Halliburton unveils advanced imaging and borehole inclination service for improving reservoir insight

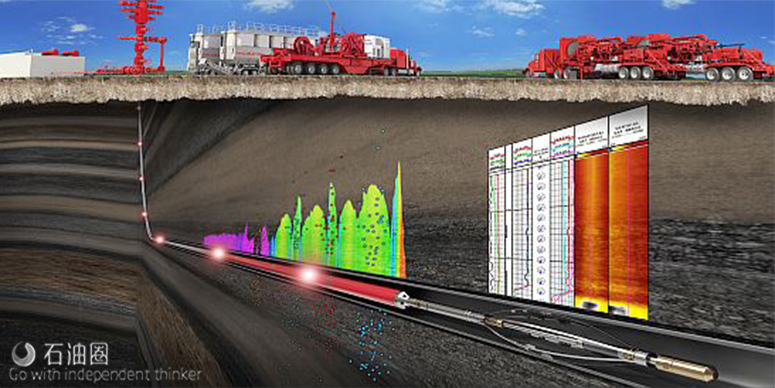

Sperry Drilling, a Halliburton (NYSE: HAL) business, today announced the release of the Radian™ Azimuthal Gamma Ray and Inclination Service, a geosteering solution that provides real-time, high-quality borehole images and continuous inclination measurements. This information helps operators accurately place the wellbore in the sweet spot for increased production and lower costs per BOE in unconventional plays.

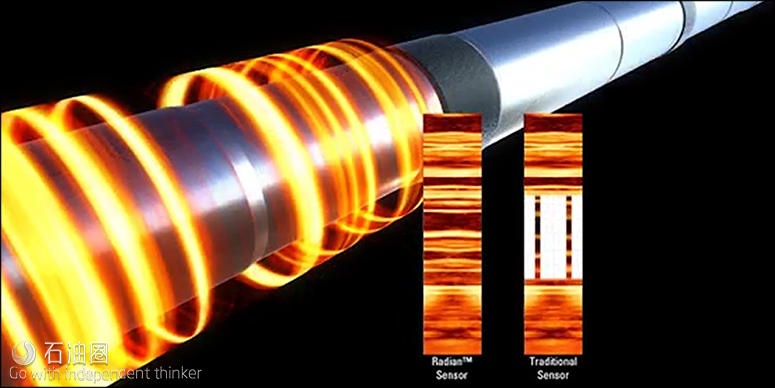

The Radian service utilizes four highly sensitive gamma-ray detectors arranged evenly around the circumference of the tool to generate real-time azimuthal images, whether rotating or not, for greater reservoir insight. This provides operators with enhanced data to assist in real-time geosteering decision making for optimal well placement and better reservoir contact, even when drilling with a mud motor. The optional inclinometer package continuously monitors the orientation of the well and helps minimize wellbore tortuosity.

The Radian tool design is compatible with all drilling systems, including high-torque motors and rotary steerable systems. For maximum flexibility, the tool can run standalone or positioned anywhere in the bottom hole assembly in combination with any Sperry Drilling M/LWD service. Applications include high-pressure, high-temperature environments up to 20,000 psi (138 MPa) and 347 °F (175°C).

With our Radian™ service, you’ll be able to:

Reduce uncertainty by easily distinguishing between formation layers with low gamma-ray contrast

Optimize wellbore placement by knowing your reservoir’s geological structure

Maximize reservoir contact by getting a clear view of the surrounding geology while in rotating or sliding mode

Decrease wellbore tortuosity by obtaining immediate feedback on steering decisions, making it easier to run casing and completion strings

Case:

Azimuthal gamma-ray images uncover stratigraphic features in a seemingly featureless unconventional reservoir

Challenge – Unconventional resources are often costly to produce as a result of the need for hydraulic fracturing. In order for these shale plays to be considered economical, drilling costs must be kept to a minimum, and many operators drill and geosteer wells with only average gamma-ray measurements obtained from a logging-while-drilling (LWD) tool. While the Three Forks formation has sufficient gamma-ray character to effectively geosteer, the wellbore placement in the Middle Bakken formation can be more challenging because of the limited gamma-ray variation, making it difficult to interpret structural changes along the wellbore and to refine the structural map.

Solution – At the recommendation of Sperry Drilling, the operator drilled two wells using the Radian™ azimuthal gamma and inclination tool. The Radian tool features four scintillation detectors spaced 90° apart that allowed for gamma-ray imaging while rotating or sliding, along with an inclinometer that provided continuous inclination measurements for real-time monitoring of the well trajectory. Even with low gamma-ray variations in the formation, the target zone can be precisely identified based on the superior gamma-ray images provided by the Radian service. In addition, the Radian tool allowed for an enhanced survey based on the continuous inclination data for a more accurate structural map. A stratigraphic correlation between average (non-azimuthal) gamma-ray measurements and the enhanced survey was performed on one of the two wells in real time. Real-time interpretation of Radian data made it possible to detect the stratigraphic movement of the wellbore, where bulk gamma-ray measurement was featureless.

“We developed the Radian service to provide operators with greater reservoir insight compared to traditional gamma ray tools,” said Lamar Duhon, vice president of Sperry Drilling. “In collaboration with our customers, we engineered this solution to deliver real-time, high-quality gamma-ray images to help our customers make better geosteering decisions for optimal wellbore placement and maximum reservoir contact. It is aimed at helping operators achieve greater production and lower costs especially in unconventional reservoirs.”

石油圈

石油圈