是什么让企业在动荡时代站稳脚跟?墨守成规总归不是妙计。

来自 | E&P

编译 | 二丫 影子

为何美国页岩油的成本越来越低?这是因为美国石油企业一直致力于页岩油开采技术的创新,且将其技术应用于含油砂岩的开采和炼化中。在石油与天然气的钻井、开采及炼化过程中,不断发展和进步的高精端技术为“石油科技提供了超级能量”。

在技术的新时代,谁有创新和适应能力,谁就能够控制和影响市场。美国、沙特阿拉伯和俄罗斯是世界上效率最高、规模最大的石油市场,他们都将实验和使用水平井钻井、压裂技术作为他们未来技术的发展趋势,而在这三个国家中,美国的技术领先一筹。

管式处理系统有助消除腐蚀和应力开裂

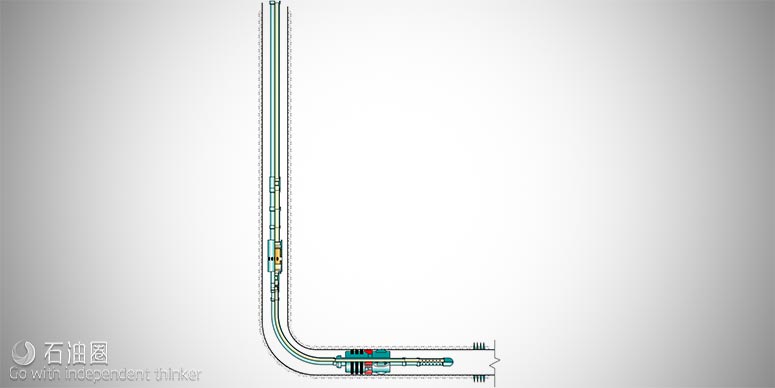

除了石油天然气上游作业产生的H2S之外,页岩地区提取烃的人为过程也会释放出大量硫化氢。因此,这些地区往往需要使用耐腐蚀合金(CRAs)来缓解酸性气体带来的损害。然而包括CRAs在内的大多数管式处理设备常见磨具等工具,都会在管道上留下痕迹,在酸性井中,这就会增加井下管道对腐蚀性物质和硫化物应力开裂的敏感性。K公司目前发布了其新一代27-1/2英寸S技术,作为上述问题的解决方案。

这款无痕处理系统具有旋转式震动台,能够连接27-1/2英寸甚至更小的旋转,是陆上钻机的理想选择。该系统配有改进过的滚轮和纵摆稳定性,250吨的额定冲击台可以在整个联轴器的承载面上提供对关注的最佳支撑,为陆上作业提供足够的承载能力。

新型钢丝系统保护人工举升设备免受压裂作业冲击

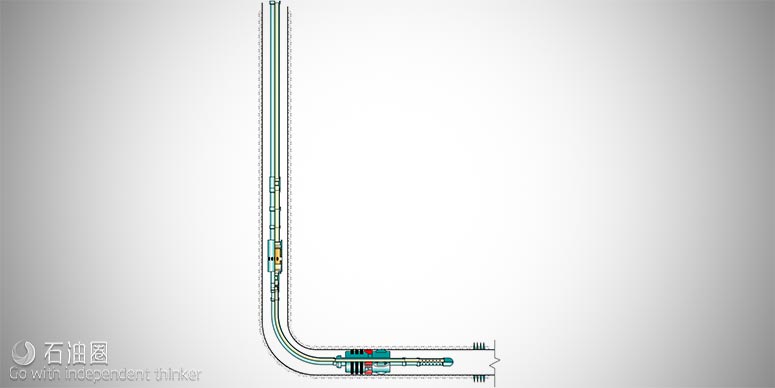

在页岩开发活跃的地区,压裂作业带来的冲击和损害日趋严重,油气开发商在此方面的忧虑也逐渐增加。压裂冲击可能来源于探边井的压裂作业,在生产井附近的压裂作业也会造成一定影响。一般来说,压裂冲击会导致生产井井筒充满压裂砂,降低生产效率,其对于人工举升系统的影响更为严重,甚至会引起地面设备压力过高,诱发井控问题。HEAL Systems公司的Horizontal Enhanced人工举升钢丝系统(简称HEAL Slickline)能够提供一种简单、高效、经济的人工举升设备压裂冲击保护方式,并且其安装也非常简便。

