石器时代的结束,并不是因为石头没有了,而是技术迭代的结果。

来自 | E&P

编译 | 张毅

从技术上来讲,除了量子物理算是个意外,其他没有什么是人不能预测的。但在两年前,当分析人士宣称,页岩油气行业将无法在油价低于60刀的状况下维持生计时,却很少有“算命大师”能看到这个行业的前景究竟如何,也就更少有人能预测到如今页岩油气生产的爆发式生长了。

事实上,有很多指标能精准地判断出石油市场会在何时陷入谷底。大部分数据显示,油气市场在2016年1月触底,当时西德克萨斯的半成品油价格跌至$29/bbl;而到5月底,美国的工作钻机数量就已经降至仅剩404台。而时隔两年以后,行业内却出现了戏剧般的爆发,美国已成为净石油生产国,钻机数量现已恢复至2015年的水平。

在这背后,“技术”的戏份可以说是最多的。

防砂系统能够在高流速下保持效率

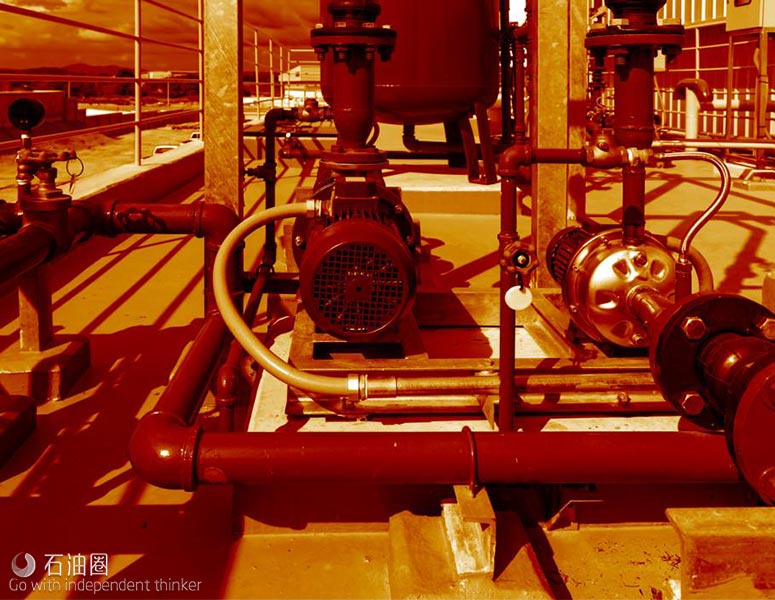

ENERGES出砂管理服务将传统技术与新型技术相结合,可提供不同需求的除砂选择。ENERGES采用双旋风除砂分离器,该分离器内设二级固相分离装置,能够使更多的细砂 “脱落”,同时也高效解决了翻塔的问题,也就确保了下游设备的无砂。ENERGES在用户现场进行了多个测试,评估出砂管理系统的有效性,两个双旋风除砂分离器都用于处理100目的返砂。其中,第二个除砂分离器下游安装的声波监测传感器记录到,有10%~25%的砂翻塔进入下游流程。

在安装除砂过滤器后,过滤器下游检测出的砂量为0。通过检查生产分离器,该数据得到了确认。除了除砂之外,ENERGES还可在除砂率保持在100%的前提下,使用更大尺寸的油嘴。这种改变说明,该过滤器能够在高流速下维持较高的除砂效率。上述技术可保护生产设备免受出砂损坏,同时也可减少频繁关井的问题,保障连续生产。

软件通过实时数据提升压缩机性能

Flogistix LP公司是一家压缩机制造商,同时也为陆上油气作业提供油井优化服务。该公司推出Flux系统,可为压缩机单元提供实时数据,提高用户的设备运行透明度。除此之外,Flux系统还可识别长期趋势,克服业内最大的生产挑战—停产。通过实时遥测、运行参数和检修记录证明,Flogistix公司凭借Flux系统可保证设备有效运行时间长达98%。系统捕获压缩机的工况变化,并将这些变化体现在时间轴上,与其他关键传感器数据进行对比,旨在为用户提供整体画面和更加深入的信息。Flux系统的实时数据采集和长期趋势预测的能力,使其成为了优化生产的有效工具。

