石器时代的结束,并不是因为石头没有了,而是技术迭代的结果。

来自 | E&P

编译 | 张毅

总有人表示,油价这么低,石油业该怎么办?但纵观石油发展史,低油价似乎并不是石油业真正的“催命符”。

当然,油价下跌确实让全行业苦不堪言,但单纯地把低油价认为是石油行业衰落的标志是不妥的。相反,正是油价下跌才刺激了石油消费的增长,并使石油具备了更强的竞争优势。

BP 2017年度能源统计报告显示,迄今为止,石油仍然是当今世界第一大能源。与天然气、煤炭、核电等能源相比,当前人类主要依赖的能源仍然是以石油为代表的化石能源。且过去一年内,世界石油消费量非但没有降低,反而呈持续增长之态。专家预测,未来数十年内,石油仍将是主要能源。这样的产业,怎可能是夕阳产业?

但在人工智能(AI)飞速发展的今天,即使石油业短期内不会受到威胁,石油人也仍需居安思危,掌握职业技能转型的主动权。随着技术的不断发展,是有人将面临的最大挑战也许不是行业前景问题,而是技术更心所带来的威胁。改变方有未来,get新技能才有可能不被时代抛弃。

电潜泵系统用于稳定、抑制段塞流

HEAL电潜泵系统是一种根据井下流体状态而调节的人工举升技术

众所周知,高气水比大深度水平井往往会遭遇气体干扰过大的困扰,电潜泵强大的泵送能力使得人工举升系统能够用于高产深井。然而,对于电潜泵而言,气体干扰经常会导致电机过热,进而引起过多的停机或过早的老化。

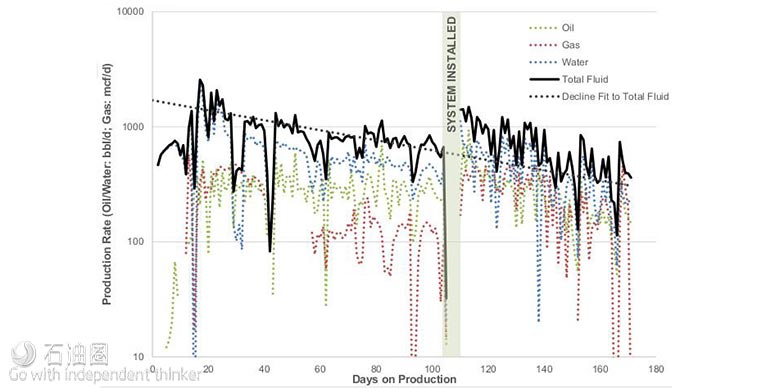

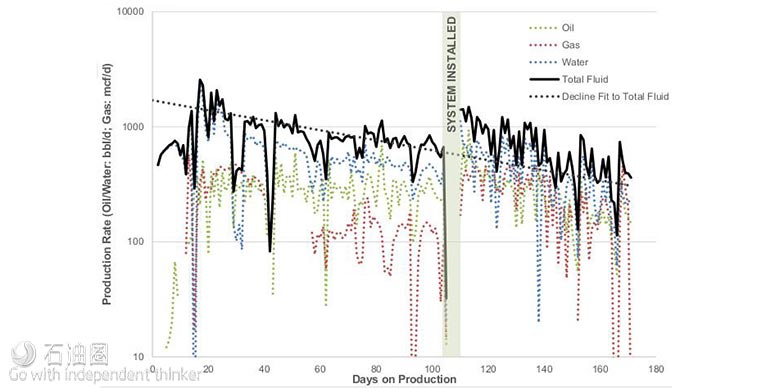

HEAL系统水平增强人工举升(或HEAL电潜泵系统),基于井下流体工况,设计用于平稳并抑制段塞流,从而实现更佳的电潜泵性能。

HEAL电潜泵系统配有密封机罩。一台漩涡分离器将气体泄放至环空,同时将液体引入密封电潜泵机罩底部;液体流经电机起到冷却作用,然后流进吸入口。电潜泵的另外一个挑战在于如何维持临界速度与相应的泵效。为了解决临界速度的问题,HEAL系统在密封电潜泵机罩与套管之间设计了环空区域,用于实现预期气体流速,而不进入临界速度区间。HEAL电潜泵系统采用小孔径设计,来应对更具挑战的工况,在小直径套管内形成段塞流抑制的同时,实现较低的泵入口压力,这样就带来了更高的产量与更低的作业成本。

