众所周知,稠油的陆地油田开采及分离、储运等处理已进行了多年,业内在该方面也积累了雄厚的技术和先进的经验,但与之形成鲜明对比的是,在深水等复杂井况下的稠油处理还是业内一个难以逾越的挑战。

其中难度最大的一点就是油/水的分离,油/水的密度差异小,而且稠油的黏度相对于常规原油要高很多,这为稠油的开采带来了巨大困难。常规的静电水分离装置效率较低,经济效率低,也无法应用于偏远作业地区。近年来,一项新的内嵌电子液体聚结器(inLine electroCoalescer)技术逐渐进入人们的视野。

内嵌电子液体聚结器能够显著提高乳化油体中水滴的聚结效率。这项技术有望颠覆下游行业的稠油分离现状,带来革命性的改变。油/水混合物通过电场的作用,处于离散状态的水滴带有极性,而后水滴会改变在电场中无规则的运动状态。这样,水滴相互靠近,逐渐聚结成更大的水滴,从操作的角度来看,更大的水滴更易于分离,整体的油/水分离效率就会得到显著的提高。

该装置可以用于提高现有油/水分离系统的整体分离效率和稳定性,同时还能减少能量消耗和化学药剂用量。毫无疑问,无论将该设备安装在水下或者地面,下游用于分离油/水的设备必定会减少,从而降低整体操作成本,提高经济效益。石油圈原创www.oilsns.com

FMC 的 InLine ElectroCoalescer 技术

FMC公司的 InLine ElectroCoalescer 就是新型油/水分离装置的杰出代表,经验证,FMC的分离装置能够有效的对中质、重质稠油进行高效的油/分离,最大化原油含量。InLine ElectroCoalescer 具有管式结构,结构紧凑,在工作时通入高频、高压交流电产生电场,用来聚结水滴,以便加速下游装置进一步油水分离。

在新井的完井过程中,通过在上游生产装置安装InLine ElectroCoalescer能够显著提高分离装置的分离能力。对于老井和旧的分离装置,该设备能够解决生产瓶颈,减少乳化剂的注入量,降低油/水分离过程中的热量损耗。对于还未开发到油田,适用该装置意味着更下的分离设施和更少的乳化剂使用量,对于环境和收益都有好处。

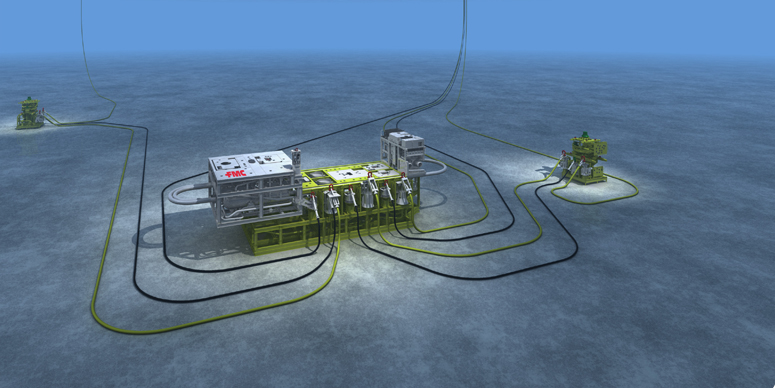

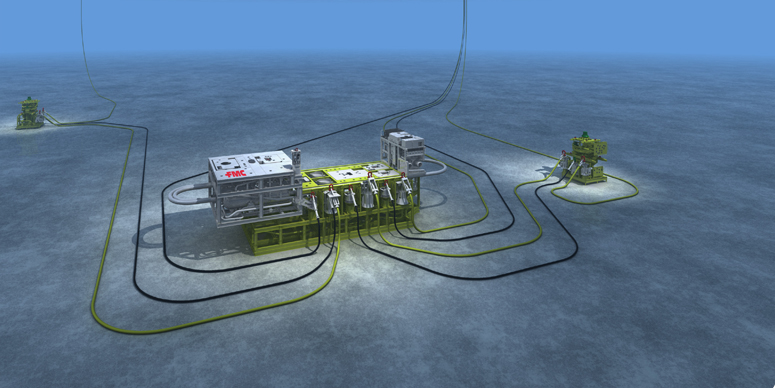

FMC的InLine ElectroCoalescer 装置结构紧凑,相对于其他常规的电子液体聚结器,该设备大小和质量仅为25%—50%,如此的紧凑设计使得该设备具有其他设备不具有的优势。较小的装置和重量使得该设备可以安装在深水原油输送系统,这样就能够实现原油的长距离无水管道输送,降低了能量损耗。