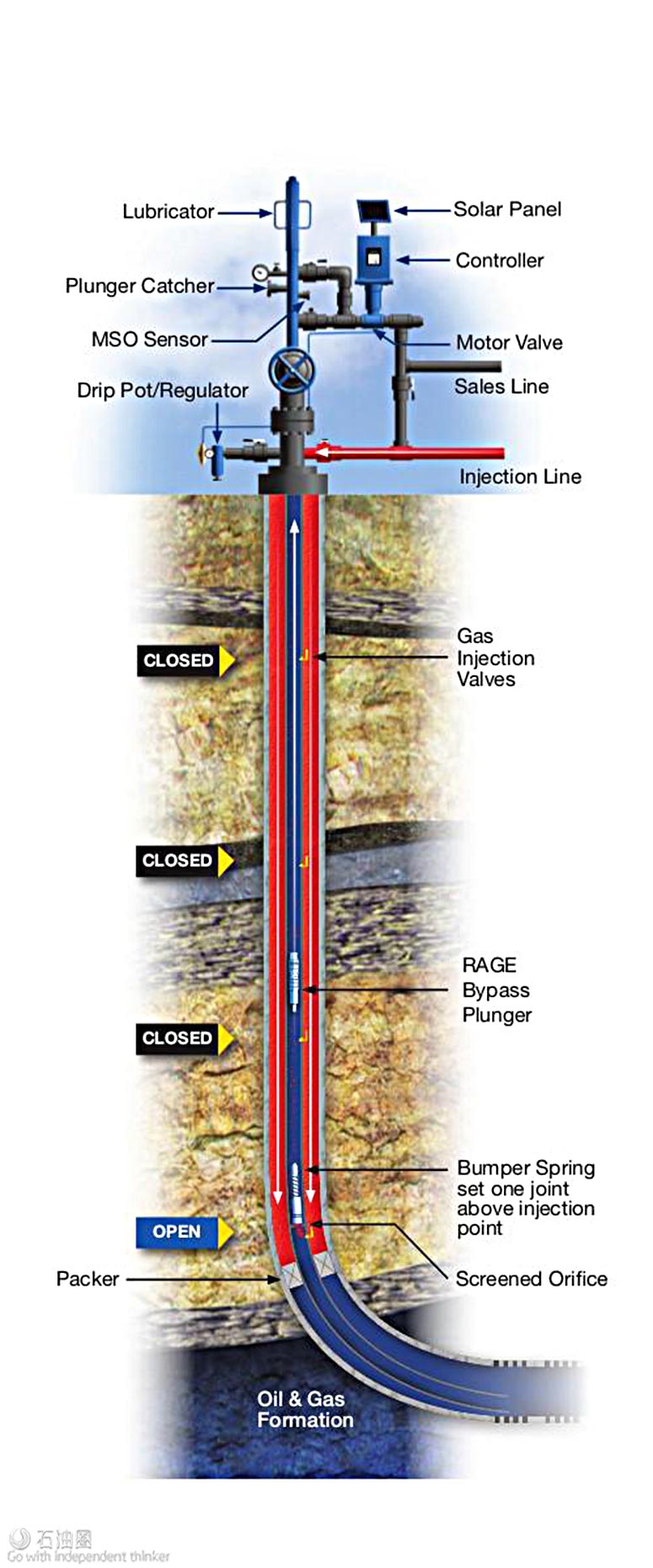

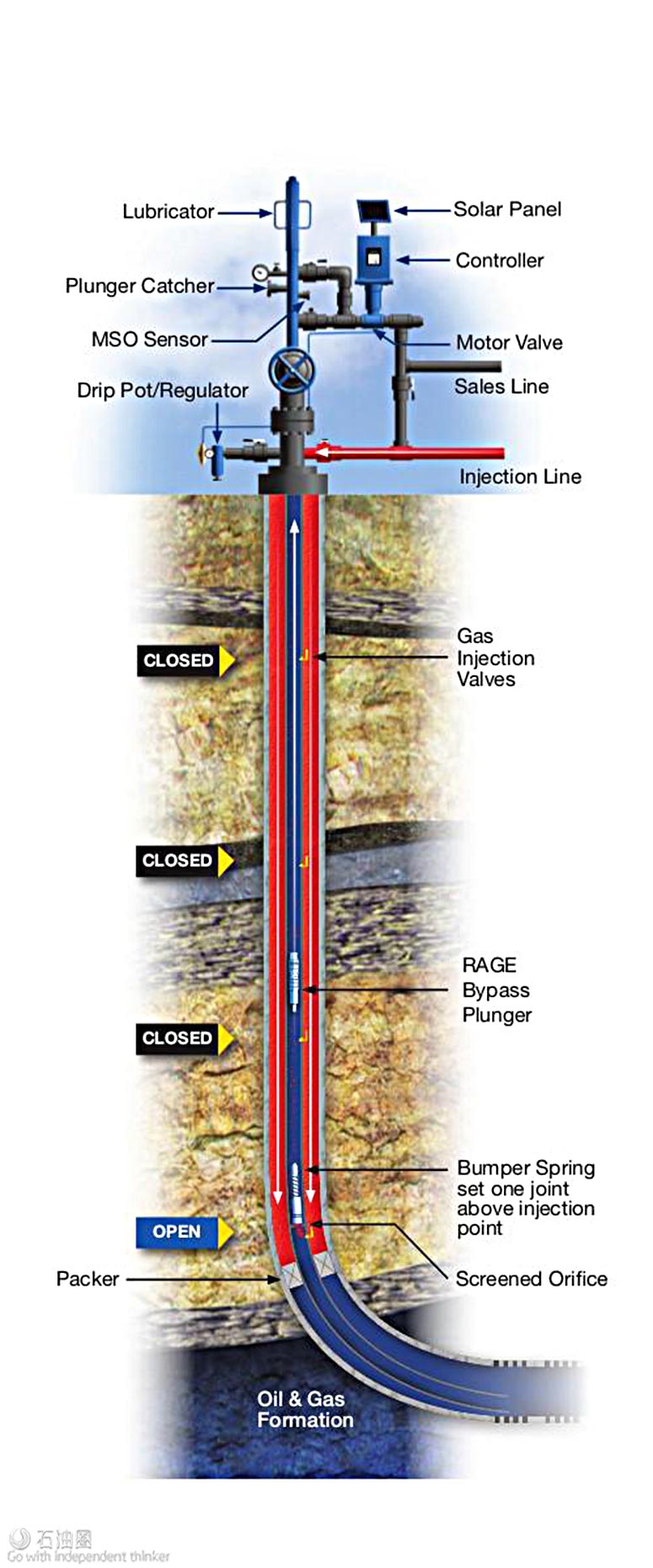

柱塞举升系统用于非常规油气井增产

Flowco公司近期推出了自动化柱塞气举系统,该系统将现有人工举升技术、高级自动化软件运算法则和监测技术相结合,目前已在全球范围内的多口水平非常规油气井实现了降本增效。值得一提的是,融合气举和柱塞举升系统省去了成本高昂的修井作业,在油井和气井的合采应用上都能实现长期利益,而北美运营商正品尝着这块美味蛋糕。柱塞协助气举系统,再搭配自动化应用,目前已经达到了降本的效果,同时也延长了水平非常规油气井的生产周期。

