是什么让企业在动荡时代站稳脚跟?墨守成规总归不是妙计。

来自 | E&P

编译 | 二丫 影子

本世纪以来,能源方面最大的突破就是致密油和页岩油气的成功开发。页岩油气对全球能源市场具有深远影响,目前美国是开采页岩油气最成功的国家。然而,美国的页岩油气产量在经历了爆炸式增长之后,似乎在低油价面前迷失了方向。

虽然美国的页岩油气产量在持续减少,预计2017年的产量为420万桶/天,但随着技术进步速度的加快和油价回升,美国的页岩产量将在2040年达到1290万桶/天。EIA认为,产量的增长主要得益于油价的回升以及新油田的不断发现。

为了实现可持续发展,石油业需要通过大量的实验、分享良好实践以及新技术和现有技术的应用来实现自我革新。

连续油管系统有效延长润滑增强时间

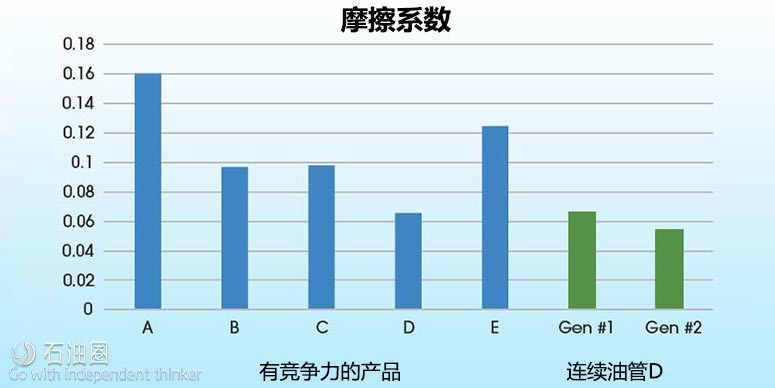

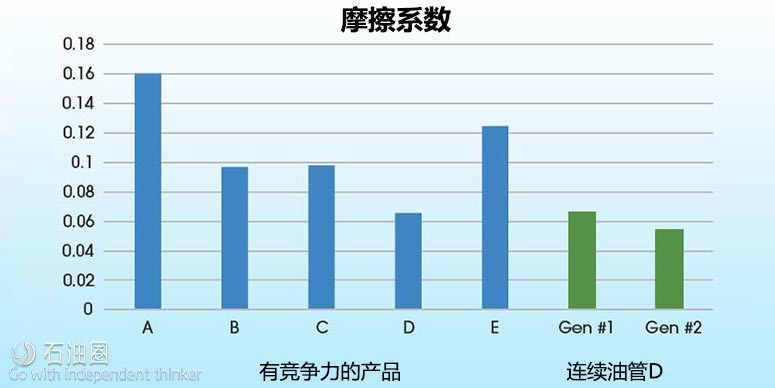

该图显示了Resurre连续油管系统中两个Newpark产品所实现的低摩擦系数

Newpark的Resurre CT系统专为提高连续油管润滑性而设计,特别是针对水平段较长的页岩低产井,效果更佳。工具在水平段时往往需要更好的润滑性,以减少金属之间相互接触产生的摩擦。较长的水平段还需要控制扭矩和牵引力,这直接决定着钻井成本。

Resurre CT系统的润滑剂即可解决CT作业中的上述关键问题。系统中的DireCT可有效减小管道之间的摩擦,可利用Falex Block-on-Ring测试来评估磨损系数和稳态系数。由专有润滑剂所提供的低摩擦系数提高了CT作业效率,让其有增加钻头重量的空间,同时也可减少作业趟数。ResuureCT系统在各种密度下均有效,且抗温能力超过204℃(400℉)。这样一来,无论是运营还是工程方面的收益,都会为用户带来重要价值。

新型工具有效增强页岩干预和增产效率

国民油井华高发布了几款旨在提高页岩干预和增产作业性能效果的工具。CTES酌情监控系统(CBM)和德克萨斯石油工具堆叠监控器是用于油井干预和增产设备的实时监控系统。CBM系统可监测泵、轴承、过滤器和发动机以及液压动力和润滑系统的运行状况。早期识别潜在故障可以提高设备的正常运行时间,并降低维护成本,同时又能确保井场的效率和安全性。QT-1400是新一代超高强度连续油管,根据NOV提供的信息显示,QT-1400具有140磅/平方英寸的最小屈服强度,是市场上最结实的连续油管。因其在高压下存在较大的阻力,QT-1400具有低周疲劳裂纹特性,这是页岩气开采最为理想的选择。