HEAL Slickline配置了可回收分离器,该设备可作为防止井筒受压裂冲击影响的深度保障。在探边井压裂作业前,通过使用钢丝将HEAL系统的分离器下入井筒,同时完成标准规格堵塞器的安装。在探边井压裂作业完成后,回收堵塞器,井筒即可投入生产。如果不适用HEAL Slickline系统,作业人员则必须提出整套人工举升设备和生产管线才能完成堵塞器的安装。显而易见,HEAL Slickline系统的使用避免了复杂的作业,相对于常规作业,显著降低了作业时间和成本。

新型支撑剂储存罐提高作业现场安全性和作业效率

提高页岩油藏采收率取决于多方面因素,其中是否能够安全、持续、有效的提供大量压裂用支撑剂就是关键的一点。在多数现场作业中,压裂作业需要在短时间(几天)内使用500卡车当量的支撑剂,显而易见,由此而引发的地面作业、交通将非常混乱。若采用常规的卡车运输,装卸过程就需要一个小时,同时伴随着交通混乱、噪音、粉尘等危害。为此,SandBox Logistics采用该公司特有的专利技术,开发了一款能够解决作业现场交通堵塞、更安全、更清洁的支撑剂物流方案。装有支撑剂的特殊储罐在5分钟内即可完成装卸,同时不会产生噪音、粉尘问题。该公司副总裁Zach Carusona说:“我们在支撑剂存储站或是矿山将储罐填满,之后一次性将40~60个储罐运抵井场,通过传送带将支撑剂送入搅拌器。”Producers Service公司的执行副总裁Dan Mullins表示:“SandBox Logistics公司的新型支撑剂运输方案非常安全高效,同时能够节约成本,通过使用SandBox,支撑剂使用的唯一瓶颈也消除了。我们还极大的降低了员工暴露在粉尘中的风险,提高了整体HSE水平。”

新型燃气轮机燃料灵活性更高,工作寿命更长

Vericor公司的TF50F和TF40F燃气轮机专为油田及其他苛刻工作条件设计,由于设计紧凑,TF50F和TF40F设备非常轻便,易于运输,发电载荷分别为5000hp和2000hp。新型燃气轮机性能强大,支持包括水力压裂、钻井、移动发电设备、气体压缩、油气富集等作业的进行。在降低设备尺寸和重量的前提下,新型燃气轮机的燃料利用范围更广,包括天然气和液体燃料,在必要的时候可在两种燃料间灵活切换。与目前行业常用的柴油发动机相比,Vericor的燃气轮机更加轻便,体积更小,在降低液体燃料运输&储存费用方面竞争优势明显。此外,新型系统的抗干扰性能也得到了显著提升,尾气排放量降低,对环境污染更小,噪音和碳排放影响更低。例如,在水力压裂作业中,使用Vericor的燃气轮机可以提供常规发电机双倍的动力支持,在提供相同动力的同时减少现场工作人员数量,降低相应成本。Vericor的燃气轮机还可以使用油田的火炬气为燃料,将其转换为电能或热能,加以利用。目前,新型燃气轮机的累计使用时间已超过100000小时,其中一台燃气轮机在累计工作超过30000小时后才进行了一次大修,与其他柴油发电机相比性能更稳定,停机频率更低,维护成本更低。

随着科技在世界经济领域扮演着越来越重要的角色,我们期盼传统市场迎来“第三次工业革命”。由美国石油和天然气行业发展的新技术,可能很快主宰全球的油气行业,因为这些新技术和新工艺引领其他国家的石油公司进入全球市场。下一个主宰石油未来的未必是谁拥有多么丰富的资源,而是通过适应不断变化的油气市场来发展技术、实现创新,从而在行业进行投资和竞争的国家和公司。

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

柠檬:186-2292-2332;weiyameng@fonchan.com

二丫:131-3255-0596;zhanglingyu@fonchan.com

For English, Please click here (展开/收缩)