支撑剂为油井增产

Hexion公司的OilPlus高级支撑剂在超过1000口井上进行了现场验证,在北美主要产油盆地共泵入超过10亿磅。通过增加支撑剂充填层油气的相对渗透率,OilPlus支撑剂可更高的初始压力、更大的累计产量、更低的油当量成本以及更可观的投资回报。最近的生产数据研究证明,OilPlus支撑剂的性能已经超过了传统的树脂覆膜支撑剂。在应用OilPlus支撑剂的多个地区中,二叠纪盆地与巴肯页岩的产量均提升了24%,鹰溪页岩产量提升28%。以上每个案例的工况相近,且都采用了相似的压裂设计。

具有高破坏率的双火炬燃烧系统

Kimark公司的双火炬系统,破坏率高达98%,可用于双流放空的挥发性有机物控制,特别是在必须考虑蒸汽的富油页岩应用中,效果尤为明显。高压和低压破坏在一体化火炬塔中同时发生,其进口压力区间为0~30,气体流量分别达到70.7Mcm/d和141.5Mcm/d。低压气流为风送式,配有一台进口范围在0oz~16oz之间的变速鼓风机。

双火炬系统高级数据录取功能搭配自载计算机,可采集关键数据,满足Quad O以及Oa报告与记录追踪的合规要求。双火炬系统满足NSPS60.18中的标准,包括长明灯、火炬头流速、最低热值、无烟燃烧、自带Modbus通信以及与SCADA系统连接的能力。另外,该系统还配有触屏,可就地控制,还可在紧急情况下切断来气,确保无泄漏作业。双火炬系统装有高液位切断装置、持续火焰探测、入口阻火器以及入口气流切断阀。

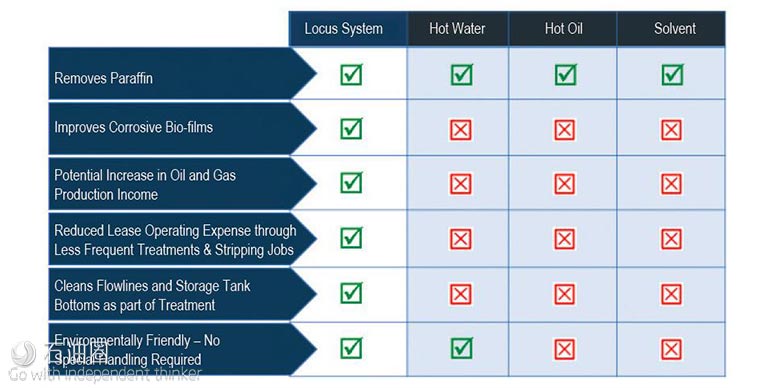

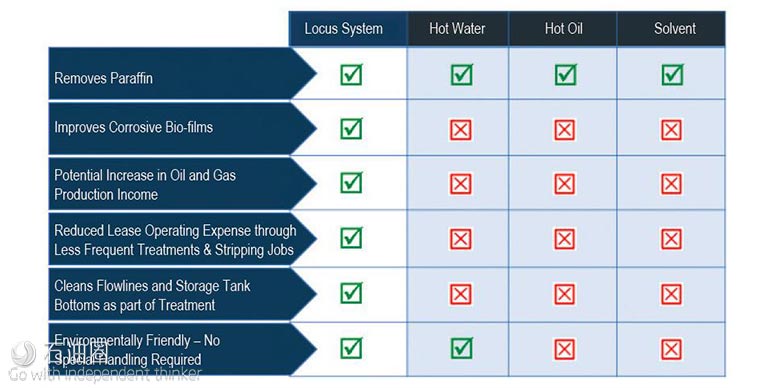

新型控制处理方案能够有效清蜡

Locus生物能源解决方案的微生物技术将鲜活且密集的微生物种群输送至问题位置

所有的常规油田作业公司都需要应对油气井结蜡问题。传统的防蜡处理也许可以暂时清蜡,但必须不断重复处理。传统热油工艺和热水处理,长时间将蜡、苯、甲苯、乙苯、二甲苯等剧毒溶剂推进产层,对产层伤害极大。

Locus生物能源解决方案公司已经开发出一项具有专利权的微生物技术,能够将鲜活且密集的微生物种群输送至问题位置。该处理方法已经在现场成功应用,被证实能够清除油管内以及相连地层岩石的结蜡。此外,微生物处理还能作为增产技术用于解除石蜡、沥青质、树脂以及结垢等在井眼附近意外析出造成的产层伤害。类似的微生物处理还能够快速软化污泥堆积的容器底部,解决有效容量降低的问题。