对于具有较长横截面的水平井来说,能承受恶劣井下环境的连续油管在重复压裂和深水作业中至关重要。

分支水平井连接技术增加油藏井筒接触面积

随着页岩油藏开采技术的不断成熟,开发商们对于提高有限油藏采收率、降低开发成本的期望也更加迫切,多分支水平井技术是一种非常有效的增加井密度方案,同时不会对现有地面设施造成巨大影响。斯伦贝谢的RapidTieBack TAML 3/4分支水平井连接技术能够在增产作业中选择性连接、隔离不同分支井,有效提高分支井的增产效率。RapidTieBack TAML具有出色的悬挂能力,在地面设备面积最小的同时最大化水平井或垂直井与油藏的接触面积,与钻新井相比,该方案能够显著降低开发成本。在对某个分支井进行密封的作业中,RapidTieBack TAML能够帮助快速、有效的完成多级封堵、射孔(PNP)作业。RapidTieBack TAML还是一款简单、经济的工具,与大多数完井方案兼容,包括水泥/非水泥固井的分支井、可溶解桥塞或常规PNP系统、多级水力压裂系统等。RapidTieBack 没有焊接部件,且整体可堆叠,内径较大,在主油管或分支井中都可使用。

全自动系统协助确定摩擦压力变化

6500型摩擦流动循环回路是一个全自动化系统,可测量不同井筒流体产生的摩擦压力。该系统旨在研究不同的摩擦减速器对压力、酸化、钻完井流体在一定的压力、流量条件和管道直径下的影响。

6500模块通过不同直径的两个测试段来循环流体,从而形成压力vs.流速数据的差异。

这些数据将用于确定测试流体中各种减摩剂的有效性和有效期。6500模块包含一台低剪切渐变腔泵,用于注射基础流体,流量由Coriolis流量计控制。同时,不同的管道流量计都配备高精度压差传感器,用于读取每次测试的多个数据。流体通过可选的计量泵注入,或直接添加到15加仑的油藏搅拌槽中。

