ClearPAC* polymer-free gravel-pack fluids are water-based fluids prepared by adding a viscoelastic surfactant (VES) to a completion brine; a wide range of brine densities can be used. Viscosity develops rapidly and is not prone to shear degradation.

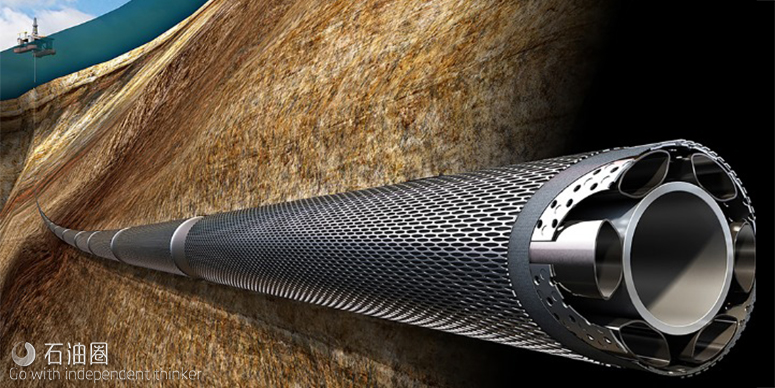

OptiPac screen and antiswab tool eliminate an extra run, saving rig spread costs in a deviated high-temperature well with low fracture gradient, offshore India.

APPLICATIONS

(1)Openhole and cased-hole gravel packing with conventional or Alternate Path†screens;

(2)Gravel packing in circulating or squeeze modes;

(3)Vertical, inclined, and horizontal wells;

(4)Deepwater, continental shelf, and land wells.

BENEFITS

(1)Less risk of premature screenout due to superior gravel suspension;

(2)No hydration time required (continuous mixing);

(3)Enhanced production due to high retained permeability ;

(4)Cost savings because of reduced surfactant amounts;

(5)Longer gravel-packed sections due to low friction pressure;

(6)Further time savings through elimination of subsequent breaker requirements.

Lower surfactant concentration and friction pressure

The fluids provide superior gravel suspension performance and shear recovery at lower surfactant concentrations compared with other VES fluids. They also exhibit low friction pressure during pumping compared with polymer-based fluids, making them ideal for gravel packing long horizontal intervals with Alternate Path screens.

No breaker requirement for viscosity reduction

Unlike crosslinked-polymer-based fluids, ClearPAC fluids exhibit viscosity reduction on contact with crude oils or on dilution with brine. No breaker is required to reduce viscosity after the gravel-pack operation is complete.

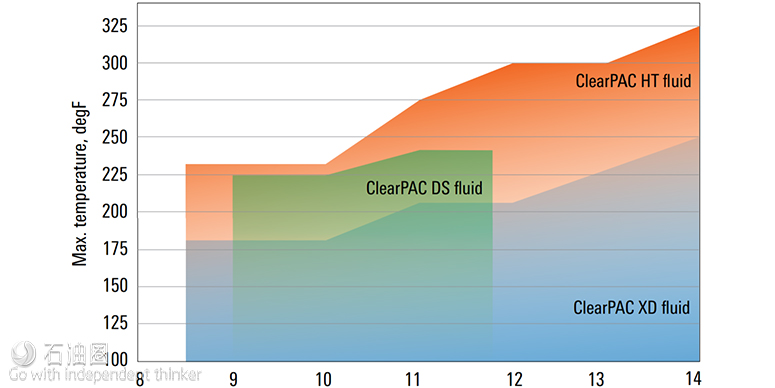

Three formulations for operational flexibility

ClearPAC XD* polymer-free VES gravel-pack fluid is compatible with both monovalent and divalent brines with final fluid densities ranging from 8.5 to 14.0 ppg. It is suitable for operating temperatures up to 250 degF [121 degC].

ClearPAC HT* polymer-free VES high-temperature gravel-pack fluid contains a sand suspension additive in addition to the VES, for improved performance at higher temperatures. It is suitable for operating temperatures from 180 to 325 degF [82 to 163 degC] and compatible with both monovalent and divalent brines with final fluid densities ranging from 8.5 to 14.0 ppg.

ClearPAC DS* polymer-free VES gravel-pack and mudcake-cleanup fluid is compatible with most enzyme and chelating agent solutions. Incorporating these additives enables simultaneous gravel packing and mudcake cleanup where removal of calcium carbonate bridging-weighting agents is required, reducing operating time. Monovalent or divalent brines with final fluid densities ranging from 9.0 to 11.8 ppg can be used. ClearPAC DS fluid is suitable for operating temperatures up to 240 degF [116 degC].

Case Study

Background

Offshore India, a sanded-up gas-producing well with a fracture window of only 600 psi and bottomhole static temperature (BHST) of 236 degF [113 degC] was sidetracked and prepared for recompletion with an openhole gravel pack. The openhole section is 243 ft [74 m], and the well has a maximum deviation of 87° with a deviation of 65° through the reservoir.

