是什么让企业在动荡时代站稳脚跟?墨守成规总归不是妙计。

来自 | E&P

编译 | 二丫 影子

油价纠结于50一线,各石油公司不断减产,出现了诸多问题,我们应该以什么样的方式去找到切入点解决这些问题呢?答案是技术创新,只有通过新技术、新工艺的不断发展,才能为我们石油行业注入新的动力。

从2014年末油价开始下跌以来,各国越来越关注石油开采成本,尤其是美国,其石油产量中的50%都来自于页岩层,起初分析师对于页岩油开发成本保本估价为75美元/桶,后来降低至50美元/桶,如今在一些核心区,保本估价已经低至30~35美元/桶。

为何美国页岩油的成本越来越低?这是因为美国石油企业一直致力于页岩油开采技术的创新,且将其技术应用于含油砂岩的开采和炼化中。在石油与天然气的钻井、开采及炼化过程中,不断发展和进步的高精端技术为“石油科技提供了超级能量”。

在线水资源数据库 提高水利用效率

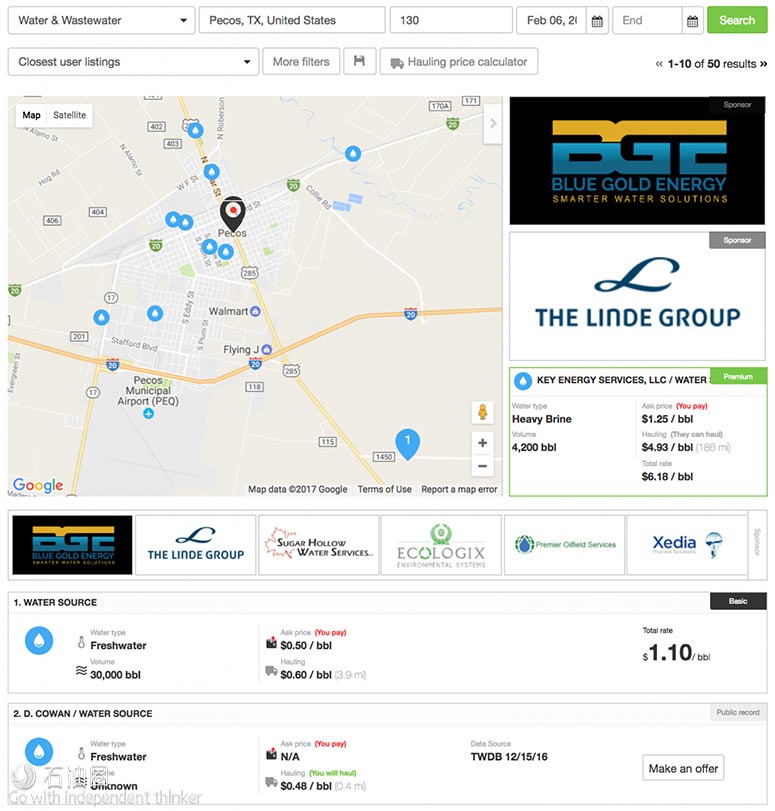

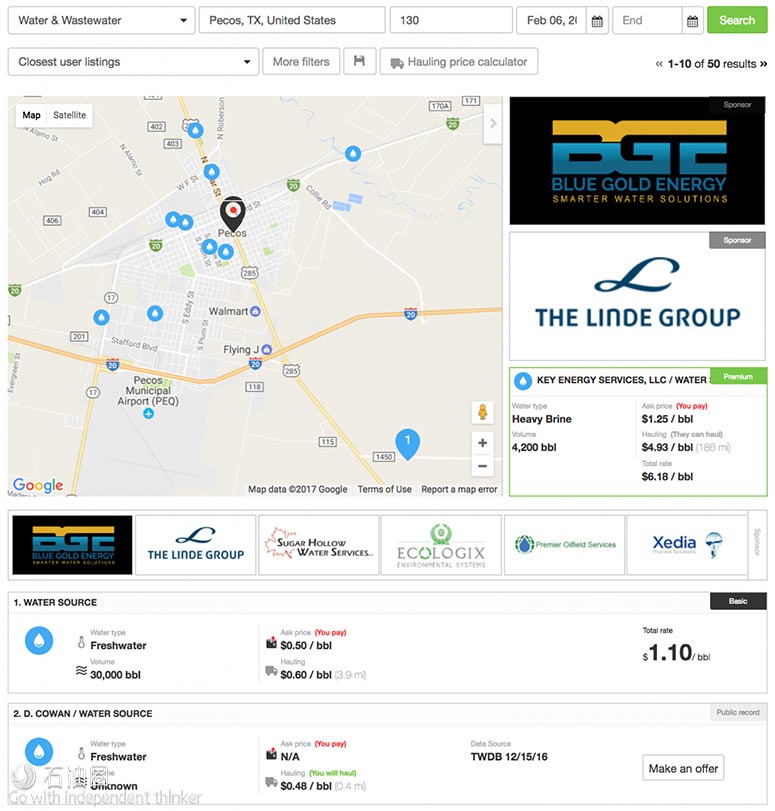

Sourcewater.com是一个涵盖水资源和水处理信息的在线平台,类似于eBay。在过去的五年中,水平井完井用水量已经从100,000 bbl/每级压裂增长到现在的500000bbl/每级压裂,而且增长趋势还在继续,此外,垫块钻井通常在短时间内需要数百万桶的水。从历史数据来看,在与承包商达成一致后,油田作业用水大部分来自于地表。但现在情况发生了变化,油藏富集地区的可用水资源越来越少,钻完井承包合同也逐渐舍弃了用水义务条款。由于垫块钻完井的用水量巨大,水的运输极具挑战,而垫块作业时通常要保证有丰富的水源。由于用水量的迅猛增加,常规水源已经无法满足油气行业作业需求。

Sourcewater.com为开发商提供了一条新的水源获取途径,只需在该网站上匿名提出用水量需求,就会有作业范围内的水源供应商提供水源竞标,其他信息还包括水类型、水质、水源地点、价格、物流成本、水量及可送达日期等。Sourcewater.com的水源反向拍卖能够显著降低开发商的用水成本,还提供了水源信息,甚至还包括非常规水源,包括产出水、回流水、净化水及开发商的额外水源。Sourcewater.com降低了完井中水的管理时间,确保了水的供应,降低了水的物流成本。此外,该系统还帮助开发商计算作业剩余用水,提高基础设施的使用率,增加投资收益。