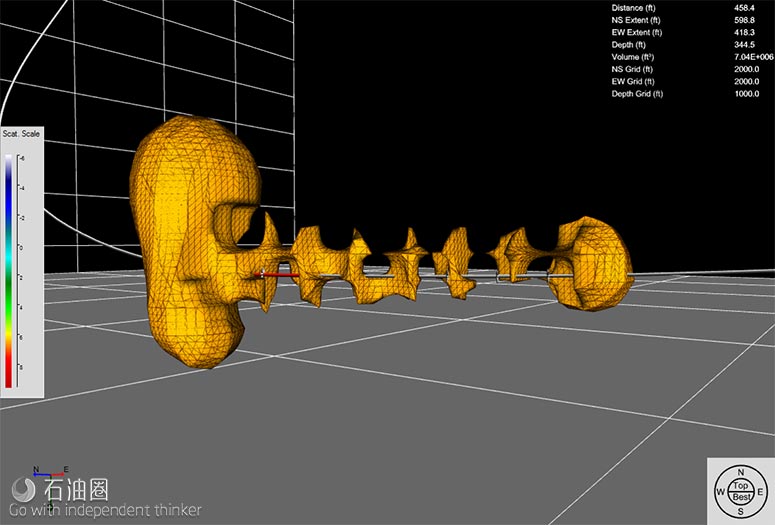

新型系统改进储层中支撑剂方位检测能力

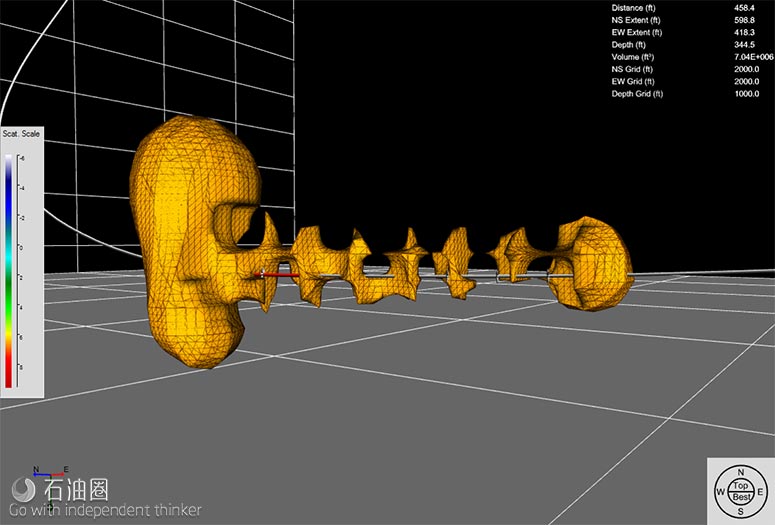

在全球的非常规油藏中,每年大约药消耗1000亿磅的支撑剂,掌握支撑剂的位置对于了解油藏排水、井间距和级间距至关重要。然而,支撑剂方位检测却往往仅限于近井眼测量。CARBO研发了一种能够检测深井处支撑剂的方法,称为QUANTUM量化支撑剂储层体积成像。该方法采用电磁原理,目前正处于现场试验阶段。发射机源和磁场传感器位于地面上,具有独特波形和频率的电流信号通过标准电线单元传输到井筒底部。而一种导电支撑剂则被泵入到有需要的位置。

在检测到支撑剂前后,对电场和磁场进行测量,然后使用全新的分析方法来处理和转化这些不同的数据,以形成被支撑的储层体积图像。QUANTUM旨在确定支撑剂在裂缝中的确切位置,另外还有助于帮助作业者了解井间距、级间距和射孔簇间距、垂直裂缝覆盖面积以及压裂设计变化的影响。

