眼见为实。当地下的油藏密码被技术破解时,也就没那么神秘莫测了。

来自 | E&P

编译 | 张德凯

在页岩勘探数据的帮助下,油藏模拟的作用变得非常重要。在勘探得到数据范围内,利用高级计算机模型,可得到准确的生产数据预测结果。

测井工具的应用也进入了新的时代。套管井测井不仅能提供油气饱和度信息,还能识别未钻遇甜点及有压裂开采潜力的地层。此外,测井数据模拟也逐渐发挥了重要作用,主要是利用MWD/LWD数据模拟裸眼井水平段情况。

油气行业对于这些新技术的接受大大提高了页岩开发效率,同时还提高了油藏的采收率。以下为油藏标准方面最新技术和工具。

填补地球科学与工程学的代沟

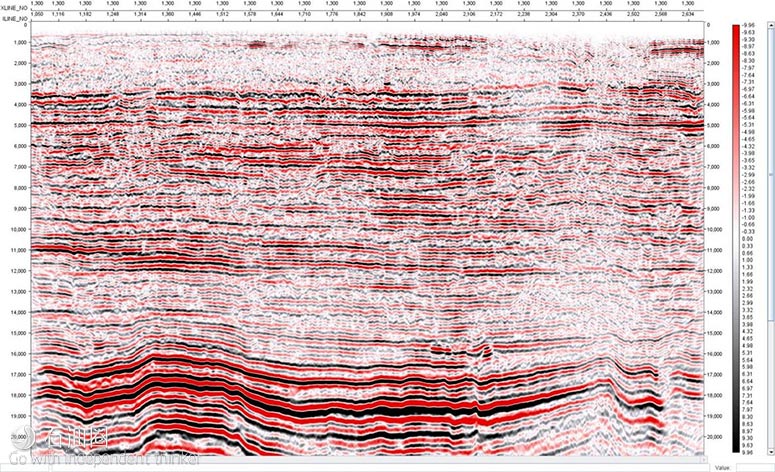

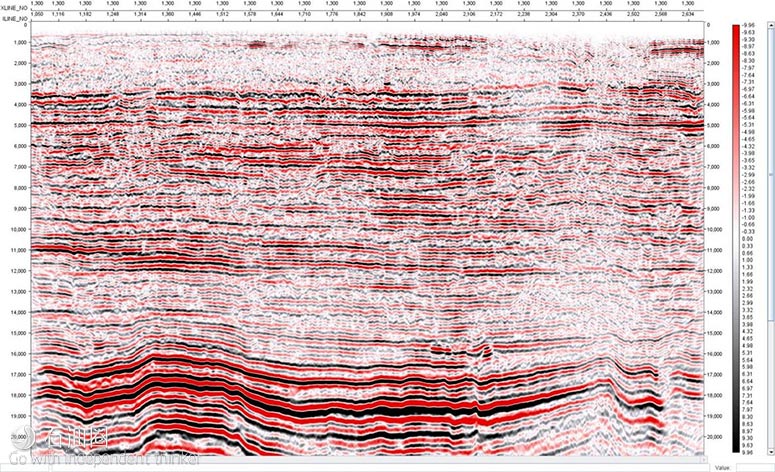

FairfieldNodal公司Delaware盆地项目数据,经过各向异性叠前深度反演,不仅能提供清晰图像,还能提供AVO信息,保证振幅、偏振和角度信息满足后期Ji-Fi反演

Ikon Science公司利用地球科学技术描述非常规油藏,在钻井作业进行前优化油藏开发策略。目前,Ikon已成功将多种关键技术融合,包括地震反演、岩石物理及岩土力学分析等。在最近的Permian盆地测试中,Ikon根据地震反演数据预测了地层起始破裂压力,并通过钻井诱发裂缝的成像测井证实了预测的准确性。Ikon的核心技术是节点抗阻和沉积相反演技术(Ji-Fi),是Ikon与CSIRO公司合作的研发成果。此外,Ikon还与业内领先的岩石物理公司合作(包括Lev Vernik),开发了一套专门用于描述非常规油藏的工具。