自动投送系统定位支撑剂短缺

北美页岩气田的井水平段长度、压裂技术和压裂砂体积的增加,直接造成了支撑剂的短缺。数据显示,今年的砂岩需求量将达到6500~8000万吨,而到2018年又将飙升到9000~12000万吨,进而达到历史最高点。

PropX是一家支撑剂输送系统供应商,开发出了一种高效的移动投送系统,已经在过去的几个月之内投送了超过20亿磅支撑剂,并创造了24小时内单次压裂投送930万磅支撑剂的记录。使用PropBease 输送系统,PropX可采用重力进料系统,可消除灰尘,减少压裂砂喷吹噪音,可在常规平板上传送更多压裂砂,能够快速卸载。二氧化硅粉尘测试表明,PropX系统可达到甚至超过2018职业安全和健康管理规定的标准。

全电动压裂车队可节省成本

在如今这个推动高效率、增强页岩地层经济性的时代,环境问题也是无法忽视的关注焦点,水力压裂市场的选择甚少。Evolution Well Services却将整个年度的压裂成本降低了3000万美元,排放量远远低于环保署的第四级标准,泵拖车行程减少67%,噪音水平降低到82dB。以上这些数字,都归功于该公司的多功能压裂车队—有单个天然气燃烧涡轮机提供100%电力的48,000hhp压裂机组。这种功率密度将所有辅助设备的整体占地面积减少了46%,整个车队也更加安全。

柴油&天然气运行燃油机可提高压裂效率

Frac Shack国际公司最近发布了全球第一个用于水力压裂的柴油&天然气自动加油装置。无论是柴油还是天然气,16米(53英尺)的移动式拖车都能让作业人员安全有效地燃烧燃料,并通过现代化生产线和消耗数据来提高他们的分析准确性。

该移动单元有12条天然气管线和12条柴油管线,其中包括自身7900加仑的柴油箱。Frac Shack的双燃料分配单元能够与LNG、CNG和管道气等相兼容。双燃料压裂泵能够每个泵具有平衡、一致和可平衡的压力。因此压裂服务公司和终端用户可以确信,他们可以实现最佳替代率。无需拆卸或减压即可节省时间,quick-connect气体连接可以确保开关泵的快速高效。

