Charting a Bigger Reservoir Picture——Real-time fluid mapping-while drilling service enhances well placement and production potential.

Understanding reservoir fluid properties is a prerequisite to successful field development, especially as wells have become increasingly multifaceted with more deviated and extended-reach trajectories. To meet these challenges, operators are looking for “smart” downhole fluid analysis techniques that provide an accurate, comprehensive picture at all stages of the life of the reservoir—in real time while drilling—to enhance completions and meet production goals.

Traditionally, fluid properties are determined by analyzing samples in a laboratory after the well has been drilled. This after-the-fact approach adds time and does not address the risk of poor well placement. Furthermore, it often results in contamination of the reservoir by the drilling fluid filtrate and leads to production problems due to unknown fluid properties such as the presence of CO2. Moreover, when applied to highly deviated wells, this methodology—unlike assessing fluid composition while drilling—might fail to reduce the risk to well integrity and contribute to the minimization of production potential.

Downhole fluid laboratory

In an effort to overcome these limitations, Schlumberger has developed a reservoir mapping service that delivers highly accurate fluid composition data while drilling to help operators gain a broad and dynamic understanding of the reservoir. Described as a downhole fluid laboratory, the real-time service ensures that wells are optimally positioned to mitigate wellbore risks and results in better productivity during steering and completions to deliver greater production.

Introduced in May 2017, the SpectraSphere fluid mapping-while-drilling service addresses five key objectives:

(1)Maximizing reservoir exposure in real time while drilling;

(2)Staying in the sweet spot;

(3)Proactively refining field development plans;

(4)Boosting production potential; and

(5)Assessing fluid distribution complexities early.

The technology is applicable for any exploration or development well but is especially suited to highly deviated and extended-reach offshore wells, where costs and risks are very high. Newly designed stabilizers can be placed between the modules and repositioned depending on the well profile, reducing the risk of sticking.

Importantly, the fluid mapping-while-drilling service provides the ability to conduct laboratory-quality downhole fluid analysis, including fluid composition and typing, fluid fractions, and gas-oil ratio (GOR) in real time while drilling. The optical spectrometer and resistivity cell monitor both reservoir fluid properties and the cleanup process as fluid is pumped through the flowline.

Petrophysicists, reservoir engineers and drilling engineers can integrate data from various data streams to make correct real-time decisions and continue drilling rather than waiting several weeks for laboratory analysis.

The service was engineered with three modules:

(1)A pretest probe that provides highly accurate measurements of formation pressure and mobility to determine the best spot in the reservoir to analyze fluid;

(2)A fluid mapping module, including a pump-out and a downhole fluid analyzer, which uses spectrometer data obtained from the visible and near-infrared spectrum;

(3)A sample carrier module, which acquires up to 12 pressure/volume/temperature-grade fluid samples in a single run.

The new services were designed to be integrated with the entire family of Schlumberger LWD and surface logging technologies, primarily the GeoSphere reservoir mapping-while-drilling service, which uses deep directional electromagnetic measurements to reveal subsurface bedding and fluid contact details more than 30 m (100 ft) from the wellbore. This technology combination results in a true reservoir structural and fluid map and a unique depth of investigation that expands the envelope for optimizing landing, maximizing reservoir exposure and refining field development plans.

Reliable formation testing

In the Gulf of Mexico (GOM) ENI US Operating Co. used SpectraSphere to acquire and analyze fluid samples in real time and measure formation pressure in a wildcat exploratory well in Mississippi Canyon. The target zone was located at a water depth of 1,767 m (5,800 ft) with uncertain reservoir characteristics and fluid properties. ENI wanted to optimize the formation testing processes to reduce time and cost.

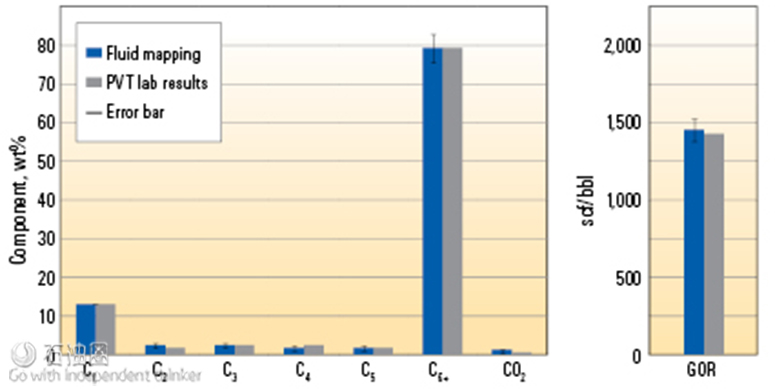

Incorporated into the drilling assembly, the fluid mapping-while-drilling service collected and analyzed six samples downhole in real time, marking the first-time transmission of detailed in situ fluid properties. The service estimated contamination and cleanup time; performed fluid identification and typing; and measured GOR and fluid composition, including C1 to C5, C6+ (methane, ethane, propane, butane, pentane and hexane, respectively) and CO2.

