After significant R&D focus, Tendeka has recently launched PulseEight, the latest advance in wireless intelligent completion technology for the digital oilfield.

Tendeka’s PulseEight system uses unique pressure pulse telemetry to channel wireless communication between a well’s downhole monitoring and control system and the wellhead. Previously, Tendeka installed several Wireless Pressure / Temperature gauges and so proved communication from the wellbore to the wellhead. This relayed critical reservoir pressure and temperature data which the client used for depletion monitoring and for the planning of an infill drilling campaign.

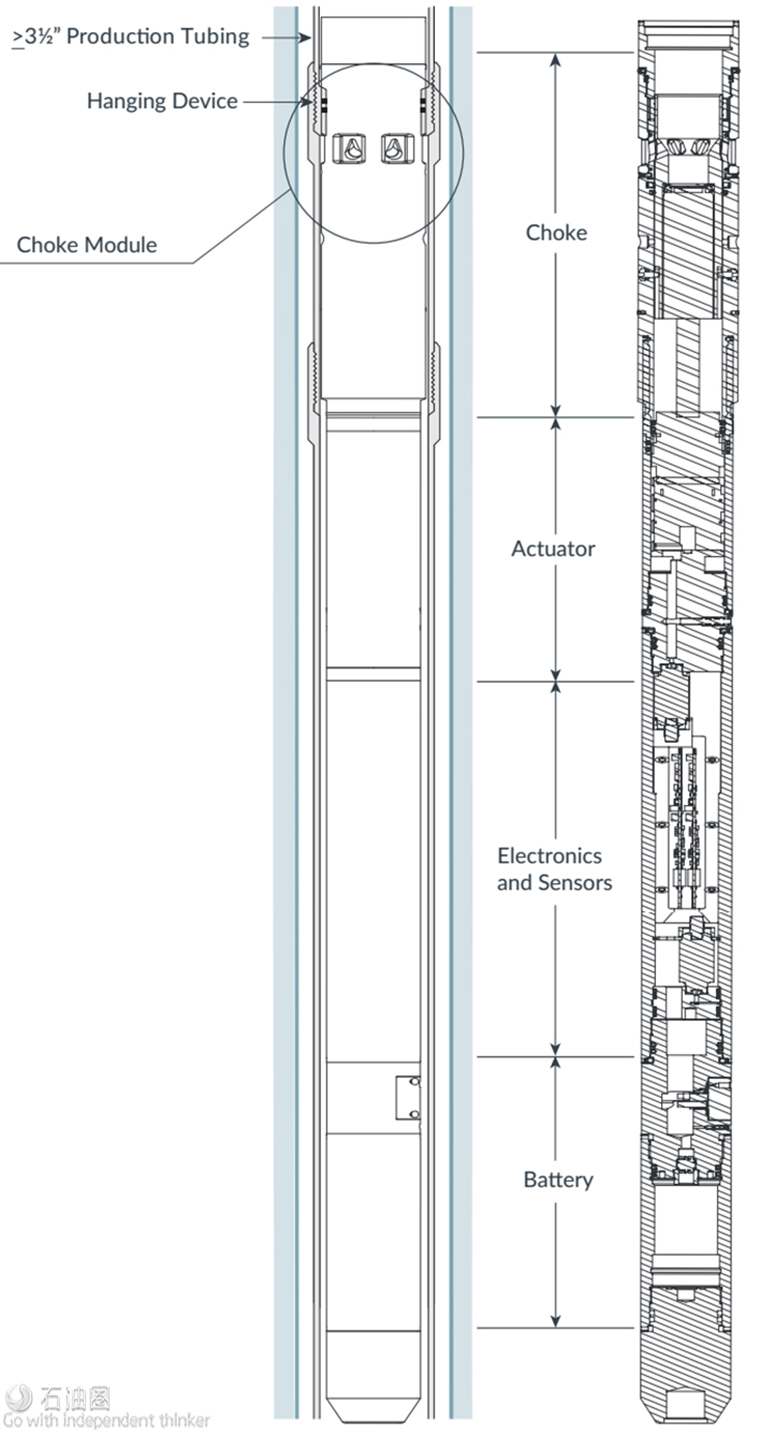

To unlock the full potential of the system and allow for greater control, Tendeka embarked on a project to prove bi-directional communication via a PulseEight Interval Control Valve (ICV). The device was required to send Pressure / Temperature data to the surface and pressure pulses were sent down the well to communicate with the ICV in a multi-phase fluid environment.