Ikon技术研发的目的是弥补地球科学与工程学的差异,将二者有机结合,以期望可以完成井筒位置选择和完井方案设计。其中,地震勘探数据是油藏位置信息获得的关键,地震勘探数据还可用于推倒岩层物理性质,进而用于地质力学模型的建立。在掌握了应力分布和岩石性质后,即可准确预测钻井地点岩层的岩土力学性质。此外,Ikon Science与FairfieldNodal公司已达成合作意向,将于今年就振幅与偏振(AVO)地震成像及量化解译方面合作,这无疑是页岩油藏获得的又一发展契机。

综合性服务降低开采成本

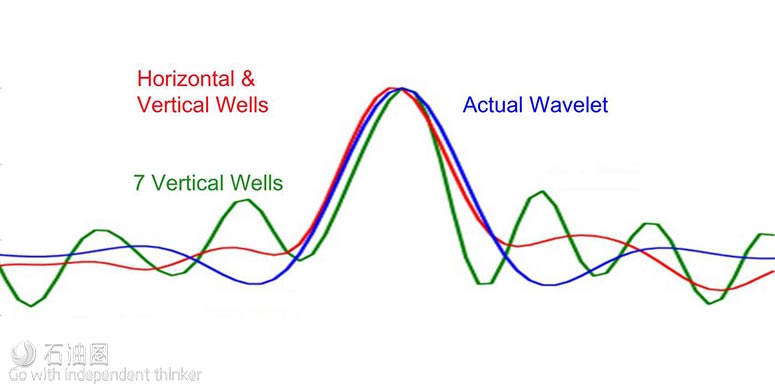

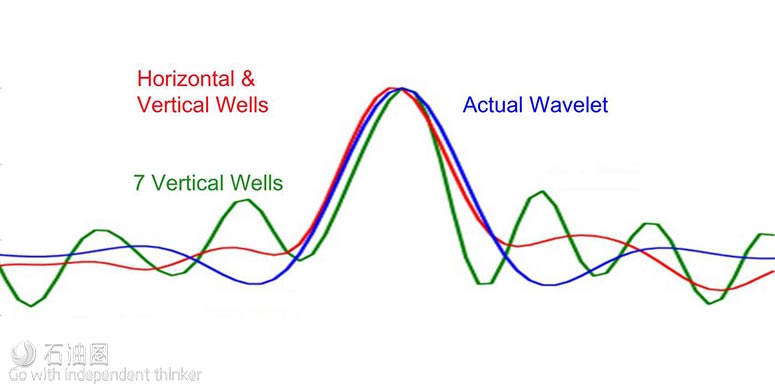

由Quantico模型得到的微波与纵波、纵/横复合波的比较

Quantico Energy Solutions近期推出了一种综合测井服务,该公司负责人表示,该服务能够降低成本和裸眼井测井作业风险。与常规测井方案下入LWD工具、泵入牵引工具不同,Quantico的新型方案使用动态钻井数据和MWD γ射线模拟中子、密度和声波测井,且保持准确性与常规方案无异。通常来讲,裸眼水平井测井作业时间为裸眼垂直井的十倍,这也使得裸眼水平井的测井作业显得不切实际。Quantico的测井方案在此方面取得了重大进步,水平井段地层信息获得所耗费时间缩短到垂直井测井水平,掌握了水平段地层信息,开发商就能提高地质模型的准确性。在之前的一个应用案例中发现,水平井的测井校正数据要比垂直井多20~40倍,无法获得准确数据自然增加了水平井作业风险。

