水是万物之源,更是页岩油气持久发展的关键。

来自 | E&P

编译 | 二丫 张德凯

如果你让任何一个在非常规页岩油场的操作工说出一个苦恼他们的最基本问题,那相信至少有一半以上的回答会有关于水。由于有限的淡水供应、公众和监管力度的逐渐增加以及少而且远的废水处理途径,页岩操作工正面临着日益严峻的环境和经济压力。

虽然水力压裂技术促进了美国页岩气资源的开发,但是也大大增加了油气行业的用水量。美国地质调查局的报告表明,在过去的十几年中,压裂作业的平均年度用水量从每口油气井17 .7万加仑增加到了每口油井400多万加仑,每口气井510多万加仑。

华尔街日报曾报道,油气生产商为了降低成本、维持油气供应量,在水资源保护和废水循环利用方面投入了许多金钱和精力。即使在当今低油价的情况下,油气生产商们仍然在努力处理这些废水,不惜缩减其他方面的开支。

技术升级,水管理、处理工艺得到优化

Gradiant Energy Services提供多种水处理工艺,包括游离化合物杀菌、选择性化学分离、游离气体浓缩器等。该方案将盐、水与电力结合,在形成的混合溶液中实现硫酸盐还原菌和生酸细菌的净化。Gradiant Energy Services的杀菌系统可移动,且处理量高达到120bbl/min,通过使用该技术,即可确保开发商重新注入井中或是作用于油藏的废水无菌。

合理的杀菌方案可以长效抑制细菌存在诱发的相关问题,例如H2S腐蚀。选择性化学分离主要用于处理产出水/回流水,之后将处理过的盐水继续用于压裂作业,该技术采用了Gradiant Energy Services公司的特殊算法,得到理想的化学药剂使用量,配合层状澄清器实现废水的净化,目前该装置的最大处理量为10,000 bbl/d。此外,Gradiant Energy Services的气体浓缩器是一种蒸发系统,通过将废水中的游离气体蒸发脱除减少作业现场废水处理体积,能够显著降低废水运输量。同样,该设备可移动,且通过湿法将废水体积减小。在气体的蒸发过程中,Gradiant Energy Services的专利技术(泡罩塔)可有效防止固体颗粒的挥发,气体挥发装置的处理量约为1,000 bbl/d。

新型支撑剂减少产出水量,提高产量

Hexion公司的AquaBond支撑剂全部为树脂涂层沙粒,具有多种粒径规格,包括20/40, 30/50和40/70。相比于常规支撑剂,AquaBond支撑剂颗粒的化学树脂涂层技术能够降低地层水的产出量,同时保持油气产量不受影响。通过减少废水储存、处理量,降低了成本,无形中增加了开发商的收益。除了减少地层水产出这一特点,AquaBond支撑剂的Stress Bond技术同时也具备其他树脂涂层支撑剂的特点,包括支撑剂回流控制、抑制支撑剂碎屑生成、最小化支撑剂嵌入地层以及提高油气产量等。

使用AquaBond支撑剂可有效提高油气产量。正如在Granite Wash区块的应用案例所示,相比于常规支撑剂,AquaBond在12个月的应用中平均提高产量36%,效果非常明显。这些支撑剂通过降低采出水产量,提高油气产量,达到了最大化油田收益、降低桶油成本的目的。目前,AquaBond支撑剂在北美得到了大规模应用,尤其是在产出水多的地区。总之,AquaBond既能降低废水产量及处理费用,又能提高油气产出,开发商收益明显提高。