TUBULAR HANDLING SYSTEM HELPS ELIMINATE CORROSION AND STRESS CRACKING

In addition to the natural generation of H2S through oil and gas upstream production, the anthropogenic processes (e.g., hydraulic fracturing) used to extract hydrocarbons from shale formations release substantial volumes of H2S during production. The vast presence of this toxic gas in regions particularly fraught with sour gas reserves jeopardizes well integrity via tubular corrosion. As a result, corrosion-resistant alloys (CRAs) often are required in such regions to mitigate sour gas-induced damages. Gripping inserts or dies common to most types of tubular handling equipment, however, leave impressions on pipe—including CRAs—that, in sour wells, increase downhole tubular susceptibility to corrosion and sulfide stress cracking. K’s has released its next-generation 27?-in. Collar Load Support technology as a solution. The fully nonmarking handling system features an above-the-rotary shock table with the ability to interface rotaries of 27?-in. or smaller, which is ideal for land rigs. With improved roll and pitch stability, the 250-ton-rated shock table provides optimum support of the tubular string over the entire coupling load-face as well as ample load capacity for land operations.

ARTIFICIAL LIFT SLICKLINE SYSTEM PROTECTS AGAINST FRACTURE HITS

For oil and gas producers in active shale fields, fracture hits are a growing concern. A fracture hit occurs when an offset well is fractured and the fracture communicates with another producing wellbore. A fracture hit can cause the well to fill with fracture sand, resulting in productivity losses. The impact can result in severe damage to the artificial lift system and possibly a well control event with excessive pressures at surface. HEAL Systems’ Horizontal Enhanced Artificial Lift, or HEAL Slickline System, offers economical fracture hit protection with greater access to the wellbore and easy installation.

The HEAL Slickline System incorporates a retrievable separator prong that is replaced with a deep barrier to protect the wellbore from the consequences of a fracture hit. Before the offset well is fractured, a slickline unit pulls the HEAL separator prong and installs a standard profile blanking plug. After offset well fracture operations are complete, the blanking plug is removed and the well is put back on production. Without the System, operators often pull the full artificial lift system and production string to run a deep bridge plug. With the HEAL Slickline System all operations are performed with the production tubing left in place, significantly reducing cost over the conventional solution.

NEW PROPPANT CONTAINERS ENHANCE SITE SAFETY AND EFFICIENCIES

Getting the most out of shale wells relies on many factors, including the ability to safely, consistently and efficiently receive high volumes of proppant. At many well sites 500 truckloads of proppant are required to arrive within days, gridlocking surface operations. Unloading traditional pneumatic trucks can take up to an hour each, and there are additional hazards in addition to congestion such as dust and noise. SandBox Logistics has developed patent-protected equipment and processes to mitigate wellsite congestion and ensure a safer, cleaner environment. Specialized containers are unloaded in less than five minutes without the noise and dust concerns of pneumatic trucks. “We fill stackable SandBox containers at transload facilities or regional mines,” said Zach Carusona, SandBox vice president of business development. “We then stage 40 to 60 SandBoxes at the well site, where they are placed onto a conveyor system that delivers the proppant directly into the blender hopper.” Dan Mullins, executive vice president of operations and sales at Producers Service Corp., said SandBox Logistics has generated significant benefits at his well site. “The process is safe and efficient, which translates into cost-savings,” he said. “Using SandBox, we eliminate a main bottleneck in the system. We also greatly reduce the risk of silica dust exposure for our crew, which is foremost in our HSE program.”

GAS TURBINES OFFER FUEL FLEXIBILITY, EXTENDED OPERATING LIFE

Vericor’s TF50F and TF40F gas turbines designed for oilfield and other tough-environment portable applications are compact, powerful (5,000 hp) and light (2,000 lb). The turbines feature hydraulic fracturing capabilities, power for drilling rigs, mobile electric power, gas compression stations and cogeneration for oil and gas processing plants. The turbines also offer reduced weight and size as well as fuel flexibility. The engines can run on natural gas or liquid fuel and switch between the two fuels during operation if needed. In comparison to current diesel engines, Vericor’s gas turbines are lighter and smaller, offering cost savings in logistics and diesel transportation. The systems also minimize disturbances, reduce the environmental impact through less emissions, lower noise and offer a smaller carbon footprint. In the case of hydraulic fracturing such a scenario can represent a doubling of the power of each fracturing unit, leading to additional savings of reduced personnel needed to operate the equipment onsite. Vericor’s gas turbines also could be used with field flared gas, transforming the gas into electrical energy and heat. The engines often exceed 100,000 hours of operation, with a first major overhaul occurring at 30,000 hours, an advantage in terms of downtime and maintenance cost over diesel engines.

未经允许,不得转载本站任何文章:

石油圈

石油圈