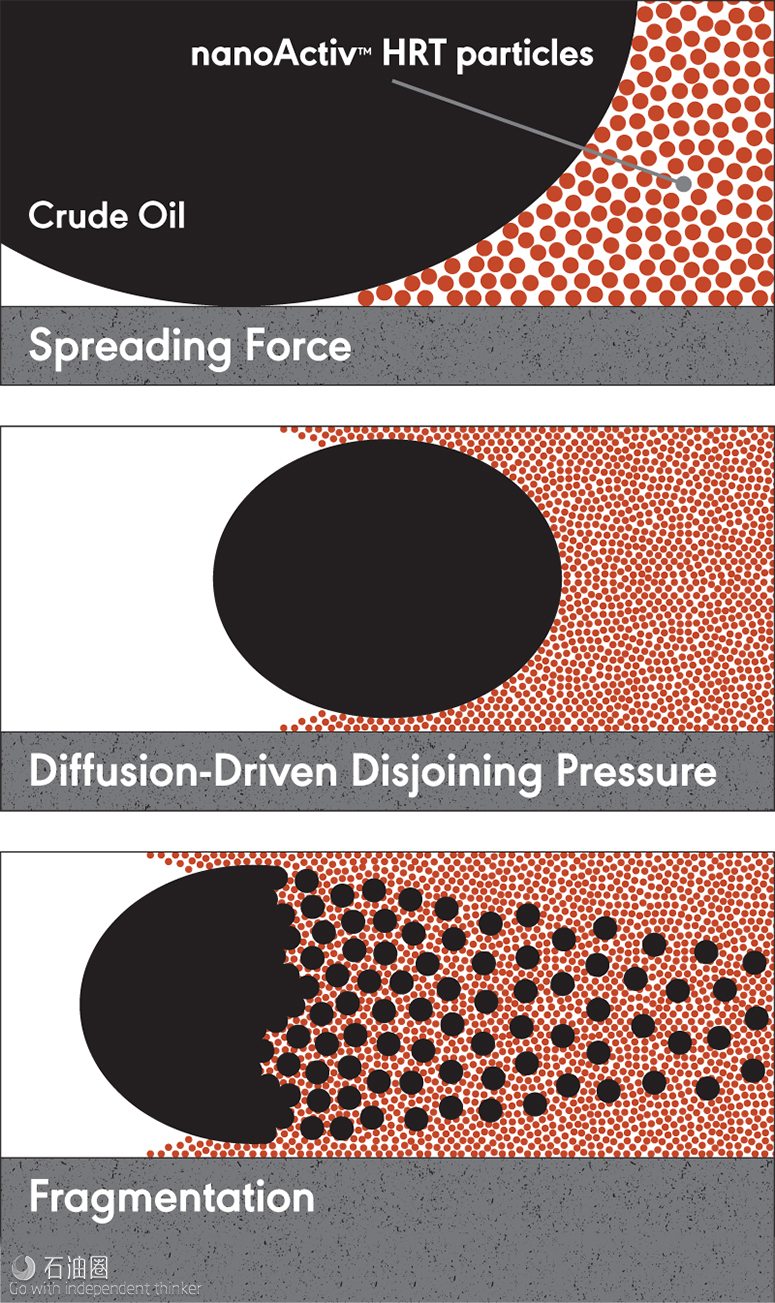

nanoActiv® HRT utilizes nano-sized particles in a colloidal dispersion. These particles produce a Brownian-motion, diffusion-driven mechanism known as disjoining pressure to produce long efficacy in the recovery of hydrocarbons in conventional and unconventional reservoirs.

nanoActiv® HRT moves throughout the fracture network releasing hydrocarbons as it goes deeper and farther than any product on the market today.

How does it work?

nanoActiv® HRT Wedge Effect Mechanism: Diffusion-Driven Disjoining Pressure

nanoActiv® HRT solutions behave as a wedge film driven by Brownian motion and diffusion defined as disjoining pressure—greatly facilitating and accelerating the mobility of gas, oil and water, or mixtures thereof within porous media, and/or natural or induced fracture networks.

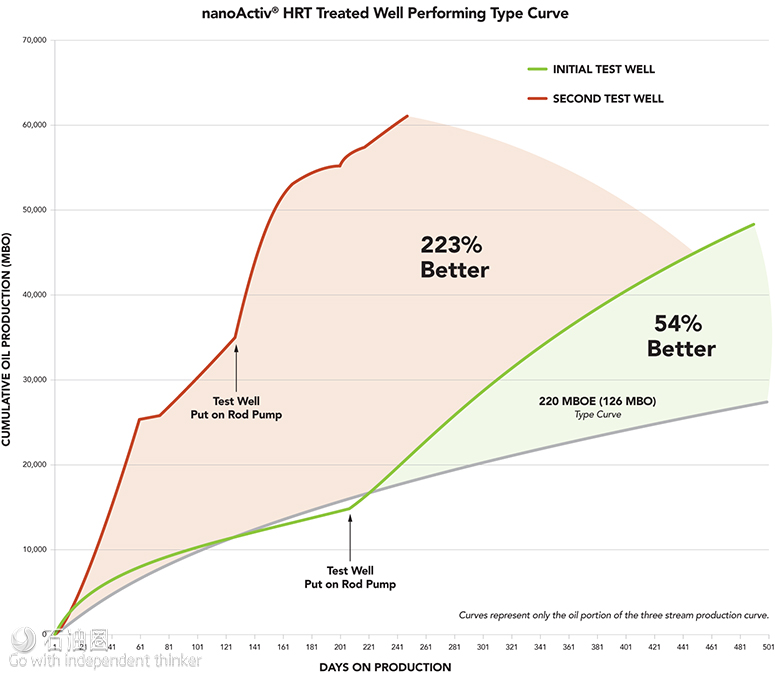

Numerous factors affect the performance of an oil well—the geology, the number and size of treatment stages, the choice of additives, etc. nanoActiv® HRT treated wells have shown meaningful performance improvement versus comparative wells from the same operators. While no single technology or treatment can account for the entire performance of an oil well, the effects of nanoActiv® HRT are significant and compelling.

A History of Success

Nissan Chemical America Corporation is a division of Nissan Chemical Industries (NCI), founded in 1887 as the first chemical fertilizer manufacturer in Japan. A forerunner in chemical innovations for nearly 130 years, Nissan Chemical currently manufactures products for the chemical, agrochemical, and pharmaceutical industries and is a market leader in the production of nanoparticles for the automotive, coatings, electronics, and oil and gas industries.

石油圈

石油圈