新型分离系统有效将废水中原油分离

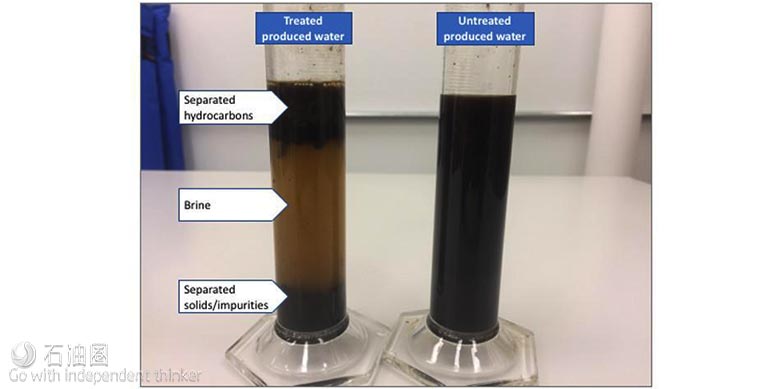

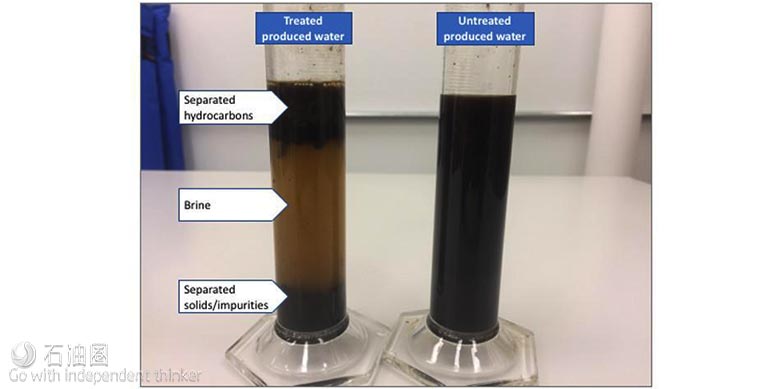

采用微生物技术技术处理前后(2小时)对比图

鉴于非常规油气藏完井、开采等过程的巨大耗水量,废水循环/处理重要性日益凸显。Locus Bio-Energy Solutions LLC利用该公司的专利技术,成功开发了一套微生物废水处理技术,对于分离回流水及采出水中的原油非常有效。该技术环境友好,无污染,在废水回收利用及采出水回注等应用中均有应用。新产品可迅速去乳化废水中夹带的原油,使固体杂质(如结构、细沙等)迅速从盐水中分离。当原油被分离后,只需以机械的方式将其收集,无需担心杂质存在等问题,在以上整个过程中都不适用有毒化学物质,并且操作简单。

水平油水分离罐替代传统卸油罐及转移泵

NOV推出的水平油水分离罐不仅能提高IOR,还能带来其他方面收益。该设备主要用于替代常规/高级垂直油水分离罐,效率更高,在其设计中还充分考虑了压裂回流液及含盐废水处理问题。目前,新型水平油水分离罐在Permian Basin和Marcellus Shale都已得到应用。结果显示,单个水平油水分离器作用相当于多个卸油罐、垂直油水分离器和转移泵。相对于传统的垂直油水分离罐,水平设备的原油回收率更高,且所用时间更短。我们都知道,随着压裂作业频率逐渐增加,废水中的固体含量也更高,这也意味着更高频率的储油罐清洗作业。为了解决这一问题,NOV推出了固体杂质流态化解决方案Tore,可在水平油水分离罐汇总迅速将固体杂质分离,同时不会对油水分离造成影响。此外,水平油水分离罐还结合了NOV的含盐废水优化方案,此前该方案多用于优化废水品质及低杂质原油的获得。如果将NOV的WaterWolf动态原油回收系统与脱砂模块结合,那么整个废水处理过程将会更加的高效。