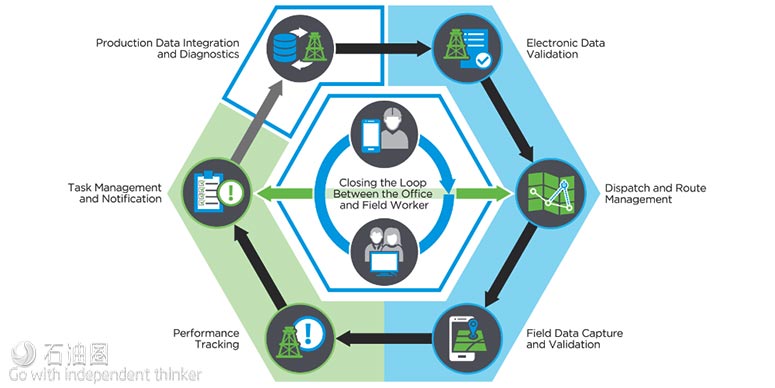

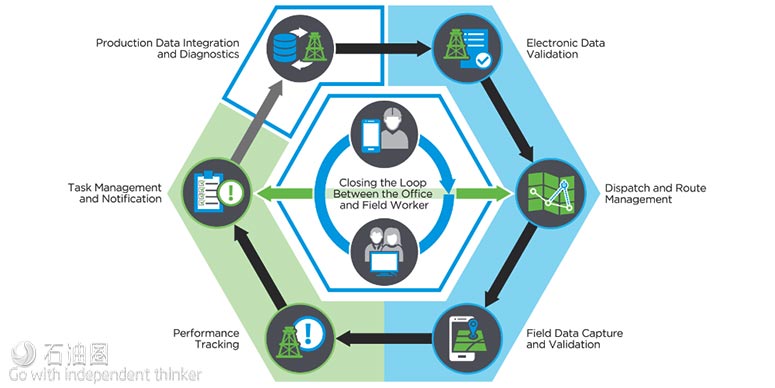

没有出众的监测,就无法实现出众的泵送

P2 Merrick提升移动性能与作业智能性

针对井数多、地理位置分散、重型设备维护成本高等问题,大部分作业者越来越多地依赖技术来解决。而在作业过程中,决策与执行仍然需要人为干预才能实现,这就导致了自动化与数字油田技术的快速发展。海量数据通过技术实现混合,让作业者提高对工况的洞察力和深入了解,让决策制定变得更快、更全面。这自然就提升了产量,也带来了更高的经济回报和利润。P2 Merrick是P2公司推出的一款生产数据管理平台,该公司正着力提高其灵活性和操作的智能化,努力让例外管理变得更加真实可用。

P2 Merrick可以做到:

1.通过平板电脑/手机移动应用连接现场与后方办公室;

2.实时监测与资产性能监测;

3.具有报警功能,并在合适的时间将精准的数据通知到相应人员;

4.可视化与诊断工具,识别并解决相应问题。

P2 Merrick可改善采油人数与井数的比例,降低工时和相关成本,减少停产时间。

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

柠檬:186-2292-2332;weiyameng@fonchan.com

二丫:131-3255-0596;zhanglingyu@fonchan.com

For English, Please click here (展开/收缩)

ESP SYSTEM SMOOTHENS, SUPPRESSES SLUG FLOWS

Deep, high gas-rate horizontal wells are known to experience excessive gas interference. The large pumping capacity of the electric submersible pump (ESP) makes it the artificial lift system of choice for deep high-rate wells. In ESPs, however, gas interference frequently overheats the motor, resulting in excessive shutdowns and premature failures. HEAL Systems Horizontal Enhanced Artificial Lift, or HEAL ESP System, is a downhole flow conditioning artificial lift technology designed to smoothen and suppress slug flows and resulting in improved ESP performance. The HEAL ESP System incorporates an encapsulated shroud. A vortex separator discharges gas to the annulus and intakes liquids into the bottom of the encapsulated ESP shroud. Liquids flow past the motor section to provide cooling and then enter the intake section. ESPs can be equally challenged with maintaining critical velocity and corresponding pump efficiency. To address critical velocity, the annular area between the encapsulated ESP shroud and the casing is designed to achieve the expected gas rates without entering the critical velocity region. The HEAL ESP System manages challenges exacerbated by small hole size, allowing the benefits of slug flow suppression to be achieved in small casing sizes while achieving low pump intake pressures. This results in increased production with reduced capex and opex.