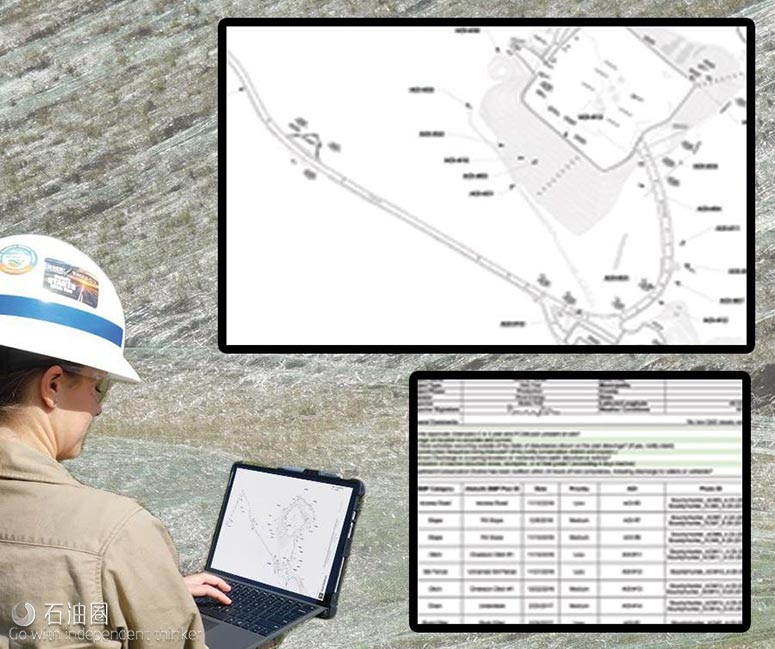

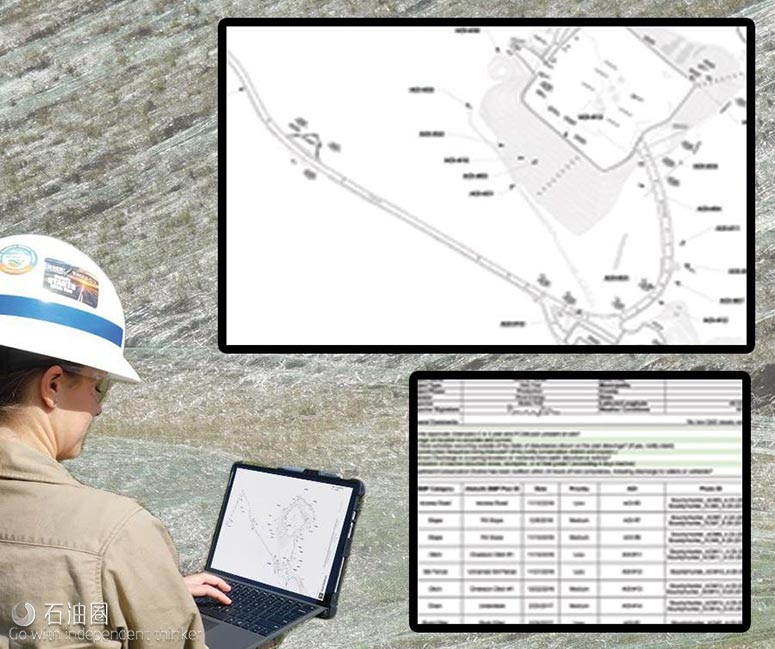

新型数据系统可提高作业人员的文档管理效率

在环保合规和文件的要求和限制下,油气运营商在作业现场需要具备多项许可证,同时,低效的纸质数据存储方式也给他们带来了许多管理挑战。大多数运营商都是将纸质报告和电子邮件相结合来使用。这些文件通常是交付给负责人,并储存在电子邮件目录或纸质文件中。很多运营商都没有将有价值的信息使用起来,审计支持也往往是很混乱的。TruHorizon新的环保合规数据管理应用程序TruData是一个环境和监管数据的中央数据存储库。

结合检测、监控和跟踪三大功能,基于每天的详细检查报支持,TruHorizon的应用程序可提供每日、每周和每月的汇总报告。环保合规数据管理应用可轻松有效地验证任何位置或区域的合规状态。另外,TruData可以提供定制化的数据收集和报告,满足不同运营商的特殊合规性和业务需求。通过使用已收集到的数据,该应用程序可提高运营商对作业合规性的信息,并精简操作,降低维修和维护成本。

下期关键词:增产系统,地面设备

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

柠檬:186-2292-2332;weiyameng@fonchan.com

二丫:131-3255-0596;zhanglingyu@fonchan.com

For English, Please click here (展开/收缩)

CT SYSTEM OFFERS ENHANCED LUBRICITY FOR LONGER LATERALS

Newpark’s ResurreCT system is specifically designed to provide critical lubricity for coiled tubing (CT) operations, especially those with long horizontal laterals such as shale stringers. Achieving lateral length requires lubricity to reduce the friction of metal-to-metal contact. Longer lateral lengths also require controlling the torque and drag forces, which determine the number of trips and tool runs and, ultimately, the well cost. The lubricant for the ResurreCT system is designed to address this critical issue in CT operations. DireCT, the effective pipe-on-pipe friction reducer in the ResurreCT system, was evaluated for wear and steady-state coefficient of friction using a Falex Block-on-Ring Test. The lower coefficient of friction properties provided by the proprietary lubricant enhances the CT operations, allowing increased weight on bit and a reduction in the number of trips required for a successful CT operation. Operational and engineering gains provide significant value to the customer. The ResurreCT system is effective in a wide variety of densities and is thermally stable at temperatures greater than 204℃(400℉).

TOOLS ENABLE ENHANCED SHALE INTERVENTION, STIMULATION APPLICATIONS

National Oilwell Varco (NOV) has released several products that are designed to enable greater performance in shale intervention and stimulation applications. The CTES Condition-Based Monitoring (CBM) System and the Texas Oil Tools Stack Monitor are real-time monitoring systems for intervention and stimulation equipment. The CBM System monitors the health of pumps, bearings, filters and engines as well as hydraulic power and lubrication systems. The Stack Monitor provides real-time data on the entire BOP stack, allowing monitoring of the rams’ positions, latch-and-lock systems and stripper pressures. Early identification of potential failures improves uptime and reduces maintenance costs while ensuring safety and efficiency at the well site. Quality Tubing QT-1400 is the next generation of ultrahigh-strength coiled tubing (CT). With minimum yield strength of 140 kilopounds per square inch, QT-1400 is the strongest CT on the market, according to NOV. With greater resistance to low-cycle fatigue cracking at high pressure, QT-1400 is ideal for shale applications. CT that can withstand harsh downhole environments is critical in increasingly challenging horizontal wells with longer lateral sections, refracturing applications and deepwater operations.