新型技术有效脱除难溶有机/无机杂质

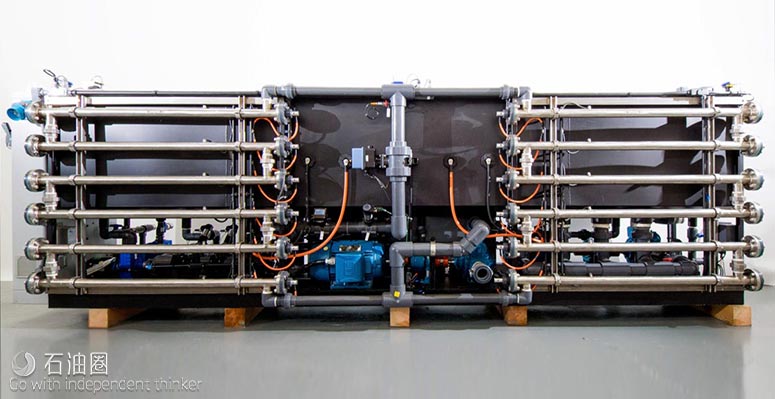

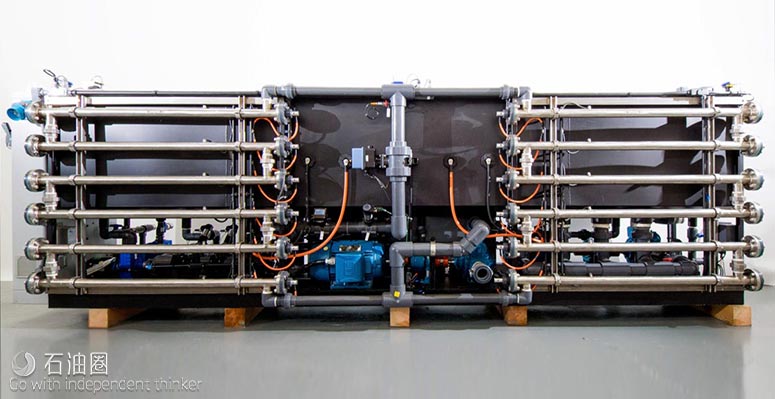

OriginClear公司的Electro Water Separation(EWS)能够有效移除难溶的有机/无机杂质,如采出水中的分散油滴和悬浮固体杂质等。EWS系统主要使用电流与阳极形成电场,打破油/水乳液平衡,使悬浮的固体杂质或油滴聚合并漂浮于水面,之后即可轻松回收利用或直接当作杂质处理。近日,OriginClear公司为EWS新增加了一个模块—Advanced Oxidation,利用原技术的电场可移除废水中可溶性杂质,包括氨、H2S、金属离子及其他难以移除的化学物质。通过EWS的整个处理过程,Advanced Oxidation能够有效杀菌,并将重金属离子及可溶性有机杂质氧化去除。

将以上两种技术结合得到的EWS:AOx是一款模块化、节能、连续且易于操作的废水处理方案。EWS:AOx适用于所有类型废水的处理,由于其处理流程位于过滤器和过滤膜之前,EWS:AOx不仅能提升处理后的水质,还能显著延长其他水处理设备的使用寿命。在实际应用中,EWS:AOx能够Colorado气井废水浑浊度降低99.9%,其他杂质如固体颗粒、碳氢化合物均低于环保标准,在West Texas,Monterey和Niobrara的应用中也得到了相同的结果。

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

柠檬:186-2292-2332;weiyameng@fonchan.com

二丫:131-3255-0596;zhanglingyu@fonchan.com

For English, Please click here (展开/收缩)

TECHNOLOGIES IMPROVE WATER MANAGEMENT, TREATMENT PROCESSES

Gradiant Energy Services offers several technologies, including free radical disinfection, selective chemical extraction and carrier gas concentrator for water management and treatment. Free radical disinfection provides short-term kill for disinfecting water with no hazardous chemical handling. The treatment uses salt, water and electricity to generate a mixed solution that provides effective bacteria kill of sulfate-reducing bacteria and acid-producing bacteria. The treatment is a mobile system that treats water on the fly up to a rate of 120 bbl/min. The technology allows operators to ensure that the water pumped downhole and reaching the reservoirs is properly disinfected and treated. Proper disinfection eliminates the long-term problems that can occur from bacteria growth, H2S and corrosion. Selective chemical extraction is a treatment that takes produced and flowback water and recycles the water back to a clean brine reusable for fracturing operations. The technology uses a patented algorithm to develop the chemical dosaging along with a patented lamellae clarifier. The system is designed to treat 10,000 bbl/d in a modular capacity. In addition, the carrier gas concentrator is an evaporation system that runs off of the operator’s field gas to reduce the volume of water the operator is handling on location, significantly reducing trucking cost. This system also is mobile and reduces water volume by using a humidification process. The amount of particulate matter released in the vapor is minimized through the patented technology, the bubble column. The evaporation unit can evaporate about 1,000 bbl/d.