上述举升系统改善了页岩井产量快速衰减的问题,也让作业者得以应对高气水比和高出砂/固相的井,效果显著优于其他举升设备。

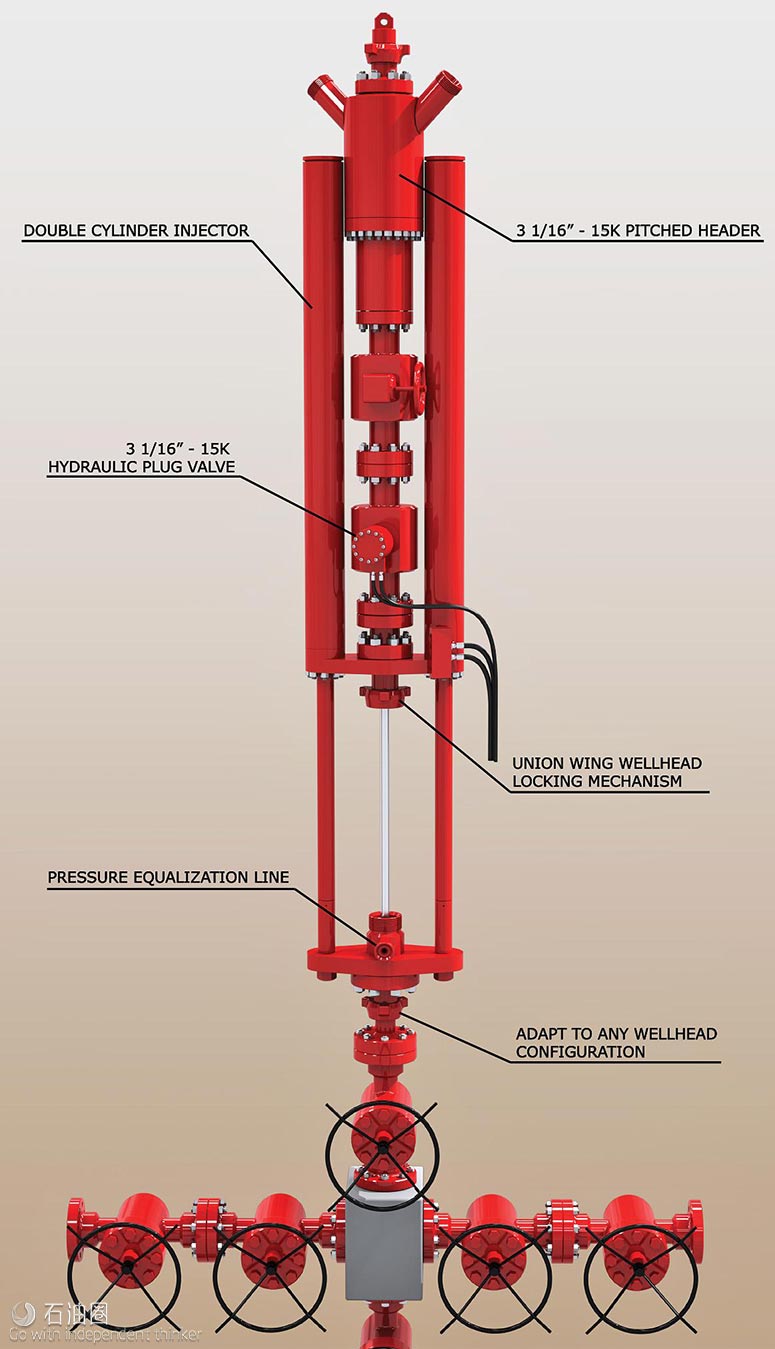

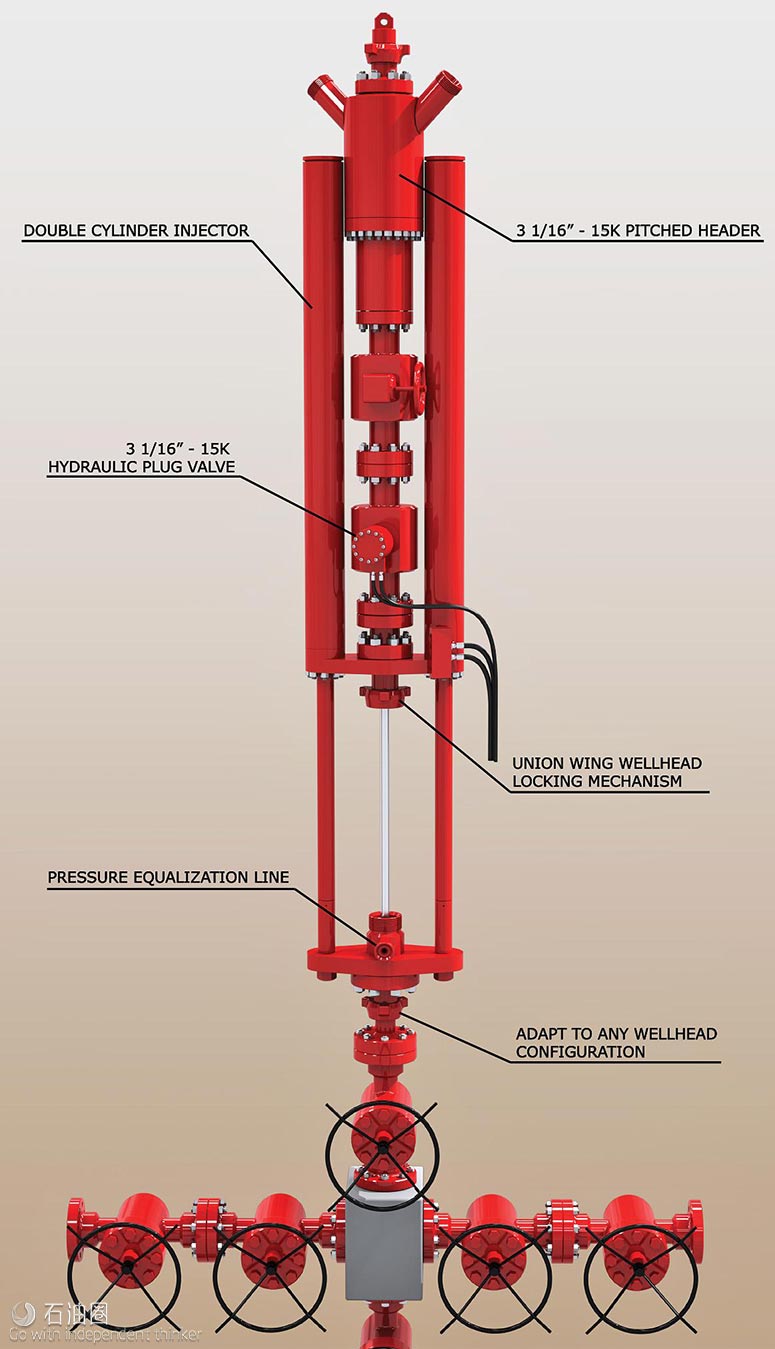

新型隔离工具为高压工况设备提供保护

现代水平钻井和多级压裂,给油气设备带来了前所未有的严苛工况。在此类完井作业中,地面井口设备需要得到有效保护,来对抗高压、高流量工况。

Greene能源集团推荐使用隔离工具,保护井口设备免受高压和粗糙原料的冲击,同时也能保护作业人员免受意外压力泄放造成的伤害。Greene公司的Guardian井口保护工具可协助作业人员通过现有井口直接进行压裂作业,免去了压井作业,同时也降低了除砂与冲蚀的概率。

现有三种的工具Tree Saver、Casing Saver、Stage分别用于油管、套管与井口的封隔,都是利用液压缸/液压单螺杆将工具的主心轴通过井口插入实现的封。三者的平均安装或拆除时间为30分钟,同时井口保护技术的使用能够免除传统租用压裂井口成本高昂的修复工作。