PulseEight technology simplifies operations by removing the need for traditional hydraulic or electric control lines. Downhole connections are eliminated and therefore overall system costs are significantly reduced and HSE is improved. The device can either be fitted during the completion phase, or retrofitted into existing wells in order to maximise production.

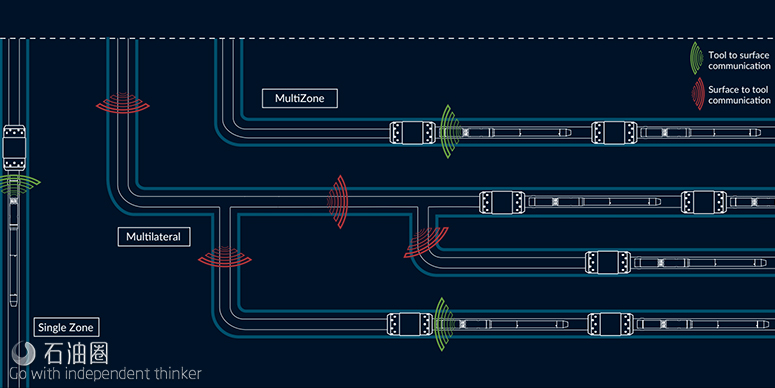

Each device functions independently providing modular flexibility to meet a range of requirements from low cost single zone monitoring to full multi-zone, multi-lateral measurement and control. With PulseEight there are no limits to what can be achieved.

PulseEight wireless intelligent completion technology provides operators with more options to extend the life of their existing assets, and to develop new fields more effectively. PulseEight uses a unique pressure pulse telemetry suitable for multi-phase fluid environments that allows wireless communication between downhole and the wellhead.

Features

– Unique pressure pulse telemetry removes the need for downhole cables

– No signal boosters required as no depth limitations

– Interfaces with existing surface infrastructure – no additional surface kit required

– Infinitely variable choke for optimal production

Benefits

– Simplifies completion operations reducing rig time

– Reduces system costs by eliminating control lines

– Improves barrier integrity through removal of feed-through connections, minimising downtime

– Enables intelligent completion solutions in existing wells, without a workover

– Provides interval control without intervention

– Improved HSE

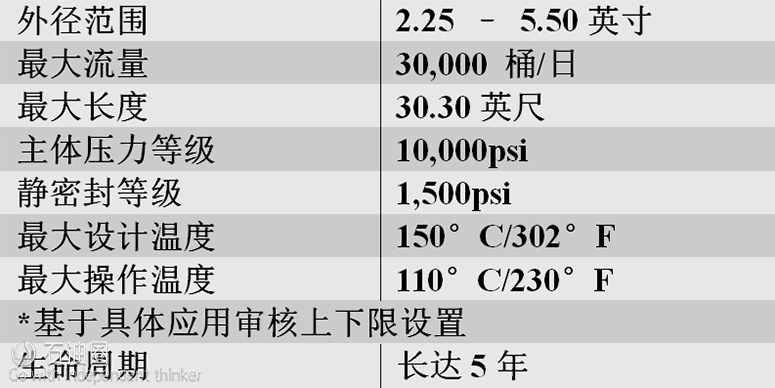

Technical Specifications

OD Range 2.25” – 5.50”

Max Rate 30,000BPD

Max Length 30.30ft

Body Pressure Rating 10,000psi

Static Seal Rating 5,000psi

Unloading Seal Rating 1,500psi

Max Design Temperature 150°C/302°F

Max Operating Temperature* 110°C/230°F

*Qualified limit, can review on application basis

Lifetime Up to 5 years

Applications

– Pressure / Temperature Monitoring

– Interval Control

– Multi-lateral Well Control

– Water and Gas Shut-off / Control

– Remote Barrier for multi-stage frac applications

– Autonomous Gas-lift optimisation

– Gas Hydrate Prevention

– Cross-flow Prevention

Case Study 1:

PulseEightTM wireless intelligent completion technology regains P/T data from clients wells in Norway

The PulseEight product range from Tendeka uses unique‘pressure pulse telemetry’to regain pressure & temperature from clients wells.

A Scandinavian operator had experienced downhole pressure and temperature gauge failure in their well, losing vital data required to plan for tertiary recover techniques in this mature and heavily depleted field.

