SPE Offshore Europe 2017, the country’s leading E&P event, takes place Sept. 5-8 in Aberdeen, U.K. The following is a sampling of some of the new technologies and products that will be showcased at the conference this year.

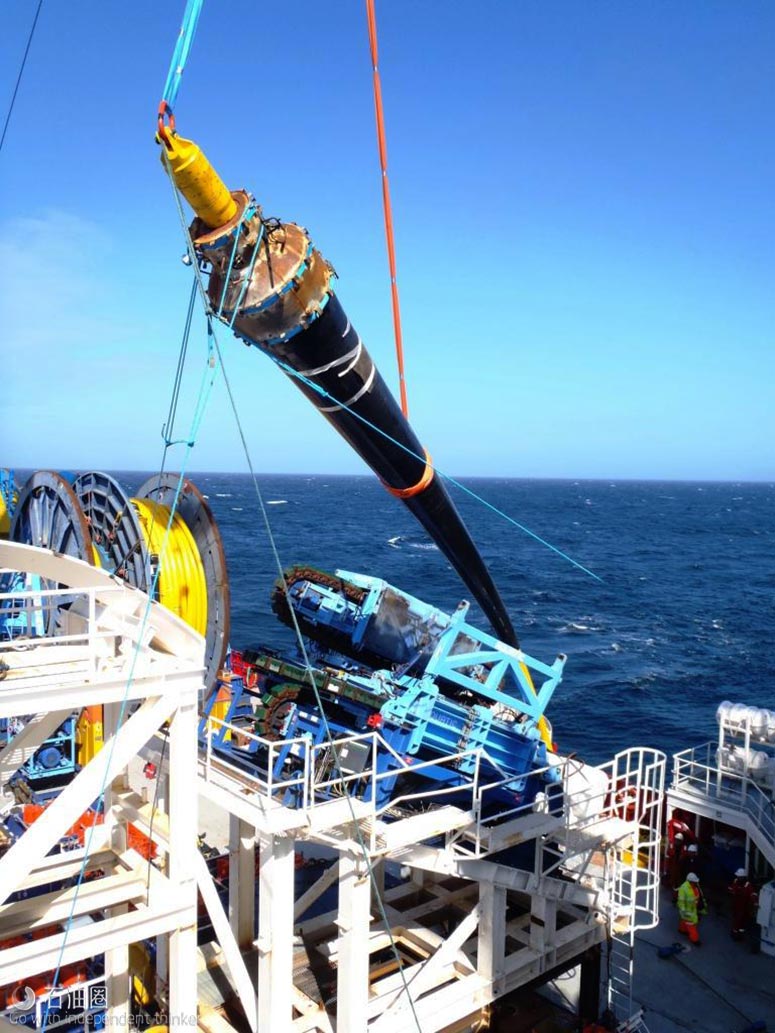

Bend stiffeners fit for the future

Polyurethane bend stiffeners are used to support flexible pipe, umbilicals and cables when connected to rigid structures or a floating production system where there is a requirement to control the minimum bend radius of the pipe. Two types of stiffener are generally available, dynamic and static, and are typically conically shaped polyurethane moldings with a cylindrical bore that slips over the pipe, umbilical or cable. In dynamic applications bend stiffeners require sufficient fatigue resistance to control the in-service bend radii and sustain the cyclic loads to the end of the specified life, whereas in static applications they protect against gross overbending. Balmoral Offshore Engineering’s dynamic bend stiffeners are accredited by Bureau Veritas to American Petroleum Institute 17L1:2013 standards using specifically formulated polyurethane materials to suit applications that are subject to cyclic and dynamic loading. Static stiffeners are largely used for installation purposes.

Cutting costs with late-life asset management

At Offshore Europe Frazer-Nash will be showcasing how it can help oil and gas companies get maximum value from their assets and achieve the best balance of costs, risks and performance. The company will be focusing on the tools it provides around late-life asset management and decommissioning. Late-life field management is critical to the continued safe and profitable operation of oil and gas assets, and Frazer-Nash helps businesses drive down the costs associated with through-life maintainability, latelife operations and end-of-life activities. The company’s independent advice and advanced engineering analysis is designed to enable companies to improve their safety, efficiency and performance, which minimizes their risks and reduces their costs and liabilities. Frazer-Nash aims to answer to the toughest challenges across both greenfield and brownfield developments.

Record pressure, temperature above and below plug

Immediate and reliable verification assurance of a barrier is of significant importance to an operator for safety and operational efficiency. The benefits of proving both the plug and the wellbore’s integrity in a documentable way provides significant cost and time savings to the operator. The wireless Barrier Verification System (BVS) was developed to meet the demand for documentable integrity assurance. The BVS consists of a pressure sensor with a wireless transmitter attached below the barrier. The receiver is included in the setting tool above the barrier to be tested and wirelessly records the pressure from below the installed barrier. An additional pressure sensor in the receiver forms part of the tool to provide an accurate pressure across the established barrier. The system can be configured as a memory readout on slickline or as real-time data on E-line directly to surface. Because the BVS is easily adapted on either intervention method, this adds significant time savings to relatively low-cost wireline operations.