新型服务系统用于识别管线损坏

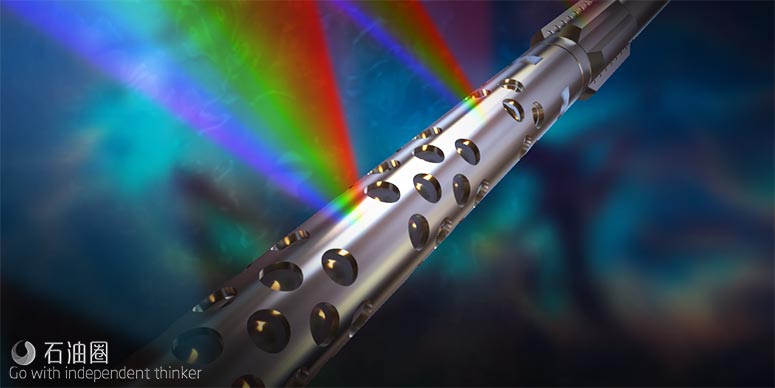

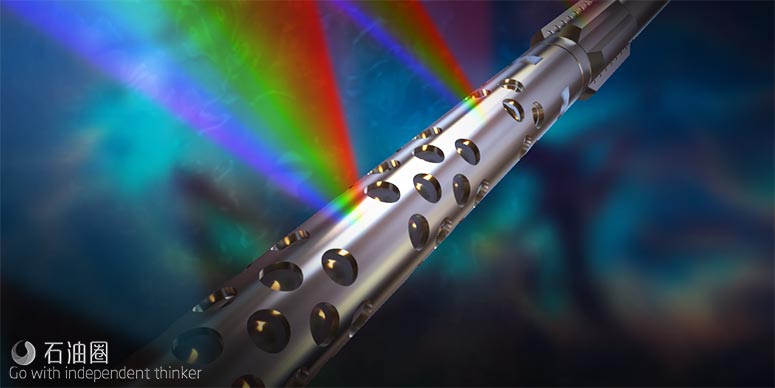

哈里伯顿推出的声波测量(ACX)和电磁管线测量(EPX V)服务,可协助作业者快速识别泄漏位置,并描述出需要修补的管线破损程度。

流体成像工具ACX能够将管线后部流动进行定位并成像,主要用于流动保障,油气井完整性与井漏识别。该工具能够映射包括环空之间的井眼附近流体的流动,并贯穿于整个完井作业过程。

井漏成本昂贵,针对这一问题,主要需进行漏点定位和漏点修复两个环节。对于锁定泄漏位置环节,有常用的几个操作方法,但过程往往耗时很长,且效果差强人意。当存在腐蚀问题时,EPX V管线检测工具可利用精确高频HD技术,对井眼内1~5个同心管柱的金属损失进行量化。该工具只需单次下入,就可协助用户对整口井进行检测,并评价管线情况。EPX V通过向周围管线引入高清频率电磁能,可在没有井眼流体的影响下,通过同心管柱进行扩散;随后信号返回给工具,最终生成反映每根管柱金属损失的有效信息。

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

柠檬:186-2292-2332;weiyameng@fonchan.com

二丫:131-3255-0596;zhanglingyu@fonchan.com

For English, Please click here (展开/收缩)

SAND MANAGEMENT SYSTEM HANDLES HIGH FLOW RATES, MAINTAINS EFFICIENCIES

ENERGES Sand Management uses traditional and emerging technologies to provide a full range of de-sanding options. ENERGES uses dual cyclonic sand separators with engineered inserts for second-stage solids separation to create additional fine sand “fall out,” and the sand filter effectively eliminates the carryover to deliver solids-free production. Several tests were conducted on customer sites to measure the effectiveness of the sand management system. Two dual-cyclonic sand separators were used to combat the 100-mesh sand returns. Acoustic monitoring sensors downstream of the second sand separator were registering that 10% to 25% of entering sand was still carrying over. After installation of the sand filter, sand production downstream of the filter registered zero and was confirmed by checking the production separator. In addition to the successful removal of fine sands, choke sizes were increased while maintaining 100% sand removal. This ramp-up in production shows the filter’s ability to handle high flow rates while maintaining de-sanding efficiency. These technologies mitigate production equipment damage from sand and reduce frequent well shut-ins for maintenance, keeping production online.

SOFTWARE ENHANCES WELL COMPRESSION WITH REAL-TIME DATA

Flogistix LP, a gas compressor manufacturer and well optimization service provider to the domestic onshore oil and gas industry, has released its newest software, Flux. Flux provides real-time insight into compressor unit performance and gives companies enhanced transparency. The system also offers the ability to identify longterm trends, ultimately reducing one of the industry’s main production challenges: downtime. With Flux, Flogistix guarantees a run time of 98%, proven through real-time telemetry, run-time statistics and maintenance history. This is accomplished by capturing changes in the state of a compressor and representing these events on a time line with other vital sensor data, providing context and insight to the user. The ability of Flux to capture real-time data and long-term trending makes it a tool for optimization.