Tendeka Solution

Tendeka restored measurements using the PulseEight Wireless PT Gauge. No surface acquisition equipment or data relay system was required as the existing wellhead pressure sensor was used to read the signal.

Project Results

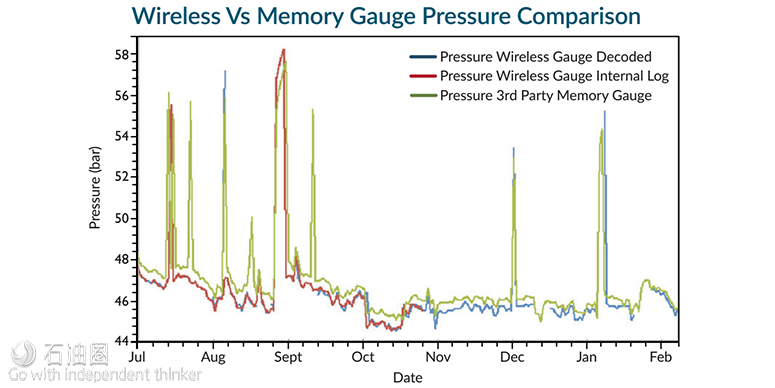

The gauge transmitted data for 226 days, on retrieval the data was compared to a memory gauge deployed in the assembly confirming the veracity of the transmitted and recorded Wireless Gauge data.

–Successful installation, hanging off the WDG on an IDSP Packer

–Successful downhole data acquisition.

–Successful wireless transmission to surface.

Case Study 2:

PulseEightTM wireless intelligent completion technology delivers P/T data from clients wells in Norway

The PulseEight product range from Tendeka uses unique‘pressure pulse telemetry’to deliver pressure & temperature data to surface, without control line.

Norway’s largest gas reservoir has been on-line since 1996 and is expected to continue production for the next 70 years. Declining pressure means that more compression is required to drive production and an accurate understanding of reservoir pressure and decline is critical to meeting contractual gas deliveries and achieving recovery targets.

– Obtain bottom hole data to aid production optimisation

– Use an intervention based solution to enable data collection beyond the service life of permanent gauges

Tendeka Solution

Tendeka installed the PulseEight Wireless PT Gauge to provide daily flowing bottom hole pressure and static well data following a shut-in. No surface acquisition equipment or data relay system was required as the existing wellhead sensors are used to read the signal.

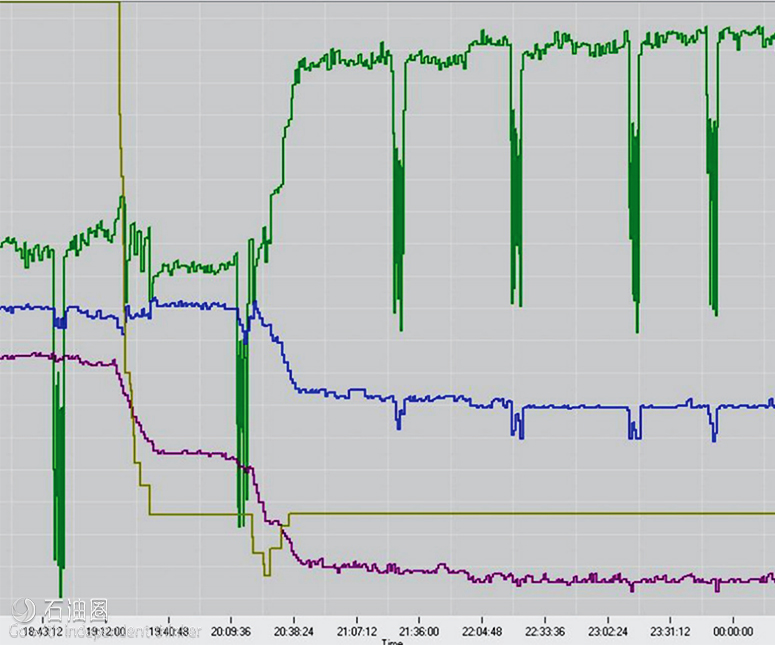

Pressure regulation was introduced to the pulse signalling to ensure data transmission over the large range of flow rates.

Project Results

The system remained highly effective with less than 0.5bar pressure pulses for 428 days. The gauge was

retrieved and found to be in excellent condition.

石油圈

石油圈