Gas detection instrumentation to be displayed

Ion Science will be showcasing a wide range of gas detection instrumentation at SPE Offshore Europe 2017 at booth 5D101, including its Titan continuous benzene-specific monitor for the accurate detection of ambient benzene in petrochemical applications and the Falco series of fixed continuous volatile organic compound (VOC) monitors with typhoon technology for added reliability in condensing atmospheres and extreme weather conditions. In addition, the company’s wellproven Tiger handheld VOC detector, Cub personal photoionization detector, Tiger Select benzene and total aromatic compound detector, and the entry-level Tiger hand-held VOC monitor will be on display. Ion Science’s Falco series of fixed continuous VOC detectors ensures the ongoing protection of workers operating in potentially hazardous industrial environments such as refineries, petrochemical plants and laboratories. The instrument’s typhoon technology is designed to prevent condensation forming on the sensor and removes the risk of the system short-circuiting.

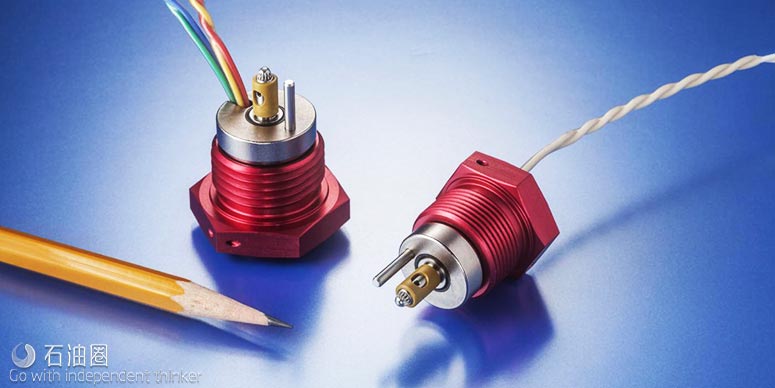

Latching solenoid valve for downhole applications

The Lee Co. has released its new latching solenoid valve for power-sensitive downhole applications. By incorporating magnets into the coil design, the solenoid valve offers a dramatic reduction in overall power consumption, particularly when operating with extended “on” periods. Unlike a traditional coil design that requires continuous voltage to energize the valve from its natural state, the latching valve requires only momentary pulses of 14.5 watts to switch to and remain in each state. The polarity of voltage dictates the position. Lee’s latching solenoid valve draws on the design elements of the company’s ultracompact and field-proven piloting solenoid valves. The Lee MultiSeal simplifies port layout, offers significant space savings, reduces machining costs and provides reliability over traditional sealing methods. The Lee Co. offers custom configurations to meet envelope, material, flow, pressure and electrical requirements for a wide variety of applications.

Assess the readiness levels of new innovations

At Offshore Europe Lloyd’s Register (LR) will showcase its latest Technology Qualification Guidance Note, which has a major role to play in young and unproven components, processes or systems with a lack of historical data. For the investor or insurance provider, this is a good way to assess the readiness levels of new innovations against the investment that needs to be made. Cost-conscious decommissioning is a big feature at this year’s event, and LR has built a virtual reality environment to help illustrate the need for a continued focus on safety and risk assessments in the industry. A new set of services has been launched that includes clarity on emerging threat patterns designed to help clients understand how cyber secure they are and what level of security they want to achieve in the future—an offering with QinetiQ. Collaborative innovation and data technology will play a vital role as industry leaders embrace change and knowledge transfer to maximize economic profitability, especially as fields reach their late-life stage. For more information, visit LR at Offshore Europe 2017 at booth 2C121.

Effective flow control during well cleanup operations

Produced debris in well cleanup operations can create the potential for damage to downstream equipment, including choke valves. This can affect the ability to control the well’s flow, compromise the safety of personnel and result in costly delays and equipment replacement. Master Flo Valve Inc. has developed a patent-pending impact-resistant hybrid-type trim for well cleanup chokes. The trim combines the impact resistance of high-strength steel with erosion-resistant sintered tungsten carbide for erosion control. Since its introduction, the new trim has delivered significant time and cost savings by effectively maintaining flow control and protecting downstream equipment in well cleanup operations with excessive produced debris. For more information on the new well cleanup trim, visit Master Flo Valve Inc. at booth 1J89 at Offshore Europe 2017, where the trim will be on display.