PROPPANT REDUCES PRODUCED WATER AND INCREASES PRODUCTION

Hexion’s AquaBond proppants, available in 20/40, 30/50 and 40/70 mesh sizes, are an advanced resincoated sand. These proppants use a resin chemistry that reduces the production of formation water compared to traditional proppants while maintaining oil and gas production. This increases the profitability of the well by reducing wastewater storage and disposal costs. The AquaBond proppant’s Stress Bond proppant technology delivers all of the benefits of a curable resincoated proppant, including proppant flowback control, reduction of proppant fines generation, minimization of proppant embedment and enhanced well production, compared to traditional proppants. AquaBond proppants also increase hydrocarbon production, as shown in a recent case study. Results yielded a 36% hydrocarbon production increase over traditional proppants in offset wells in the Granite Wash Formation after 12 months. These proppants are helping operators reduce water, maximize well profitability and lower cost per barrel of oil equivalent. These proppants are being used in multiple basins across North America where minimizing water production is essential. The cost savings to operators combined with the enhanced production will yield improved returns.

TREATMENT SEPARATES HYDROCARBONS FROM FLOWBACK AND PRODUCED WATER

Water recycling and/or disposal is becoming increasingly important in unconventional production due to the massive amount of water involved in completion and production processes. Locus Bio-Energy Solutions LLC has developed a patent-pending microbebased clarification treatment specifically designed to separate hydrocarbons from flowback and produced water. This environmentally friendly technology has applications in both water recycling and in disposal well injection of produced water. The company’s product can rapidly demulsify entrained hydrocarbons and destabilize solid suspension impurities such as scale and sand, allowing them to immediately separate out of the brine. The hydrocarbons can then be mechanically recovered to add to oil sales volume while impurities are filtered out. The treatment is nontoxic and easy to implement.

HORIZONTAL GUN BARREL REPLACES MULTIPLE OFFLOAD TANKS, TRANSFER PUMPS

National Oilwell Varco’s (NOV) horizontal gun barrel offers significant benefits to operators beyond IOR. Designed to be more efficient than traditional or enhanced vertical gun barrels, the NOV horizontal gun barrel is engineered with fracturing flowback and saltwater disposal in mind. Already being adopted in the Permian Basin and Marcellus Shale, a single horizontal gun barrel replaces multiple offload tanks, gun barrels and transfer pumps. The horizontal orientation recovers far more oil with less residence time than a typical vertical gun barrel. Increased hydraulic fracturing activity is leading to more solids in the wellstream, which can mean frequent tank cleanouts. This problem can be eliminated with NOV’s proprietary Tore solids fluidizing technology, which quickly and efficiently removes solids from the horizontal gun barrel without disturbing the separation of oil and water. The horizontal gun barrel also is featured in NOV’s optimized saltwater disposal process, which is designed to deliver better water quality at lower cost and produce cleaner, drier oil. Combined with NOV’s WaterWolf dynamic oil recovery system and desanding skid, the complete suite offers a more efficient option for water recycling.

TECHNOLOGY EFFICIENTLY REMOVES NONSOLUBLE ORGANICS AND INORGANICS

OriginClear’s Electro Water Separation (EWS) technology efficiently removes nonsoluble organics and inorganics such as free and dispersed oil and suspended solids from produced water. The system uses electricity and nondonating anodes to break the oil/water emulsion and coagulate and float suspended solids and oils to the surface of the water so that they can be easily raked off for recovery or simplified disposal. In a recently added final stage called Advanced Oxidation, the electrical fields already generated remove dissolved contaminants such as ammonia, H2S, metal ions and other chemicals that are hard to remove from influent water. Throughout the process, Advanced Oxidation kills bacteria and oxidizes most heavy metals as well as many miscible and dissolved organic contaminants. The combined technology, EWS:AOx, is modular, energyefficient, continuous and easy to manage. It fits right into any water treatment process and works ahead of filters and membranes to improve final water quality and increase the lifespan of all water treatment equipment. EWS:AOx has been demonstrated to remove 99.9% of turbidity and reduce suspended solids and hydrocarbons to below detection limits on produced water from Colorado gas wells, West Texas intermediate wells, and Monterey and Niobrara formations.

未经允许,不得转载本站任何文章:

石油圈

石油圈