柴油和天然气相结合的模式,打破了任何时候都需要燃料卡车的局限性,大大降低了设备成本费用和交通费用。

下期关键词:地面设备

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

柠檬:186-2292-2332;weiyameng@fonchan.com

二丫:131-3255-0596;zhanglingyu@fonchan.com

For English, Please click here (展开/收缩)

ONLINE WATER-SOURCING DATABASE ALLOWS OPERATORS TO FIND, DISPOSE OF WATER

Sourcewater.com is an online platform for water sourcing and disposal—a type of eBay for water. During the past five years, horizontal completions have grown from using 100,000 bbl of water per fracture to 500,000 bbl or more. Pad drilling requires millions of barrels in a short time. Historically, most water came from surface use agreements with drilling parcel owners. But now there is rarely enough water on any one parcel to supply completions. Pads require multiple redundant water sources—a huge planning and logistical challenge for completions. With water consumption setting new records, there is not enough from traditional sources to meet industry needs. Sourcewater.com enables operators to post their upcoming water needs anonymously, then receive competing water source and disposal bids from every landowner, operator and service company within range, including water type, water quality, location, price, logistics cost, volume and dates available. Sourcewater.com’s reverse auction drives down total cost while revealing all possible supplies, even nontraditional sources like produced water and flowback, treated water, and excess operator water. Sourcewater.com reduces completions engineering time managing water, ensures the water supply chain and reduces water and logistics cost. The system also enables operators to market excess water capacity to improve their infrastructure return on investment.

DELIVERY SYSTEM ADDRESSES PROPPANT SHORTAGES

Increasing lateral lengths, stage counts and fracturing sand volume in North American shale plays are creating a shortage of proppants. These factors point to fracturing sand demand of 65 million tons to 80 million tons this year and 90 million tons to 120 million tons in 2018—double historic maximums. Sand production at the mines and sand transportation along the railways will both be tested, but the final pinch point of “last-mile sand logistics” could likely be the determining factor of whether the needed supply reaches the wellhead. PropX, a proppant delivery system provider, has developed an efficient mobile delivery system that has delivered more than 2 billion pounds of proppant during the past six months, including a record 9.3 million pounds delivered by a single fracturing spread in a 24-hr period. Using a gravity feed system to eliminate dust and reduce the noise of fracturing sand blowoff along with the PropBeast conveyor system, PropX allows the hauling of more sand per truckload on conventional flatbeds for fast unloading as well as the ability to prestage proppant on location in areas requiring long hauls over treacherous roads. Silica dust testing indicates that PropX systems meet or beat the expected 2018 Occupational Safety and Health Administration regulations.

FULLY ELECTRIC FRACTURE FLEET COULD LEAD TO COST SAVINGS

In today’s era of pushing for high efficiencies and enhanced economics in shale formations while also being conscious of environmental concerns, little or no options exist in the hydraulic fracturing market. Evolution Well Services provides the ability to reduce overall annualized fracturing costs by up to $30 million per fleet, lower emissions to well below Environmental Protection Agency Tier IV standards, implement a 67% reduction in pump trailer footprint and reduce noise levels to 82 dB. This is accomplished by powering the 48,000- hhp fracture fleet with 100% electricity from a single natural gas-burning turbine. This power density allows overall pad footprint, including all ancillary equipment, to be reduced by 46%. Evolution’s multipatented fleets are also much safer and eliminate the need for “hot fueling.”

DIESEL, NATURAL GAS-OPERATED FUELING UNIT ENHANCES FRACTURING EFFICIENCIES

Frac Shack International Inc. recently released the world’s first combined diesel and natural gas automated fueling unit for hydraulic fracturing operations. The 16-m (53-ft) mobile trailer unit allows operators to safely and efficiently fuel fracture spreads with both diesel and natural gas as well as increase the accuracy of their analysis with modernized line and consumption data. The mobile unit features 12 natural gas lines and 12 diesel lines and includes its own 7,900-gal diesel tank. Frac Shack’s Bi-Fuel Distribution Unit is compatible with LNG, CNG, field gas and pipeline gas. The Bi-Fuel Frac Shack ensures equal, consistent and measurable pressure to each individual pumper, so both fracture service companies and end users can be confident they are achieving the best substitution rate possible. Significant time savings are achieved with no disassembly or depressurizing required. The quick-connect gas connections ensure switching out pumpers is fast and efficient. The combined diesel/natural gas supply reduces costs and traffic on locations by removing the need to have fuel trucks onsite at all times.

未经允许,不得转载本站任何文章:

石油圈

石油圈