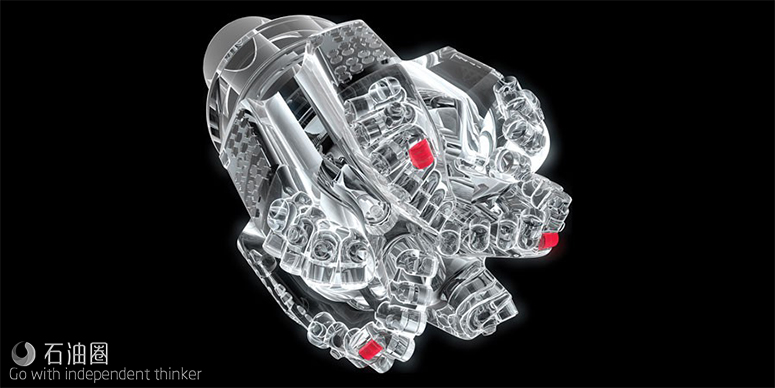

Cruzer™ Depth-of-Cut Rolling Element

Halliburton (NYSE: HAL) today announced the release of Cruzer™ depth-of-cut rolling element, an innovative drill bit technology designed to increase tool face control without reducing drilling efficiency. This provides operators with the ability to increase their rate of penetration (ROP) at a lower cost per foot for improved economics.

The CruzerTM depth-of-cut rolling element is an enhancement feature available on Halliburtons polycrystalline diamond compact (PDC) fixed-cutter drill bits.This proprietary PDC technology is capable of drilling the most challenging formations, with its high level of abrasion resistance, impact resistance, and thermal mechanical integrity (TMI). When the Cruzer rolling element is chosen as a customized add-on by our Local Design at the Customer Interface(DatCISM) team, there is less wear on this depth-of-cut rolling element, thus enabling a more consistent drilling level throughout the bit run.Additionally, the rolling element minimizes the amount of torque needed for the drilling process.

The diamond-and-carbide bearing lowers the coeffcient of friction, ensuring low torque and low heat generation. The material integrity of this bearing keeps the rolling element in place, thus minimizing wear. The rolling element’s small package size allows this feature to be incorporated into existing or new designs. These rolling elements are repairable and replaceable for future runs.

Designed to improve overall drilling economics by reducing torque and increasing ROP, other benefits include durability, steerability, and consistency of results. The Cruzer rolling element is particularly effective in applications requiring more stabilized control of the directional drilling process. This depth-of-cut rolling element incorporates all the latest engineering advancements from Halliburtons research and development labs to meet the complexities and challenges of drilling in today’s environment.

FEATURES

(1)Diamond depth-of-cut rolling element

(2)Small package size

(3)Supports dynamic stability of rotary steerable systems

(4)Optimized placement

BENEFITS

(1)Increases tool face control without reducing drilling torque

(2)Increases average rate of penetration (ROP)

(3)Lowers cost per foot

The Cruzer improves overall drilling economics, and is particularly effective in applications requiring more stabilized control of the directional drilling process.This depth-of-cut rolling element brings you all the latest engineering advances from Halliburton research and development labs. Together, we can meet the challenges of your most complex environment.

石油圈

石油圈