Because of the highly depleted nature of the reservoir, the narrow fracture window, and the long horizontal well segment, the operator originally planned for a low-rate gravel pack with specialty ultra-light weight proppant. However, due to unavailability and high cost, the operator elected to use conventional ceramic proppant.

To minimize formation damage, the operator planned to use a conventional viscoelastic surfactant (VES) carrier fluid. However, laboratory testing determined that at the expected reservoir temperature, a conventional VES fluid system was unable to adequately transport the ceramic proppant at the low pump rates required to avoid fracturing the formation. The operator asked for a better option.

Challenge:

Completely pack gravel in the openhole annulus of a high-temperature gas well with high inclination and low fracture gradient without the formation damage risks of a polymer gel fluid.

Solution

Specialty screen and fluid system for efficient gravel packing

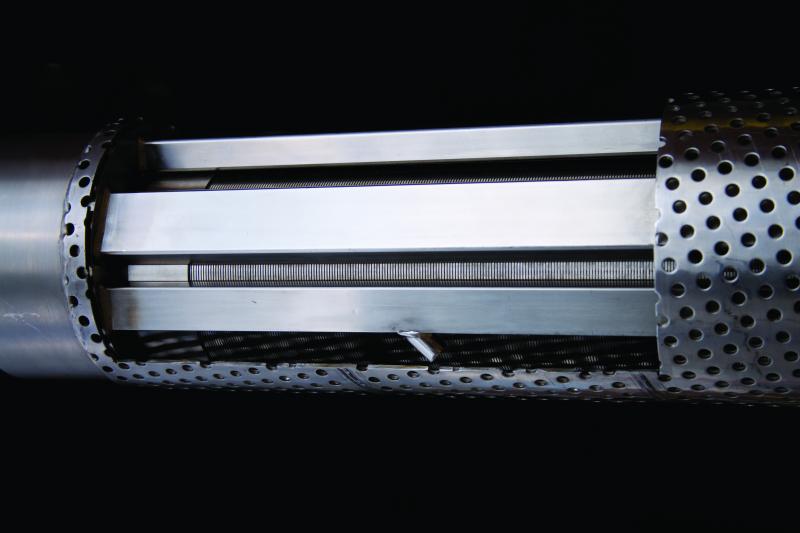

To ensure complete packing of the openhole section, Schlumberger recommended a completion that included OptiPac screens, which incorporate Alternate Path technology with shunt tubes and nozzles to bypass bridges and fill voids that can occur when gravel- and frac-packing in extended-reach wells.

The completion also included an antiswab service tool to enable the successful placement of the gravel and then convert to wash-down mode for the MudSOLV filtercake removal service.

For gravel-packing, Schlumberger recommended ClearPAC HT fluid, formulated for use with screens employing Alternate Path technology at BHST between 200 and 300 degF [93 to 149 degC]. Unlike alternative fluid options for suspending proppant at very low rates in that temperature range, ClearPAC HT fluid is nondamaging and compatible with the relatively inexpensive, locally available calcium chloride (CaCl2) brine. This compatibility improved logistics and lowered fluid costs for the operator.

To avoid fracturing the reservoir with a narrow frac window of approximately 150 psi, careful fluid design was critical to minimize friction pressures and still suspend the gravel. Because of its superior proppant-carrying capability compared with conventional VES at high temperatures, the ClearPAC HT fluid was designed with lower viscosity, which also helped reduce friction pressures. The real-time mixing capability eliminated the requirement for rig tanks or huge tank volumes for batch mixing, thereby saving time on the rig and improving fluid quality.

Complete annular pack and production success

Extensive laboratory testing determined that the fluid could transport conventional ceramic proppant, which enabled the customer to use existing inventory, saving 45% of proppant cost compared with the same volume of specialty lightweight proppant. A full yard test on location in India before mobilization to the rig for the job validated the fluid design and gave a high confidence that ClearPAC HT fluid would transport the ceramic proppant as required and without any issues.

On the drillship, the fluid was prepared in 9.3-lbm/galUS [1.1-g/cm3] CaCl2 brine using skid-based mixing equipment. The openhole gravel pack was pumped at 3 to 4 bbl/min [0.48 to 0.64 m3/min] with 30/50 ceramic proppant at concentrations from 2 to 4 lbm of proppant added [0.24 to 0.48 g of proppant added].

Based on proppant volume pumped, hole size, and memory gauge analysis, the treatment was determined to have achieved a 100% annular pack. Mass balance calculations determined that no proppant settled in the long horizontal workstring section.

After the gravel-pack operation, the antiswab service tool was rapidly converted to wash-down mode for a MudSOLV filtercake removal service, saving approximately USD 450,000 on rig spread costs by eliminating the need for an additional run.

After the service, the well was shut-in for 3 weeks. When it was opened for production, it met production targets. A second well completed in the same field confirmed the new fluid technology and completion design.

石油圈

石油圈