产品特性及优势石油圈原创www.oilsns.com

- 耐高温,最高工作温度200°C,能够满足大多数工作要求;

- 耐高压,最高工作压力100bar;石油圈原创www.oilsns.com

- 结构紧凑,轻便设计,安装简便;

- 降低分离装置的体积和重量,为海上平台操作节省空间;

- 特殊的电场设计,对于黏度不高于30cP的原油都能有效的分离;

- 减少乳化剂和加热装置的使用;

- 可扩展应用。石油圈原创www.oilsns.com

如需获取关于该技术的更多资料,请联系石油圈技术运营 惊蛰,QQ:2582825239。

来自/FMC Technology 译者/Lemon 编辑/Lemon

Although heavy oil has been processed onshore successfully for many decades, processing heavy oil in deepwater, subsea, or Arctic fields is extremely challenging. One key challenge is oil/ water separation, in which physical separation is constrained by the high viscosity of the crude and the narrow density difference between oil and water. Installing conventional electrostatic coalescers or dehydrators is often not economical or is impractical at remote locations. As part of ExxonMobil’s subsea program, several different separation technologies have been investigated and tested that could enable development of these fields. One example of such a technology is an inline electrocoalescer device.

An inline electrocoalescer device enhances the coalescence of water droplets dispersed in emulsified oils. This technology has the potential to improve the performance of the downstream oil/ water separator considerably. By applying an electrical field to an oil/water mixture, the dispersed water droplets become polarized and reorient themselves in the electrical field. As these water droplets approach one another, attractive forces between the individual water droplets lead to coalescence. Larger water droplets that can be separated faster and more easily in the downstream separation equipment are formed. Such a device can be used to increase the throughput, performance, and reliability of existing oil-processing systems, while reducing the energy consumption and/or use of chemical demulsifiers. In new processing systems, either subsea or topside, deployment of such a device has the potential to significantly reduce the size and weight of the downstream separation equipment, thereby lowering the overall capital expenditure

FMC Technologies’ InLine ElectroCoalescer enables efficient oil/water separation and helps maximize deepwater production of medium and heavy oil. This compact, pipe-based technology uses a high-frequency, alternating current with high voltage to polarize, coalesce and enlarge water droplets, which can then be separated much faster in the downstream separation equipment.

Installing an InLine ElectroCoalescer upstream of a separator greatly increases the capacity of that separator. In older facilities, this results in debottlenecking, reduced demulsifier injection or decreased energy consumption of the heating system. For greenfield applications this means the size of the separator and the use of demulsifiers can be greatly reduced. The InLine ElectroCoalescer is compact itself — one-half to one-fourth the size and weight of other electrostatic coalescers. This reduced size and weight make it ideal for installation in deepwater subsea processing systems, and allow for hydrate-free export of crude oil through long-distance pipelines to a host facility.

Benefits of the InLine ElectroCoalescer:

- Design temperature up to 200°C;

- High pressure operation: design pressure up to 100 barg;

- Compact and lightweight design;

- Reduced size and weight of separation equipment and offshore platform structures;

- High efficiency due to unique power supply principles for oil viscosities up to 30 cP;

- Easily up scalable;

- Reduced demulsifier and heating requirements。

未经允许,不得转载本站任何文章:

-

- Demons

-

石油圈认证作者

- 毕业于中国石油大学(北京),化学工程与技术硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。如需获取更多技术资料,请联系Demons(QQ2582825239;微信15810965891)

石油圈

石油圈