INCREASE RESERVOIR CONTACT WHILE MINIMIZING CAPEX

As shale development matures and operators seek new ways to improve recovery from limited acreage and declining budgets, multilateral well technology adds an economic lifeline for adding new infill wells while maintaining existing assets. The Schlumberger RapidTieBack TAML 3 or 4 conventional multilateral junction enables selective, repeatable entry and isolation for efficient multistage stimulation in wells with multiple laterals. Its high hanging capacity enables operators to maximize reservoir contact in long horizontal or vertical intervals with minimal location footprint and with greatly reduced capex investment as compared to drilling new wells from the surface. In operation a sealbore connection isolates the selected lateral, enabling efficient plug-and-perf (PNP) multistage operations. Simple and cost-effective, the RapidTieBack multilateral junction is compatible with many completion options, including cemented or uncemented laterals, dissolvable and conventional PNP systems, and hydraulic multistage fracturing. It has no welded components and is fully stackable, with large inner diameter access to both the main and lateral bores.

SYSTEM HELPS DETERMINE FRICTION PRESSURE CHANGES

The Model 6500 Friction Flow Loop is a fully automated system that measures the friction pressure created by different wellbore fluids. The system is designed to study the effect different friction reducers have on fracturing, acidizing, completion and drilling fluids over a range of pressures, flow-rate conditions and pipe diameters. The Model 6500 circulates fluid through two test sections of various diameters to generate differential pressure vs. flow-rate data. These data are then used to determine the effectiveness and longevity of various friction-reducing agents added to the test fluids. The Model 6500 incorporates a low-shear progressive cavity pump for injection of base fluids, with the flow rate controlled by a Coriolis flowmeter. High-accuracy differential pressure transducers are provided for each tubing diameter for multiple data readings per test. Fluid can be injected into the flowstream via an optional metering pump or added directly into a 15-gal reservoir mixing tank.

SYSTEM IMPROVES ABILITY TO DETECT LOCATION OF PROPPANTS IN RESERVOIR

About 100 billion pounds mass of proppant is used annually in global unconventional reservoirs, with the location of the proppant critical to understanding reservoir drainage, well spacing and stage spacing. However, proppant detection has traditionally been limited to near-wellbore measurements. CARBO has developed a method to detect proppant in the far field, known as QUANTUM quantified propped reservoir volume imaging. The QUANTUM method, now in the field trial phase, uses electromagnetic principles. A transmitter source and an array of electric and magnetic field sensors are located at the surface, and a current signal with a unique wave form and frequency is transmitted to the bottom of the wellbore via a standard electric line unit. An electrically conductive proppant is pumped into the stages of interest. The electric and magnetic fields are measured before and after the detectable proppant stages, and a novel analysis method is then employed to process and invert these differenced data to create an image of the propped reservoir volume. QUANTUM is designed to identify the exact location of proppant in fractures. The program also assists in understanding well drainage and spacing, stage and perforation cluster spacing, vertical fracture coverage, and the impact of fracture design changes.

DATA SYSTEM ENHANCES DOCUMENT MANAGEMENT FOR OPERATORS

Environmental compliance and documentation can present numerous management challenges for oil and gas operators faced with multiple permits required at the work site and inefficient, paper-based data storage. Most operators use some combination of handwritten scanned paper reports and emailed spreadsheets from the field. These documents are typically delivered to the responsible person and stored in an email directory or a physical paper file. Every operator has valuable information it is not using, and audit support often is chaotic. TruHorizon’s new environmental compliance data management application, TruData, is a central digital repository for environmental and regulatory data. Incorporating inspection, monitoring and tracking, TruHorizon’s application has robust daily, weekly and monthly summary reporting supported by daily detailed inspection reports. The environmental compliance data management application easily and effectively verifies the compliance status of any location or geographic area. TruData can provide custom data collection and reporting to meet the unique compliance and business needs of the operator. Improved confidence in compliance, streamlined operations and reduced cost of repairs and maintenance results from using the data already being collected.

未经允许,不得转载本站任何文章:

石油圈

石油圈