PROPPANTS HELP INCREASE WELL PRODUCTION

Hexion’s OilPlus advanced proppants are field-proven in more than 1,000 wells, with 1 billion pounds pumped in major basins throughout North America. By increasing the relative permeability of oil in the proppant pack, OilPlus proppant users can produce better wells. This includes improved IP, higher cumulative production, reduced cost per boe and higher return on investment. Recent production data studies have proven that OilPlus proppants outperform traditional resin-coated proppants. A 24% increase in production was shown in the Permian Basin. A 24% production increase was shown in the Bakken Formation. And a 28% increase in production was shown in the Eagle Ford Formation. Each case study focused on a single operator using similar fracture designs, and a comparable number of wells were used over long periods of time under similar downhole conditions. Upfront investment of about $30,000 for an 11% tail-in of OilPlus proppants was proven to be returned in less than 30 days in the Permian Basin. Based on $53/bbl oil, wells that used an 11% tail-in of OilPlus proppants generated on average $1.1 million more revenue than offset wells during a 12-month period.

DUAL-FLARE COMBUSTION SYSTEM FEATURES HIGH DESTRUCTION RATE

Kimark’s dual-flare system, featuring a 98% destruction rate efficiency, is designed for dual-stream volatile organic compound control, particularly in rich, oily shale plays where vapors must be considered. Destruction occurs at both high-pressure and low-pressure systems in one modular stack. With a 0 to 30 high-pressure inlet range, gas stream flow rates can be achieved between 70.7 Mcm/d (2.5 MMcf/d) and 141.5 Mcm/d (5 MMcf/d). The low-pressure gas stream is air-assisted with a variable speed blower and inlet ranges from 0 oz to 16 oz. The advanced datalogging capabilities of the dual flare with the onboard computer collects vital data necessary for compliance with Quad O and Oa reporting and recordkeeping. The dual flare meets the criteria set forth in NSPS 60.18 to include continuous pilot, flare tip velocity, minimum heating value, smokeless burn with built-in Modbus communications and SCADA-ready operation. It has an intuitive touchscreen interface for local control and operates in a leak-free capacity with its ability to cut off stream flow in emergency situations. The Kimark dual flare is an efficient combustion system with advanced safety features such as high liquid-level kill, constant flame detection, inlet flame arrestors and inlet gas shut-off valves.

CONTROL TREATMENT PROVEN TO REMOVE WAX PARAFFIN

Locus Bio-Energy Solutions’ microbial technology delivers fresh and dense microorganism populations to problem areas.

Operators of conventional wells across the globe battle excess paraffin wax deposition in oil and gas productions. Conventional control treatments might temporarily remove paraffin wax but must be repeated often. Traditional hot oil processes and hot water treatments might damage formations over time by pushing paraffin farther into the formation, and benzene, toluene, ethylbenzene and xylene solvents are extremely toxic. Locus Bio-Energy Solutions LLC has developed a patent-pending microbial technology that delivers fresh and dense microorganism populations to problem areas. This treatment has been successfully applied in the field and is proven to remove paraffin wax deposits in oil well tubulars as well as adjacent formation rock. In addition, microbial treatments can be used in well stimulation to remove formation damage from various unwanted precipitates near the wellbore such as paraffin, asphaltenes and resins, and any scale attached to them. Similar microbial treatments also rapidly soften tank bottoms that have lost capacity from sludge buildup.

PUMPING BY EXCEPTION CANNOT HAPPEN WITHOUT SURVEILLANCE BY EXCEPTION

Leading operators increasingly turn to technology to address the challenges associated with high well counts, geographically dispersed and remote operations, and hefty equipment maintenance and costs. As automation and other digital oilfield initiatives expand, they must be augmented by the reality that operational decisions and execution still require human intervention. The blending of massive amounts of data through technologies provides operators insight and context and drives faster, more informed decision-making. This improves production and drives revenue and profitability. P2 Energy Solutions is surrounding its production data management platform, P2 Merrick, with enhanced mobility and operational intelligence capabilities to make management by exception a reality for customers. P2 Merrick offers ? Connection of the field and back office through tablet/phone-based mobile applications; ? Real-time surveillance and monitoring of asset performance; ? The ability to alert and notify the right people at the right time with the right data; and ? Visualization and diagnostic tools to support issue identification and resolution. The platform also is designed to improve pumper-towell ratios, reduce man hours and associated costs, and reduce downtime and deferments.

未经允许,不得转载本站任何文章:

石油圈

石油圈