结合Quantico综合测井方案得到的岩层机械性质、渗透率等数据,页岩油藏模型就会更为详细,更易发现油气甜点。岩层压缩强度是测井的重要结果之一,对于提高钻井效率非常重要。Quantico综合测井方案能够将地震勘探数据的准确性指数级提升,勘探声波更加稳定,地震反演结果更加准确。综合测井方案还能量化声波速率和岩层的各向异性,消除了最多50%的声波迭代计算,可节约几个月的深度反演数据处理时间。

新型生产预测数据库,涵盖所有活跃页岩井开采数据

图中所示为俄亥俄州中部Utica 地区TGS公司的Freeport 3-D地震勘测数据,气泡大小代表产量数据。EUR预测结果在最右,图中还结合了经济数据以及日产量分析数据。日平均产量(由气泡大小代表)非常直观的显示了EUR的分析结果。上图还清晰的显示了Utica地区由油到气的开采趋势,即西部为主要产油区,而东南地区则其产量更高。

TGS的生产预测数据库涵盖了美国所有生产井的数据,包括月平均产量及总产量等。如果将这些数据与桌面可视化工具Longbow相结合,只需几分钟即可建立所有的EUR预测模型。新型预测引擎以TGS井筒性能数据库为基础,根据历史生产数据,即可得到所有活跃页岩井的未来开采曲线。其中生产曲线是由双曲线拟合法得到,此外该预测模型还采用了扩展卡尔曼滤波器(EKF),预测结果更加准确。在曲线建立过程中,EKF着重处理近期数据,通过一系列的矩阵方法识别产量变化趋势、及时调整曲线建立逻辑,提高了整个过程的效率和准确率。这也是目前为止EKF理论在油气生产预测方面的首次应用,具有划时代的意义。

识别油气甜点,优化压裂方案

有效的重复压裂作业应该以合理的压裂目标井段选择开始。威德福的Raptor 2.0裸眼井油藏评价系统结合生产测井数据,能够帮助开发商识别待压裂地层,并根据当前开采状况和生产潜力对压裂候选地层进行评估排序。相比于常规的双检测器脉冲中子工具,Raptor 2.0的灵敏度更高(2.5倍),获得的油气数据更准确。与常规工具获得油藏的宏观性质不同,Raptor 2.0获得的未开采油气甜点数据更精确。

Raptor 2.0不仅能指导开发商选择合适的压裂地层,还会详细提出快速提高产量的具体开发方案,同时可保持压裂成本基本不变。Raptor 2.0对于非常规油藏低孔隙率地区尤其适用。该系统采用了配置了四个大型检测器,提高了碳、氧和sigma射线光学的信号强度,并且对碳氢化合物高度敏感,尤其是气体。Raptor 2.0与现有生产测井及衍生工具可配合使用,在实际应用中,一次下钻即可完成Raptor 2.0检测,对于重复射孔、重复压裂及其他增产方案来说,即可降低修井成本,还能减少停井时间。

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

柠檬:186-2292-2332;weiyameng@fonchan.com

二丫:131-3255-0596;zhanglingyu@fonchan.com

For English, Please click here (展开/收缩)

With the wealth of data available in the shale plays, modeling is playing a larger role. Companies are able to use advanced computer mathematics to provide production forecasts within seismic datasets.

Logging tools are also getting a new look. Cased-hole logging helps operators find bypassed pay and identify refracture candidates while providing definitive oil and gas saturation information. And logging simulation is using MWD and LWD data to simulate openhole logs in horizontal sections.

Industry adoption of these new techniques will result in more efficient shale development and greater recovery.

The following is a sampling of new technologies and products for reservoir characterization.