PLUNGER LIFT SYSTEM IMPROVES PRODUCTION FOR UNCONVENTIONAL WELLS

Flowco Production Solutions has recently released its plunger lift-assisted gas lift with automation. This new application of existing artificial lift techniques along with advanced automation software algorithms and monitoring has helped reduce operating costs and improve the production of horizontal unconventional oil and gas wells throughout the world. Specifically, North American E&P operators are experiencing huge benefits of commingling gas lift and plunger lift without the high workover costs of any select pump apparatus—considering that gas-lift and plunger lift systems are the only two artificial lift systems that marry well together with long-term benefits in both oil and gas wells. The application of plunger lift-assisted gas lift coupled with automation has allowed the industry to reduce operating costs and extend the life of rapidly declining horizontal unconventional oil and gas wells. This new artificial lift has improved the way a gas-lift installation operates in the life cycle of a rapidly declining shale well. It also allows the operator to maintain the ability to handle high gas-liquid ratios and sand/solids from the well with no problems, unlike other forms of artificial lift. The system is designed to prolong the need for artificial lift conversion to positive displacement pump and reduce the operator’s monthly well costs by optimizing compression. Horizontal wells are not an issue for plunger lift or gas-lift systems as experienced with positive displacement pumps. The deep lift opportunity of Flowco’s applications helps increase profit margins on product sold by reducing operating costs, reducing workover costs for repair and maintenance and increasing production.

ISOLATION TOOLS RECOMMENDED FOR PROTECTING EQUIPMENT AMID HIGH PRESSURE

Never before has oil and gas equipment been subject to such abrasive conditions as found in modern horizontal drilling and multistage fracturing jobs. During these challenging completion operations, surface wellhead equipment needs to be efficiently protected from high-pressure, high-volume conditions. Greene’s Energy Group recommends the application of isolation tools to protect the wellhead equipment from high pressures and abrasive materials as well as protecting personnel operating at surface from unplanned pressure events. Greene’s Guardian Wellhead Protection tools allow operators to fracture directly through the existing wellheads, eliminating the need to kill the well and reducing the possibility of sand and erosion, which causes valves to fail during the operation. There are three different versions of the tool system that seal off in tubing, casing or the wellhead. The Tree Savers use hydraulic cylinders to insert the main mandrel of the tool through the tree and wellhead bore and sealoff in the tubing inside diameter (ID). The Casing Savers use hydraulic cylinders to insert the main mandrel through the tree, wellhead bore and seal-off in the casing ID. The Stage Tools use a hydraulic single screw to insert the main mandrel through the tree and seal-off in the wellhead bore. The average installation or removal time is 30 minutes, and the use of wellhead protection technology can eliminate costly repairs to conventional rental fracturing trees.

SERVICE SYSTEMS HELP FIND PIPE DAMAGES, OFFER EFFICIENT SOLUTIONS

Halliburton provides time-saving analysis through new technologies. Accurate diagnostics are critical to help keep projects on budget and on time. The Acoustic Conformance Xaminer (ACX) and Electromagnetic Pipe XaminerV (EPX V) services help operators quickly find a leak’s location and describe the extent of the damaged pipe that needs fixing. Halliburton created the flow imaging tool ACX, which locates and images flows behind pipe(s) and is primarily used for flow assurance, well integrity and well leaks. The tool can map fluid flow around the wellbore, including in between annuli and throughout the completion. Well leaks are very costly to production returns, including the cost of locating and repairing them. There are several operational techniques for narrowing down a leak’s location. However, these can be time-consuming and might not fully explain what is occurring. When corrosion is a problem, the EPX V pipe inspection tool quantifies metal loss in one to five concentric strings of pipe in a wellbore using accurate high-definition (HD) frequency technology. The tool helps customers examine the whole well in one trip and assess pipe condition. The EPX V operates by inducing HD frequency electromagnetic energy into the surrounding pipe, which propagates through the concentric well strings with no wellbore fluid influences. The interaction with the metal of the pipe returns signals to the tool, yielding information about the state of metal loss in each pipe.

未经允许,不得转载本站任何文章:

石油圈

石油圈