The results were later confirmed by laboratory testing. Contamination was estimated in real time to within +/-2% of the laboratory-determined values. Twenty-eight pretests were taken—17 while drilling and 11 during pullout—providing ENI a comprehensive view of the reservoir pressure and fluid gradients. The service resulted in a time savings of 10 weeks for ENI.

Minimizing sticking in deviated wellbores

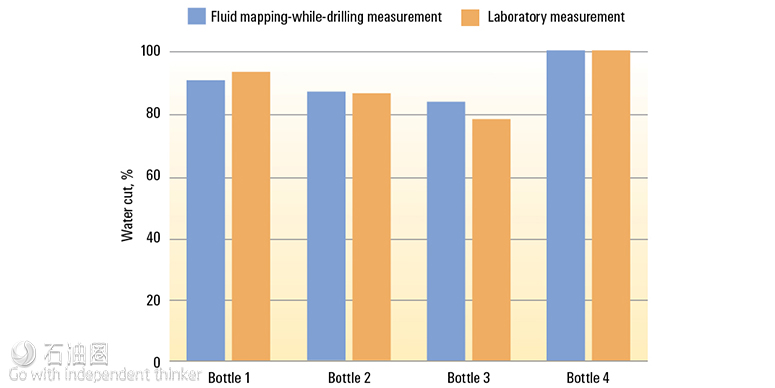

In an offshore field in Malaysia Hess Corp. used the service to acquire reservoir-representative formation fluid and gas samples and formation pressure measurements. The objective was to determine formation water salinity and enhance completion and production planning in highly deviated wellbores that intersected pressure-depleted zones with an increased risk of differential sticking.

The service provided real-time fraction measurements that showed a decrease in the presence of oil-based drilling filtrate, which enabled Hess to begin sampling after the cleanup process. Real-time temperature and resistivity data showed the pumping fluid was representative of the reservoir fluid. Over a 12-hr period Hess collected four fluid samples with less than 1% contamination, two gas samples and 21 formation pressure measurements in one run while avoiding differential sticking. Because subsequent laboratory results confirmed the samples from the first well were representative of the reservoir, Hess eliminated sampling in two additional wells, saving three days of rig time.

Water samples provided increased insight into formation water salinity, which is critical to calculating water saturation, completion optimization design and production planning. Pressure data expanded understanding of zonal connectivity in the field.

Assessing production potential of a reservoir

In the first deployment of SpectraSphere in the Middle East, an operator drilled a multilateral horizontal oil well to assess the production potential of a reservoir in a tight carbonate formation with a historically high risk of sticking. The fluid mapping-while-drilling service and the EcoScope multifunction LWD service verified that a low-permeability section of the reservoir contained movable hydrocarbons, confirming production potential.

Prior to conducting fluid analysis or sampling, Schlumberger performed 16 pretests to obtain formation pressure and estimate mobility for determining the optimal location for the first pump-out station. Initial pretests in the gas zone were taken to optimize the mud weight. After launching the downhole fluid analysis operation at the target depth in the 8 1/2-in. section, hydrocarbon breakthrough was observed significantly earlier than previously experienced in the formation. The observance of some gas in the flowline confirmed the ability of the fluid mapping-while-drilling service to identify different fluid phases in complex flow regimes.

The optimized mud weight and stabilizer design significantly reduced the risk of sticking. This became evident when the bottomhole assembly, which had been on station for almost three hours, was moved with no significant over-pull despite the well-known sticking conditions in this section of the reservoir.

The new fluid mapping-while-drilling technology has been field-tested in the GOM, Africa, the North Sea and Malaysia. In all cases, subsequent laboratory tests of field samples confirmed the accuracy of the real-time fluid mapping results, providing assurance that laboratory sampling can, in many cases, be eliminated.

石油圈

石油圈