BRIDGING THE GAP BETWEEN GEOSCIENCE AND ENGINEERING

Ikon Science leverages geoscience technology to characterize unconventional resource plays ahead of the drillbit and optimize development strategies. Ikon has integrated several key technologies including seismic inversion, rock physics and geomechanical analysis. Recently in the Permian Basin the Ikon team successfully predicted fracture initiation pressure from seismic and validated those predictions using drilling-induced fracture observations in borehole image logs. Ikon’s main seismic technology is joint impedance and facies inversion (Ji-Fi), developed in collaboration with CSIRO. It also is working with industry leaders in rock physics, including Lev Vernik, to develop tools explicitly for characterizing unconventional resources. Ikon’s technologies are focused on bridging a gap between geoscience and engineering, answering direct questions about well placement and completion design. Seismic data provide an important source of spatial information. Physical rock property information can be extracted from the seismic data that can be used as input for geomechanical models. By understanding the stress regime and rock properties, geomechanical behavior of the rock at prospective drilling locations can be predicted. Furthermore, the 2017 alliance between Ikon Science and FairfieldNodal will provide a combination of amplitude vs. offset (AVO)-compliant seismic imaging and quantitative interpretation technology that will undoubtedly lead to some interesting results for shales.

SYNTHETIC SERVICE REDUCES COSTS

Quantico Energy Solutions has developed a synthetic logging service that reduces the cost and risk of obtaining openhole logs. Rather than running LWD, pump-down or tractored tools, the drilling dynamics and MWD gamma can be used to simulate neutron, density and sonic logs with the same accuracy as conventional logging tools. With openhole horizontal logs typically costing 10 times that of vertical logs, horizontal logging is impractical for most operators. Quantico’s logs provide rock property information along the horizontal well at a similar cost to logging vertical wells. Operators can use the horizontal properties to enhance their existing geological models. A case study demonstrated that a typical horizontal well has 20 to 40 times more calibration data in a landing zone than a vertical well. Incorporating derived properties such as rock mechanics or permeability creates significantly more detailed shale models to better target production sweet spots. Mapping compressive strength can significantly improve drilling efficiencies. The order of magnitude increase in well-to-seismic calibration points provides more stable wavelets for seismic inversions and thus greater resolution. Quantico’s process also quantifies velocity and layer-specific anisotropy across a region, leading to the elimination of up to half of the velocity iterations, which can reduce processing time by several months for depth migrations.

NEW PRODUCTION FORECAST DATABASE INCLUDES ALL ACTIVE SHALE WELLS

The TGS Production Forecast Database is a library of every well in the U.S., containing both a monthly production projection and an EUR total. When combined with the Longbow desktop visualization tool, entire EUR basin studies can be built in minutes. This forecast engine leverages the TGS Well Performance Database to create forward production curves for all active producing shale wells derived from historical production data. Curves are generated using hyperbolic fitting, but this model’s advantage includes extended Kalman filter (EKF) techniques incorporated into the process. EKF techniques emphasize the most recent data, identify trends and adjust logic on the fly using a series of matrix math techniques and results in improved efficiency and accuracy. It is the first time to the developers’ knowledge that the EKF theory has been used in oil and gas forecasting.

DEFINING BYPASSED RESERVES AND IDENTIFYING REFRACTURING CANDIDATES

A profitable refracturing intervention begins with proper candidate selection. Combined with production logging, the Weatherford Raptor 2.0 cased-hole reservoir evaluation system helps identify and rank refracturing candidate wells by determining the existing flow profile and identifying unproduced intervals behind the casing. With 250% more sensitivity than standard two-detector pulsed neutron tools, the Raptor 2.0 system delivers definitive oil and gas saturation data. Rather than a generalized interpretation of the reservoir, the system finds and defines bypassed oil and gas volumes to within a few saturation units. These logs not only guide operators in selecting refracturing candidate wells, but they also give a precise roadmap to quickly increase production with standard cost-efficient perforating. Raptor 2.0 technology is well suited to the low-porosity environments in unconventional reservoirs. The system features a large four-detector array that enhances spectroscopic carbon-oxygen and sigma measurements and is highly sensitive to all hydrocarbons, especially gas. Fully compatible with production logging and many other formation evaluation technologies, the Raptor 2.0 system reduces workover costs and downtime with a single-run candidate-selection option for reperforation, restimulation and other production- management operations.

未经允许,不得转载本站任何文章:

石油圈

石油圈