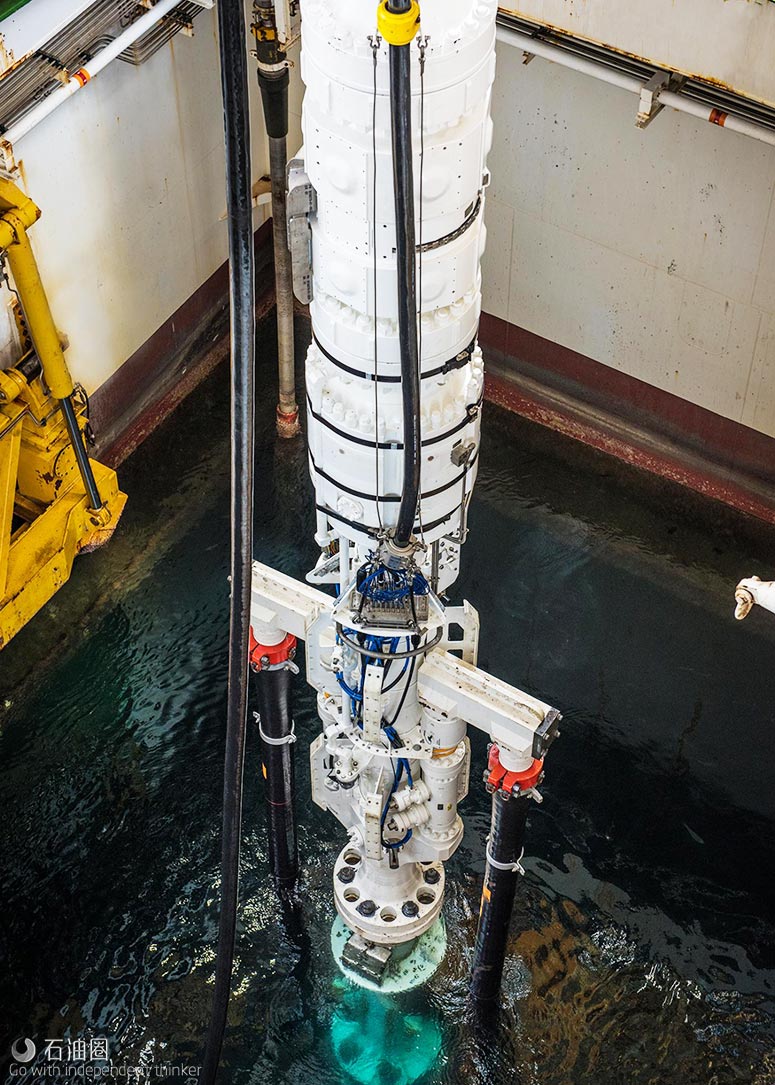

Equipment supports subsea well intervention operations

The Subsea Well Response Project is collaborating with Oil Spill Response Ltd. to procure offset installation equipment. This equipment is an industry first and is designed to support subsea well intervention operations in scenarios where conditions prohibit direct vertical access to a wellhead. In the event of a subsea well incident, this new equipment enables members to remove or install capping or related equipment from a safe offset distance from an incident site. The offset installation equipment includes a carrier with adjustable buoyancy provided by ballast tanks. Positioning is controlled through mooring and pennant lines. It also can be fitted with shears to support debris clearance operations. The equipment has a working depth range of 75 m to 600 m (246 ft to 1,968.5 ft) and the ability to be deployed up to 400 m to 500 m (1,312 ft to 1,640 ft) offset from an incident well.

Evaluate upstream oil and gas assets, companies and portfolios

Among Rystad Energy’s latest product offerings is the new valuation tool UCube Economic Model (UCube EM). UCube EM is an alternative way to access the Rystad Energy proprietary database, UCube, and allows users to access production and economic details for more than 65,000 oil and gas assets. UCube EM is a fully customizable, transparent Excel-based model for evaluating upstream oil and gas assets, companies and portfolios across the world. This tool is especially important when oil and gas markets experience uncertainty. UCube EM allows users to easily adjust all asset-level inputs to understand the effect of changing oil prices, costs, production rates or fiscal regimes on the valuation of upstream companies and assets.

Optimization of challenging MPD operations

Operators needing to perform managed-pressure drilling (MPD) operations encounter a unique set of challenges. The objective is to effectively change downhole pressure via surface pressure, saving time and money by eliminating the need to “weight up” or fight losses before drilling ahead. Additionally, well monitoring and pressure control is managed during tripping to minimize stuck-pipe events or surge and swab. An all-encompassing, original-equipment-manufacturer (OEM)-integrated MPD system from Schlumberger addresses these challenges and includes design, engineering, manufacturing, system integration, well engineering and onsite well delivery services from one supplier. A single point of contact ensures 100% accountability. The MPD control system can be precisely scaled to customer needs or specific well demands per level of well complexity, and it is designed to eliminate extra runs and improve well productivity as a result of reduced formation damage. The system also features enhanced kick detection to reduce environmental impact.

石油圈

石油圈